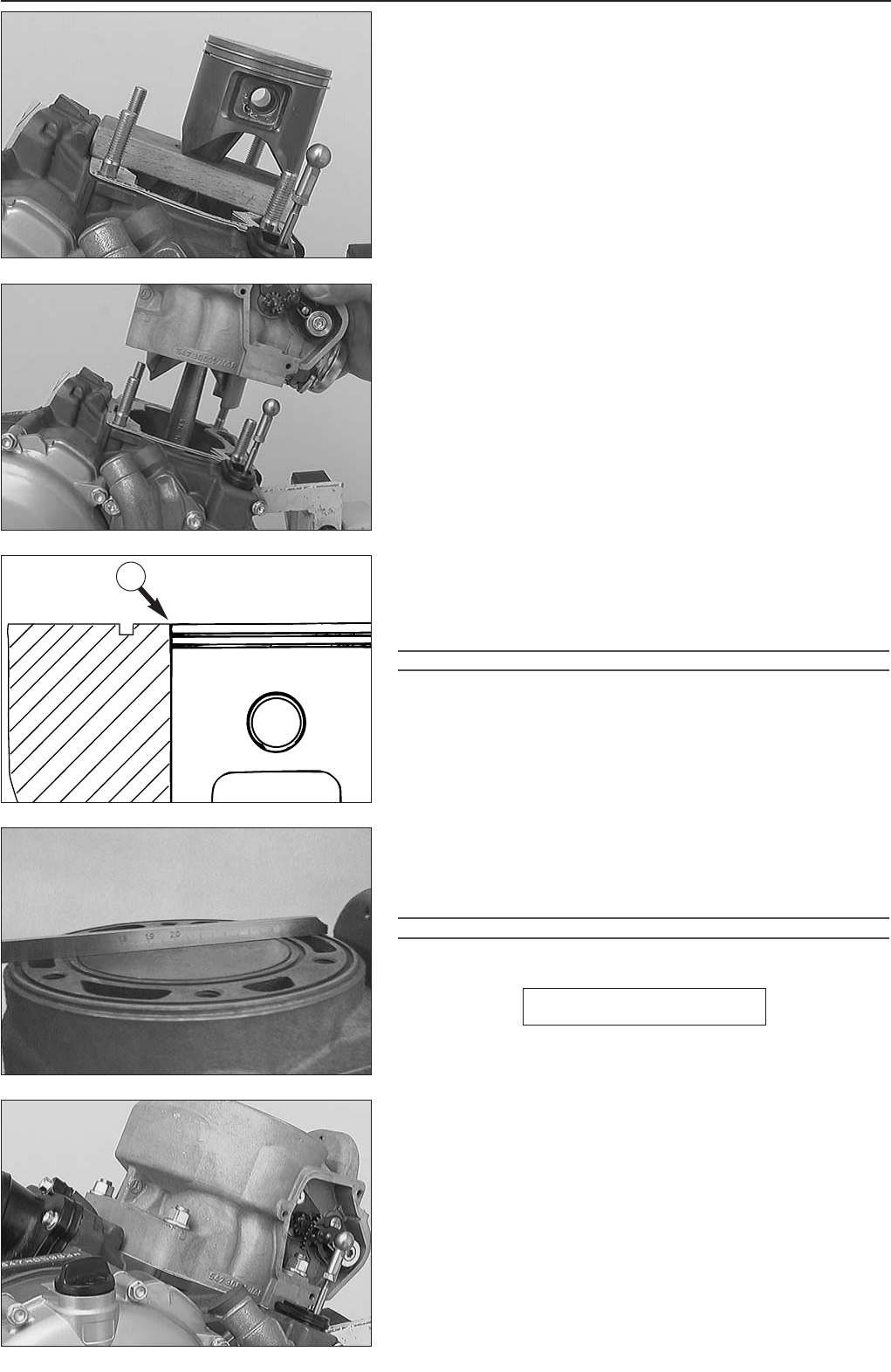

Mounting piston and cylinder

– Before assembly, oil all parts thoroughly at the sliding points.

– Insert needle bearing in conrod eye, mount piston (arrow on piston

head shows direction for exhaust duct).

– Mount piston pin and wire circlips with open side showing downwards

(see sketch).

– Mount cylinder base gaskets.

– Place piston on selfmade wooden stand and position piston ring.

– Place on preassembled cylinder, remove wooden stand and tighten

cylinder down crosswise, using two nuts.

Adjusting dimension „X“

Dimension „X“ is the dimension from upper edge of piston to upper edge

of cylinder with cylinder under low tension and piston in TDC position.

The dimension „X“ should be adjusted extremely carefully by inserting

cylinder base gaskets of suitable thicknesses.

!

CAUTION

!

I

F THE DIMENSION „X“ IS TOO LARGE, THE COMPRESSION RATIO WILL BE REDUCED

AND THE ENGINE LOOSES POWER

. ON THE OTHER HAND, IF THE DIMENSION „X“ IS

TOO SMALL

,

THE ENGINE WILL PING AND OVERHEAT.

– Set the piston to TDC, and apply a sliding gage or straight-edge to the

cylinder. Now, check the distance between the piston's upper edge

and the sliding gage. This distance should be from 0 mm to 0.10 mm

at the most. It can be corrected, if necessary, by adding or removing

of cylinder-base gaskets.

!

CAUTION

!

T

HE PISTON MUST NOT PROTRUDE BEYOND THE CYLINDER'S UPPER EDGE.

– Mount the 2 remaining collar nuts at the cylinder base, and tighten

each of the 4 collar nuts to 35 Nm (27 ft.lb.).

6-7C

Dimension „X“ = 0 mm

+ 0,1 mm

X