Machine Overview .................................................................. 5

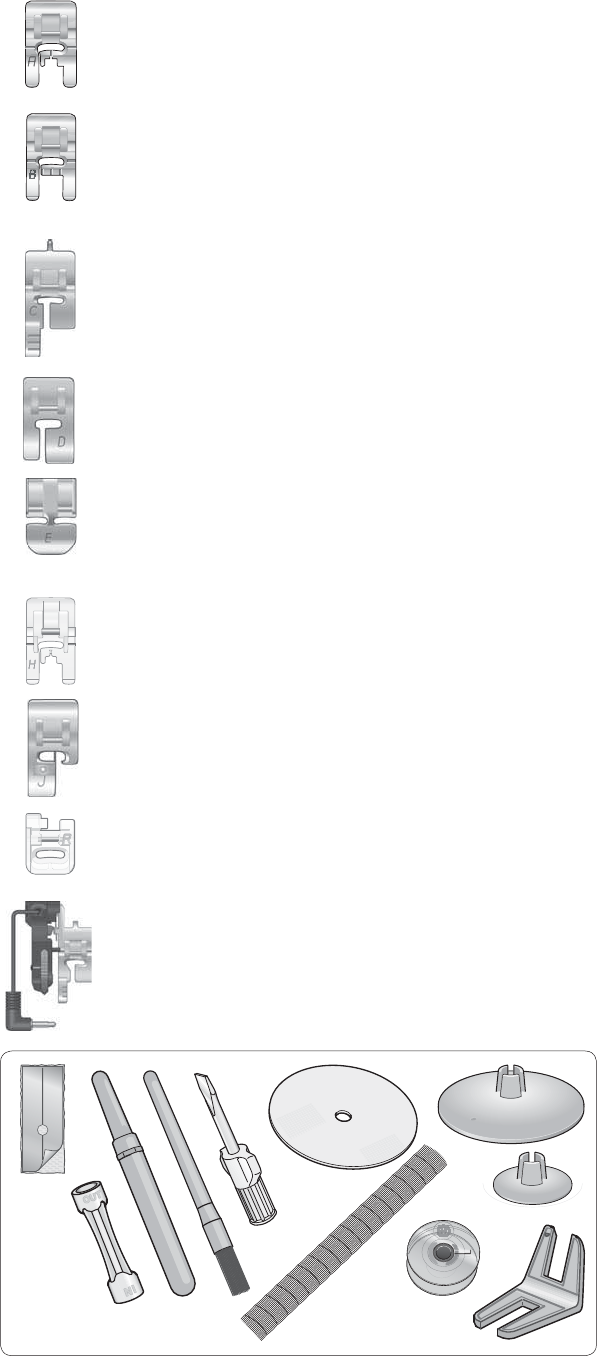

Included Accessories .............................................................. 6

G ting Ready To Sew

Unpacking ................................................................................. 7

Packing away after sewing ..................................................... 7

Accessory box ......................................................................... 7

Extended Sewing Surface ...................................................... 7

Using the free arm .................................................................. 7

Connecting the foot control cord....................................... 8

Connect the power cord and foot control ....................... 8

Lower the feed teeth ............................................................. 8

