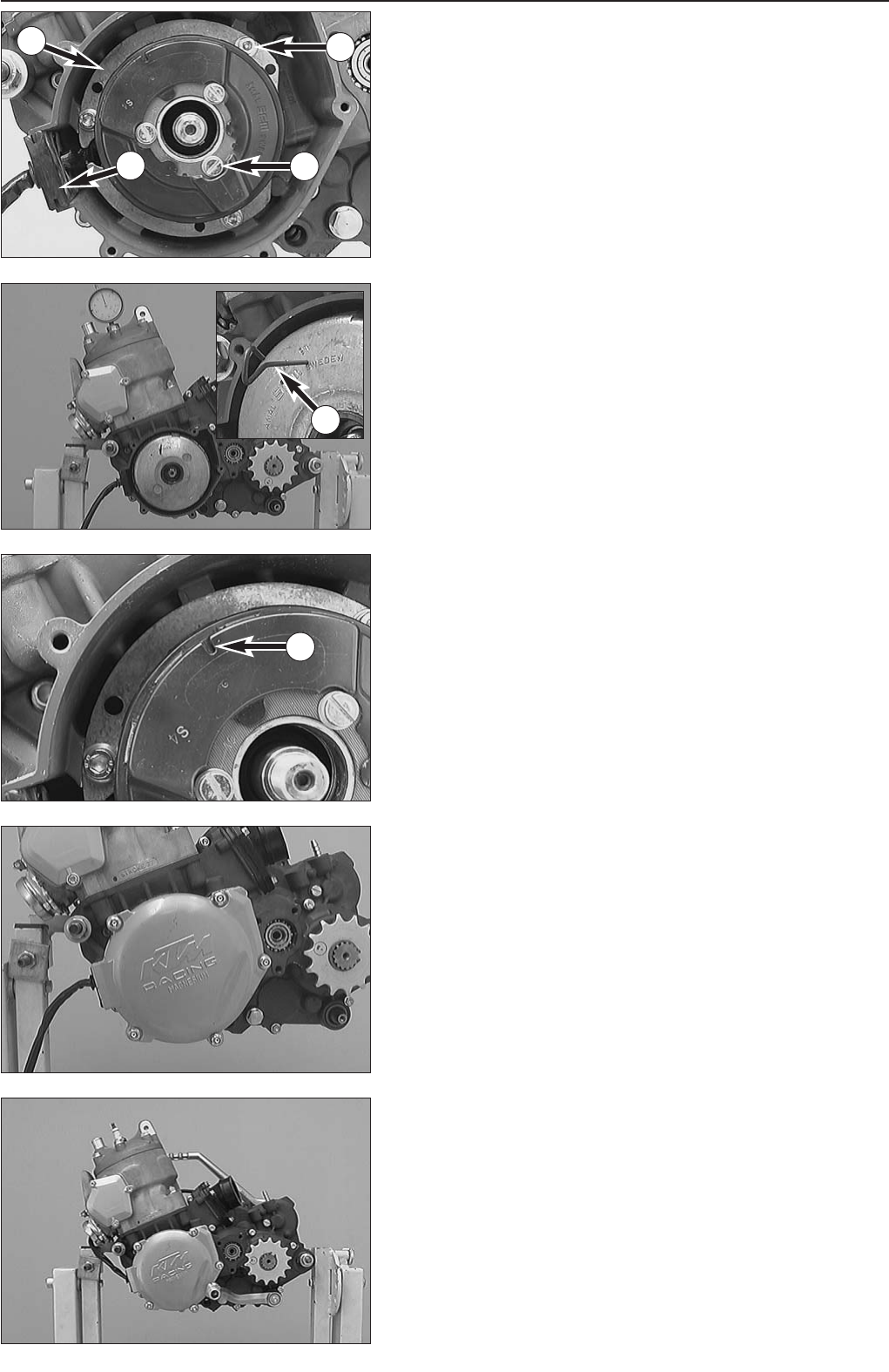

Mounting the ignition (SEM)

– Insert woodruff key into crankshaft.

– Apply Loctite 243 to the threads of the 3 screws

2.

– Mount base plate

1 together with stator, and tighten the 3 screws.

– Mount the cable guide

3 into the cutaway portion of the casing.

– Mount the rotor.

– Mount the detent edged ring and the nut.

– Hold the rotor with the holding spanner and tighten the nut with 60

Nm (45 ft.lb.).

Adjusting ignition point (SEM)

– Make sure that the stator can be turned on the intermediate plate.

Otherwise, loosen the 3 screws

4.

– Mount flywheel.

– Screw dial gauge into spark plug thread.

– Place adjusting pin

5 in flywheel bore (“91“) 2 mm (0.08 in) and turn

flywheel until pin slots into recess

6 in stator.

–Turn flywheel and stator jointly to TDC.

–Turn dial gauge scale to 0 and turn flywheel with stator clockwise

accordingly to preignition.

Ignition point:

– Carefully remove flywheel to prevent further turning of stator.

–Tighten the three stator cylinder screws.

– Mount flywheel and tighten collar nut with 60 Nm (45 ft.lb).

– Check ignition point once more.

– Remove dial gauge and fit spark plug with OR.

Mounting ignition cover

– Put on a new gasket, and fix the ignition cover by means of the 5

screws.

Mounting starting lever and shift lever

– Push distance bushing onto kickstarter shaft and mount kickstarter.

– Mount shift lever.

– Operate the kickstarter a few times and check if the engine turns

freely.

– Oil the push rod, and insert it into the drive shaft.

NOTE: The transmission oil should be filled in only after the engine has

been mounted. Otherwise, a part of the transmission oil would leak out

through the drive shaft.

6-11C

1

2

4

3

5

6