79

17

1

1

1816

14

1

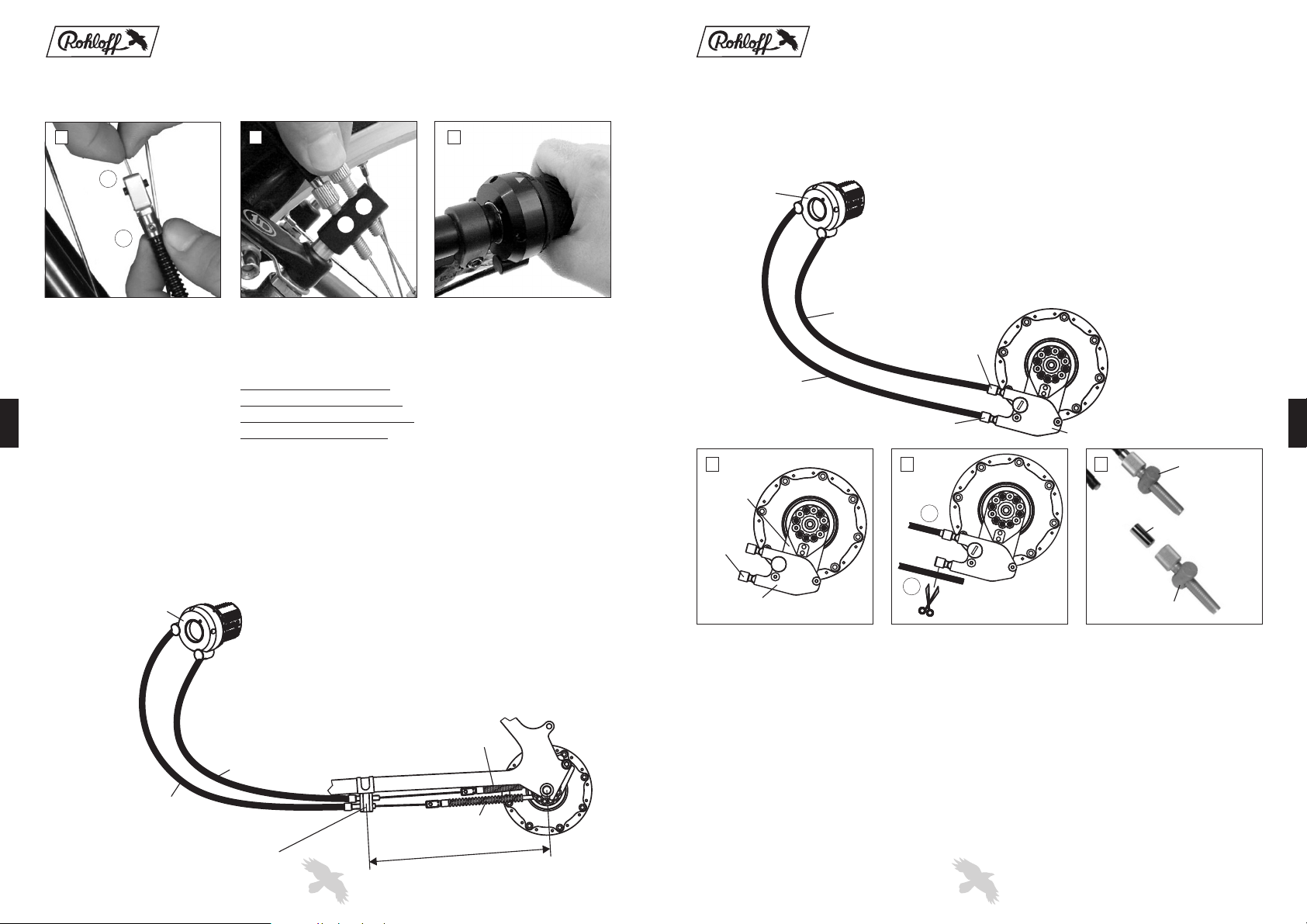

Twistshifter

Hubcable1

Hubcable14

Cableguide0°

(Art.#8260)

Longer240mm

Shiftercable 14

Shiftercable1

Turnthetwistshifterbackand

forthseveraltimestomakesure

thattheshiftercablesaresitting

correctlywithinthecableguides.

Windingoutthecableadjusters

increasestheshiftertension,

windingthecableadjustersin

decreasestheshiftertension.

For alighter shifting,setthe

cabletension(bytheuseofthe

cableadjusters),sothatthetwist

shifter hasabout2mmplay.

Bypullinghubcable1,thegearboxshiftsgearsindirectionof

gear#1(smallergears).Bypullinghubcable14,thegearbox

shiftsgearsindirectionofgear#14(largergears).Hubcable1

liesinthelowerpositionatthegearboxandatthefrontposition

onthetwistshifter.Hubcable14liesinthehigherpositionat

thegearboxandattherearpositiononthetwistshifter. The

connectingoftheshiftercablestothehubcablesisexplainedin

chapter7.2.1

7.2.2 Cable routing via the chainstay

When routing the shifter cables via the chainstay, the 0° cable guide (Art. #8260) must be mounted at a minimum

distance of 240mm away from the hub's axle. This should be mounted in a position, so that the hub cables run in the

straightest line possible towards the shifter cables.

Checkthatall14gearsare

available(14gears=13clicksof

thetwistshifter)byrotatingthe

twistshifterforwardstotheend

stop(gear#14)andbackwardsto

theendstop(gear#1).

Mounting

Openthemale/femaleconnectors

ofcables14,sothatjoiningshifter

cable1withafemaleconnector

becomeseasier.Placethefemale

connectoroverthemalebayonet

connectorandthreadtheshortened

shiftercable1fullyintotheholeof

thebayonetconnector1(10mm

deep),tightenuptheheadless

screws.Rejointhedisconnected

cables14.

80

1 3

1

14

2

7.3 External gear mech

7.3.1 Cable routing via the chainstay

Withtheexternalgearmech,theshiftercablesrununinterruptedfromthetwistshiftertothethecablebox,for

thisreason,thereisnoneedforaseparatecableguide. Thegearmechanismiscontrolledbythecableboxwhich

sitsontheexternaltransferbox,mounteddirectlyonthehub.

Securethecableboxtothe

externaltransferbox(which

shouldbeinthecorrect,pre-

adjustedposition)withtheknurled

headedscrew.Insertthetwocable

adjustersintothecablebox. The

diagramshowsthegeartransfer

boxmountedinlinewithanOEM

axleplatebutthetypeandposition

ofaxleplatecanvaryfromthat

illustrated.

Routetheshiftercablesfromthe

twistshifterinthedirectionofthe

cableboxandcutthehousingto

theappropriatelengthandmounta

cablehousingcaponeachend.

Inserttheshiftercablecompletely

intothecablehousingandcheck

thatthecablehousingissitting

correctlyinallcablestops.Donot

mountthecableadjusteryet.

Bypullinghubcable1,thegearboxshiftsgearsindirectionof

gear#1(smallergears).Bypullinghubcable14,thegearbox

shiftsgearsindirectionofgear#14(largergears).

Hubcable1liesinthelowerpositionatthecableboxandatthe

frontpositiononthetwistshifter.Hubcable14liesinthehigher

positionatthecableboxandattherearpositiononthetwist

shifter.

Twistshifter

Shiftercable1

Shiftercable14

Cableadjuster 14

Cableadjuster 1 Cablebox

External

transfer

box

Cable

adjuster

Cablebox

Mounting

Cableadjuster

Cablehousingcap

Mounted

cableadjuster

(later)