Changing the presser foot..................................................... 9

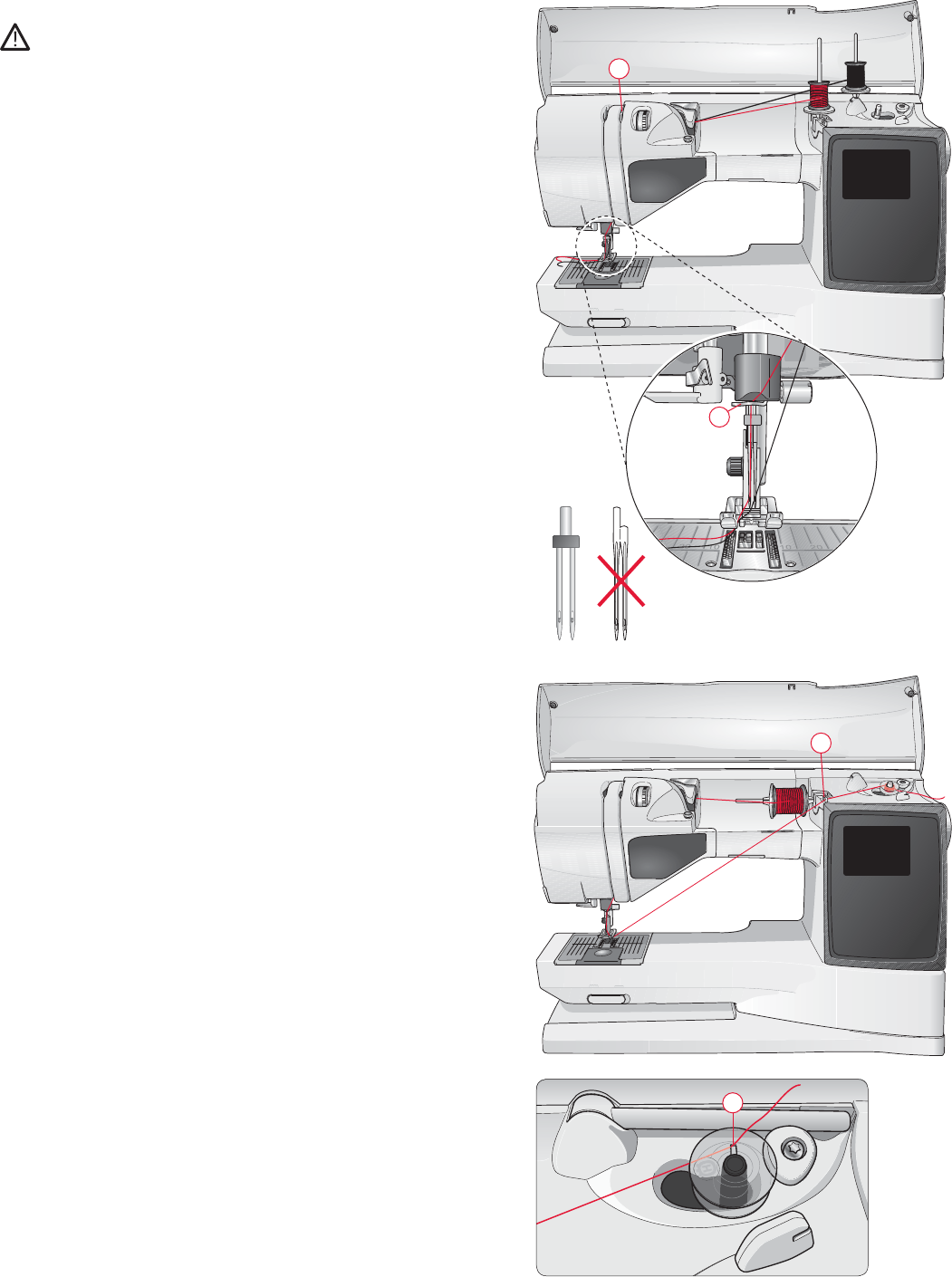

Changing the needle ............................................................... 9

Needles ..................................................................................... 9

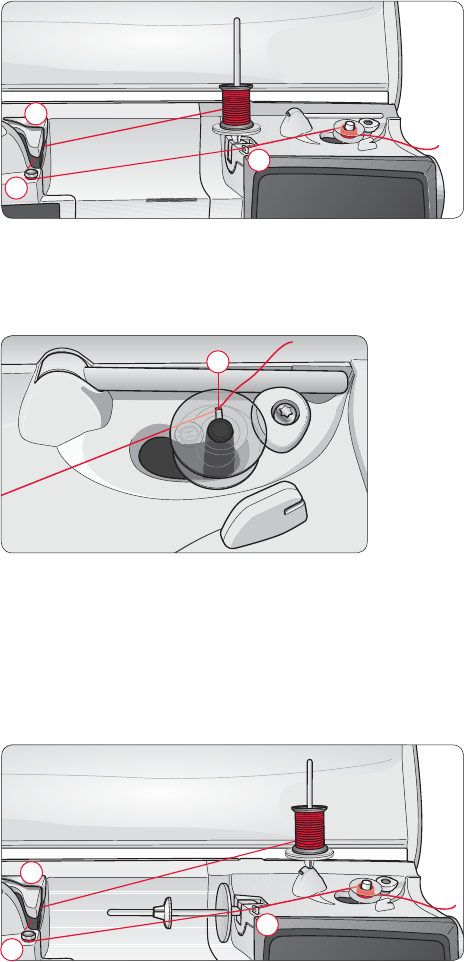

Spool pins and spool caps ...................................................10

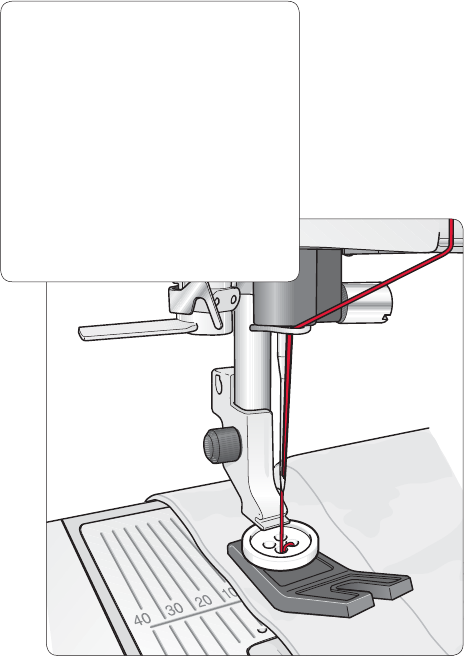

Threading the upper thread................................................11

Needle threader ....................................................................12

Cutting the thread ................................................................12

Threading for twin needles .................................................13

Winding the bobbin ........................................................13-14

Inserting the bobbin .............................................................15

Thread tension.......................................................................15

EXCLUSIVE SENSOR SYSTEM™ (ESS) ..........................16

Sensor Foot Pressure .........................................................16

Sensor Foot Lift ..................................................................16

Starting to sew .....................................................................16

Operating e Ma ine

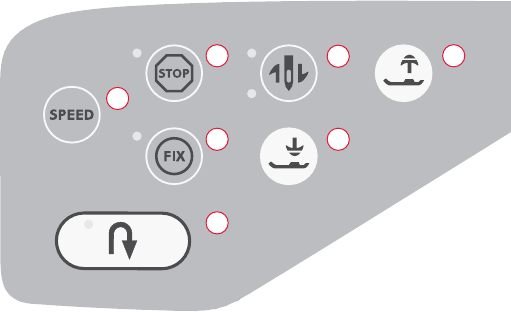

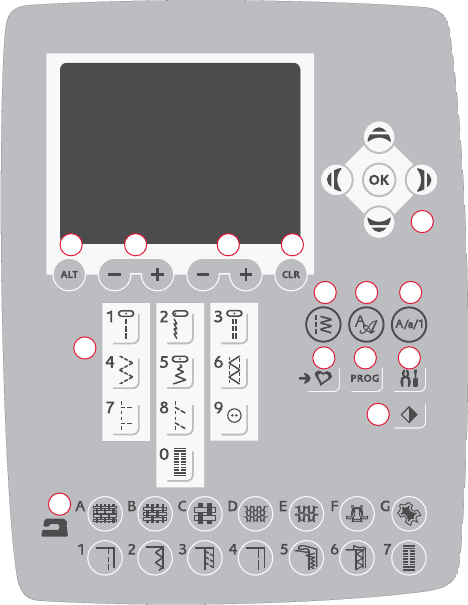

Function buttons ...................................................................17

Needle Stop Up/Down .....................................................17

Sensor Foot Up/Extra Lift ...............................................17

Sensor Foot Down/Pivot Position ..................................17

STOP ....................................................................................17

Speed ....................................................................................17

FIX .......................................................................................17

Reverse .................................................................................17

Function buttons on the Touch Panel ...............................18

Alternate View ....................................................................18

Stitch Length/Density .......................................................18

Stitch Width/Needle position ..........................................18

Clear ......................................................................................18

Stitch Selection Buttons ....................................................18

Navigator Arrow Buttons .................................................18

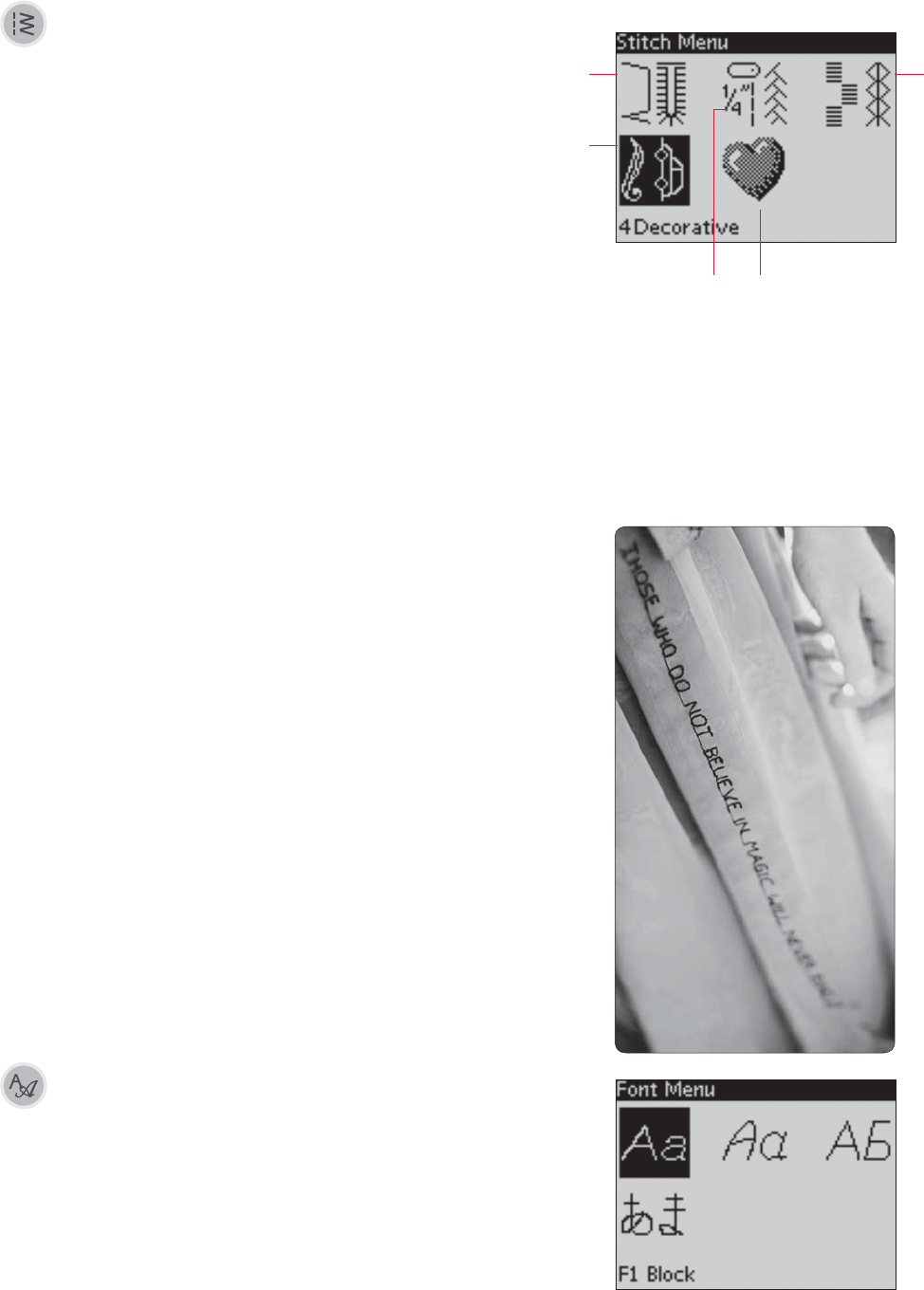

Stitch Menu .........................................................................18

Font Menu ...........................................................................18

Shift to upper-case, lower-case or numbers ...................18

Save to My Stitches ............................................................18

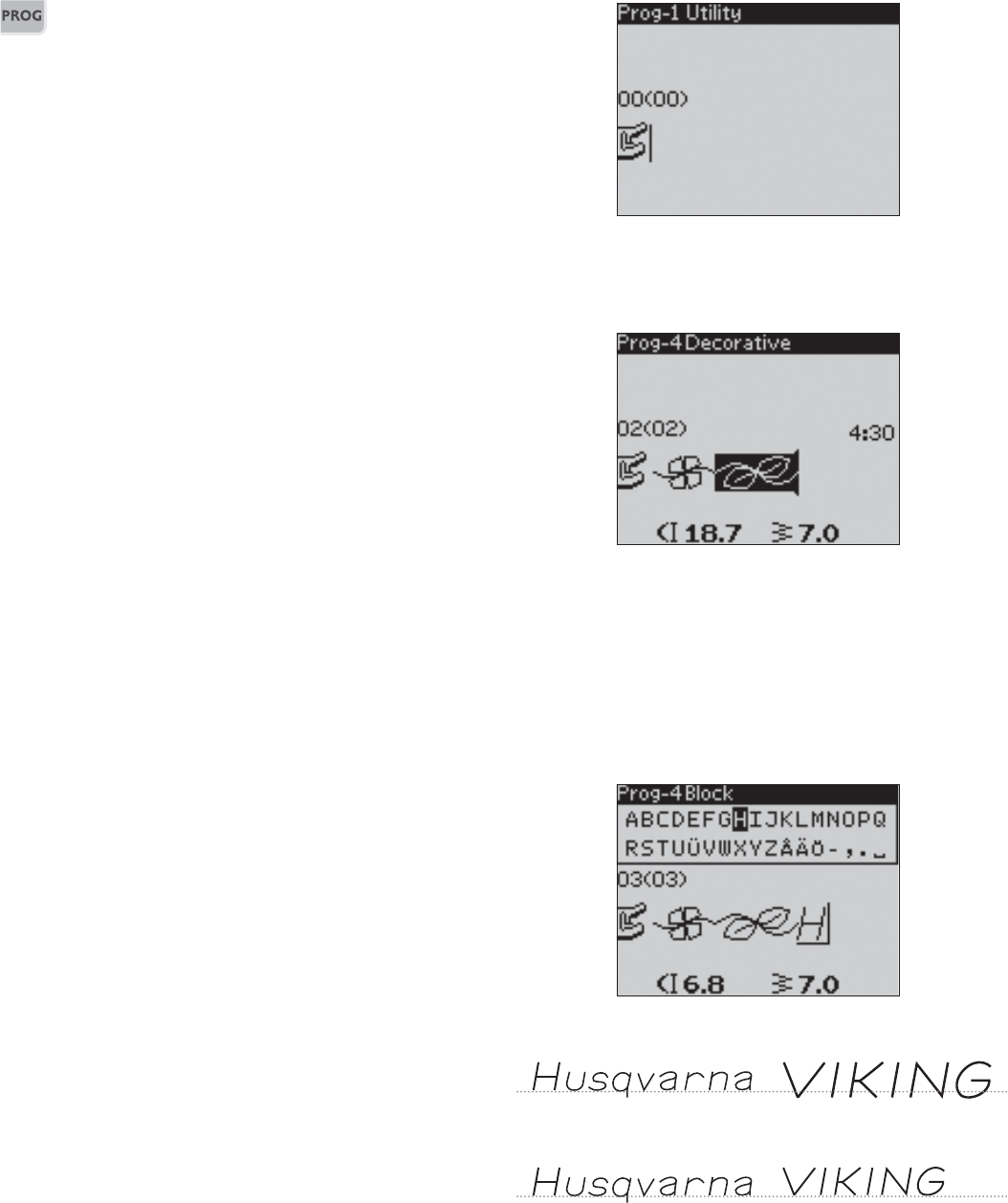

Program Mode ....................................................................18

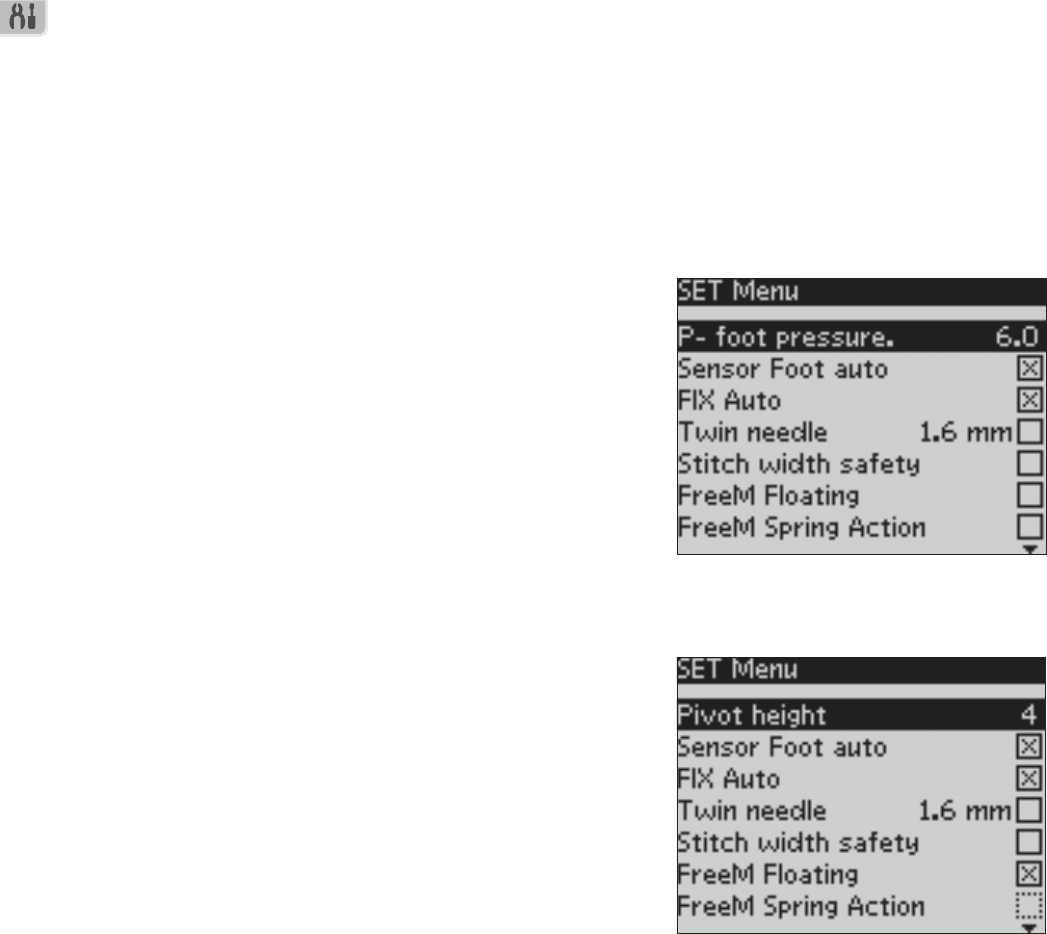

SET Menu ...........................................................................19

Mirror Side to Side .............................................................19

Exclusive SEWING ADVISOR™ ..................................19

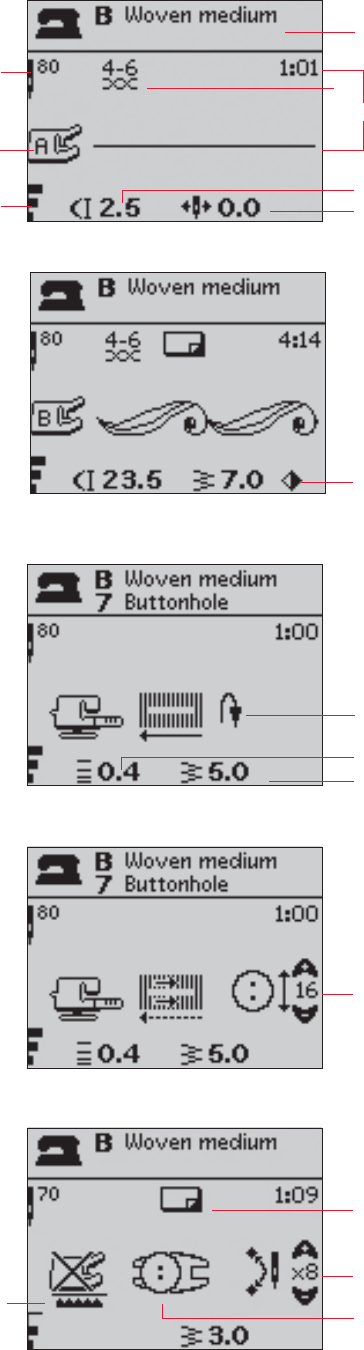

Sewing Mode ..........................................................................20

Selecting a Stitch ................................................................21

Selecting a Font .................................................................21

Programming ..................................................................22-24

SET Menu ...............................................................................25

Presser Foot Pressure ........................................................25

Pivot Height ........................................................................25

Sensor Foot Auto ...............................................................25

FIX Auto .............................................................................25

Twin Needle ........................................................................25

Stitch Width Safety .............................................................25

Free Motion Floating .........................................................26

Free Motion Spring Action ...............................................26

Buttonhole Balance ............................................................26

Audible Alarm .....................................................................26

Contrast ................................................................................26

Language ..............................................................................26

Software Version.................................................................26

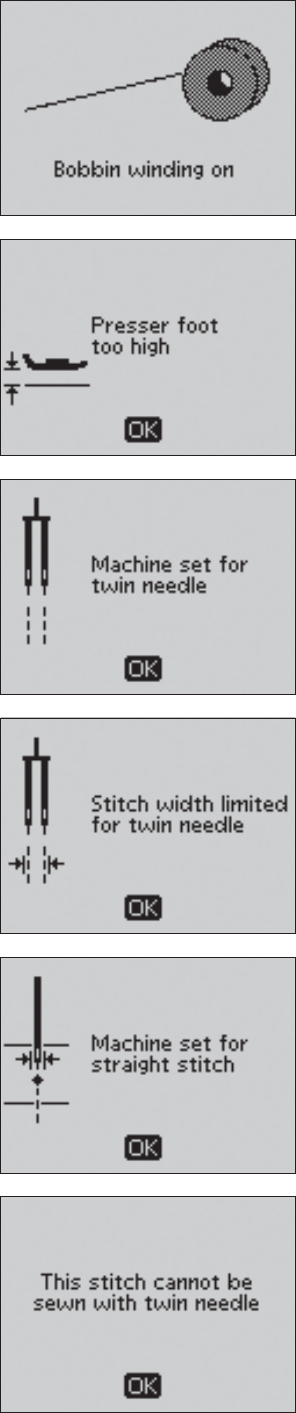

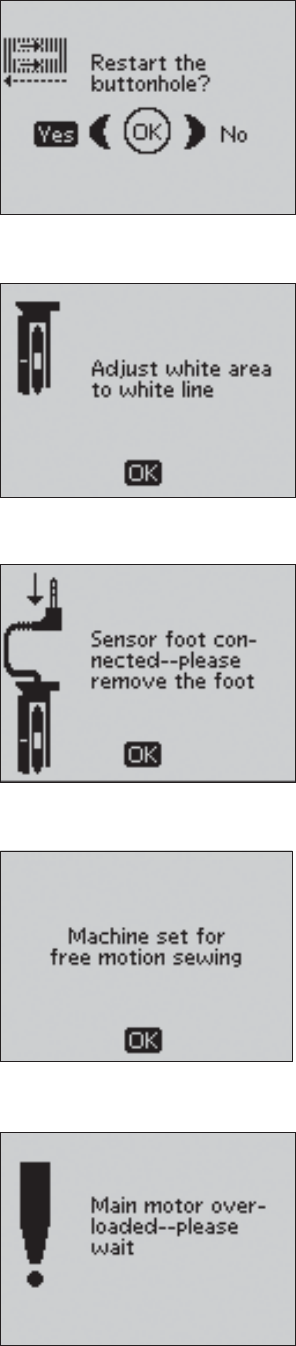

Pop-up messages ...................................................................27

Basic Sewing Te nique

Exclusive SEWING ADVISOR™ .......................................30

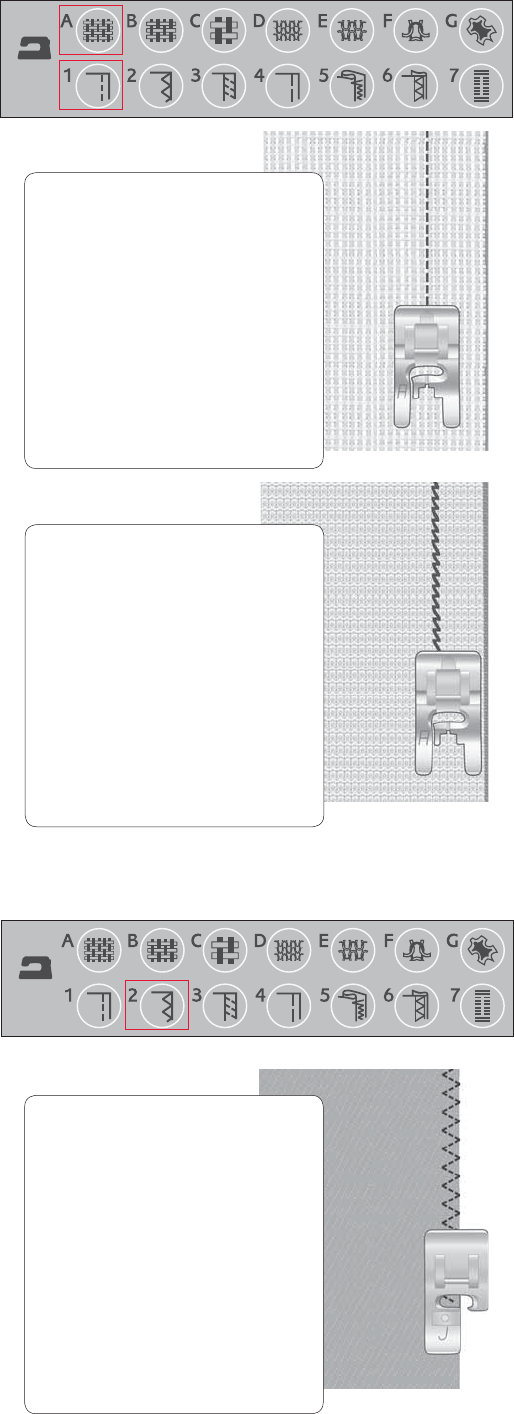

Seam .........................................................................................31

Overcast ..................................................................................31

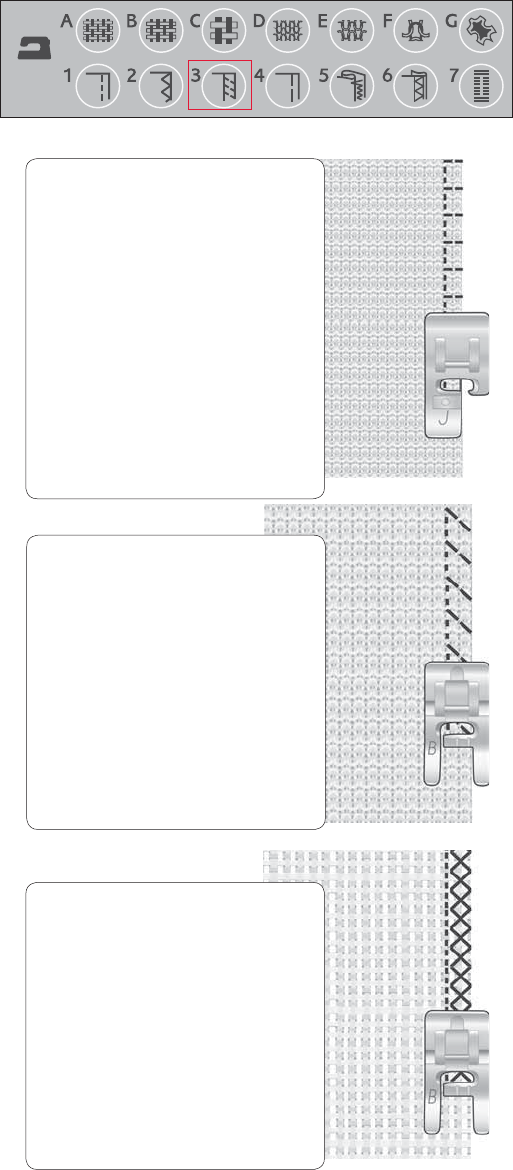

Seam and overcast ................................................................32

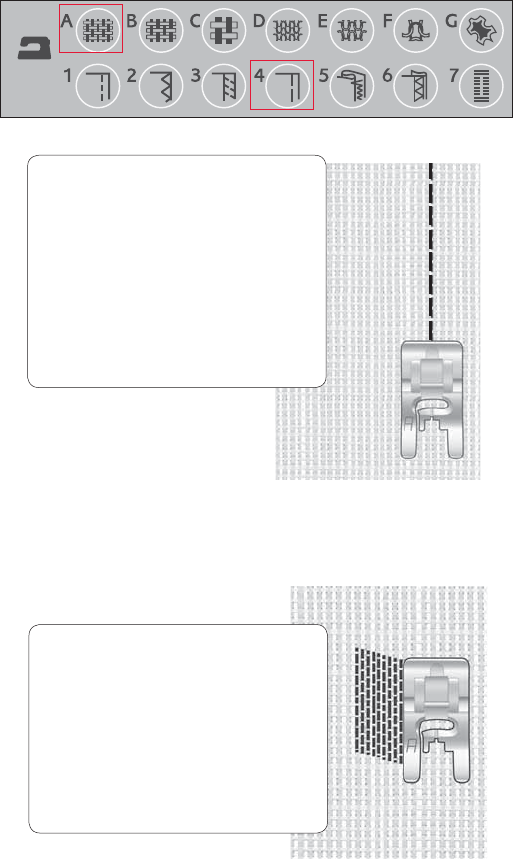

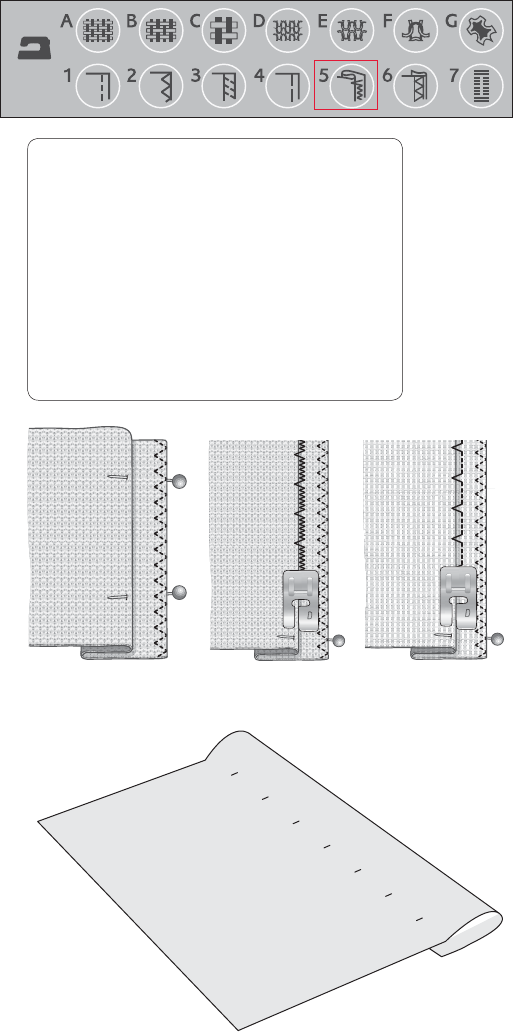

Baste .........................................................................................33

Darning and mending ...........................................................33

Blind hem ................................................................................34

Hem..........................................................................................35

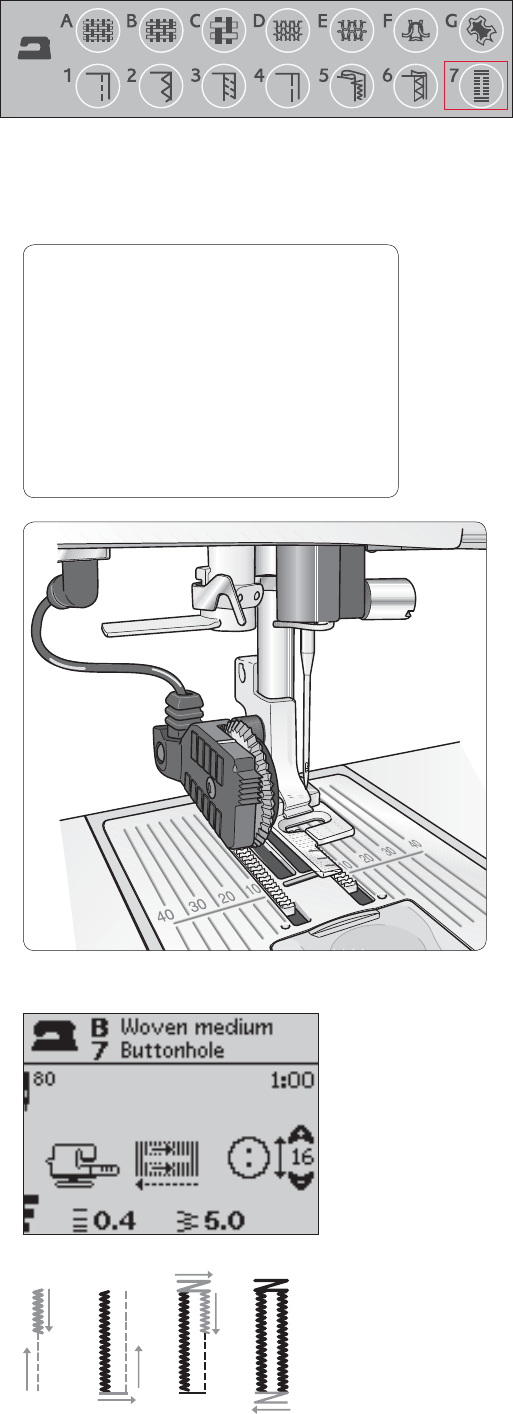

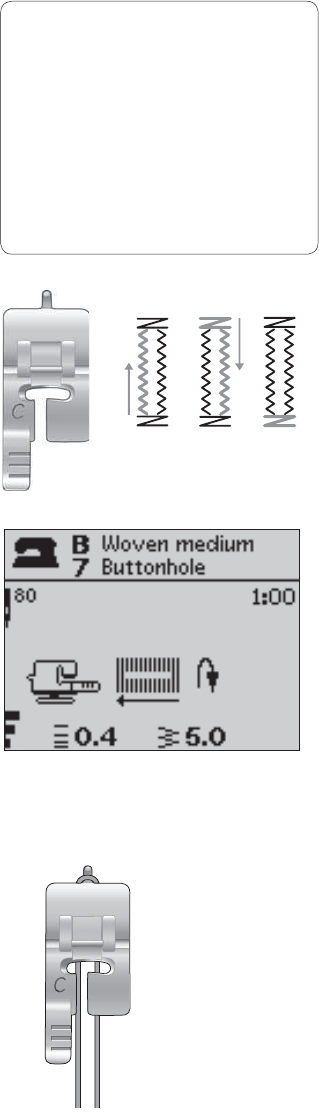

Sewing buttonholes ..............................................................36

Sewing on buttons ................................................................38

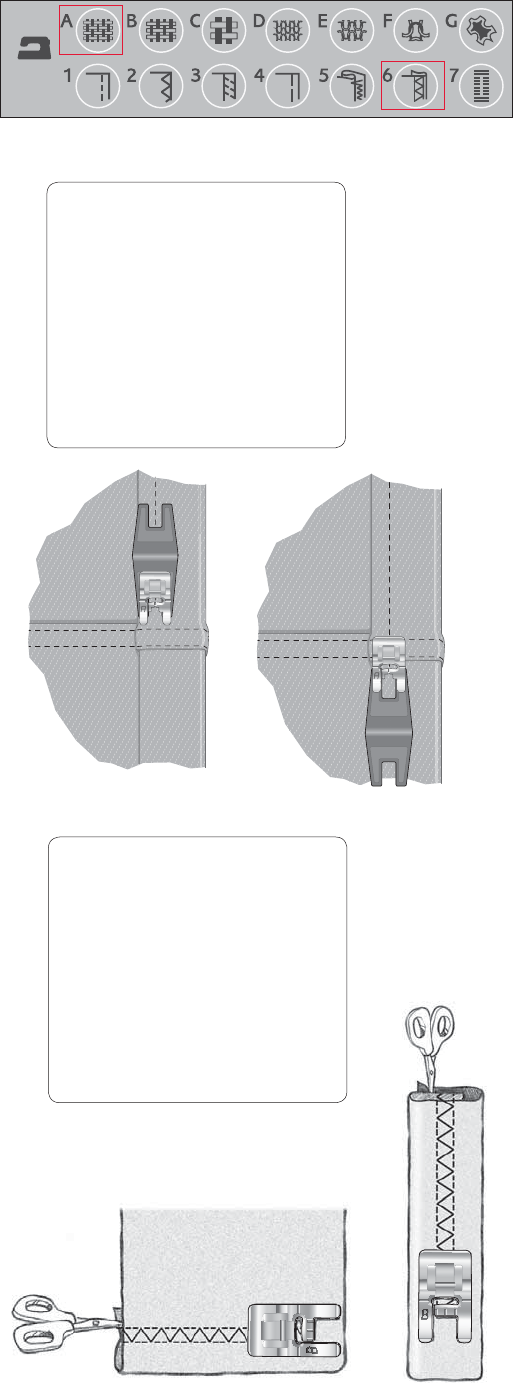

Sewing zippers .......................................................................39

Free Motion Quilting ............................................................ 40

Taking Care of the Ma ine

Changing the light bulbs.......................................................41

Cleaning the machine ...........................................................41

Clean the Bobbin Area ......................................................41

Cleaning Under the Bobbin Area ....................................41

Replacing the Stitch Plate ..................................................41

Trouble shooting ................................................................... 42

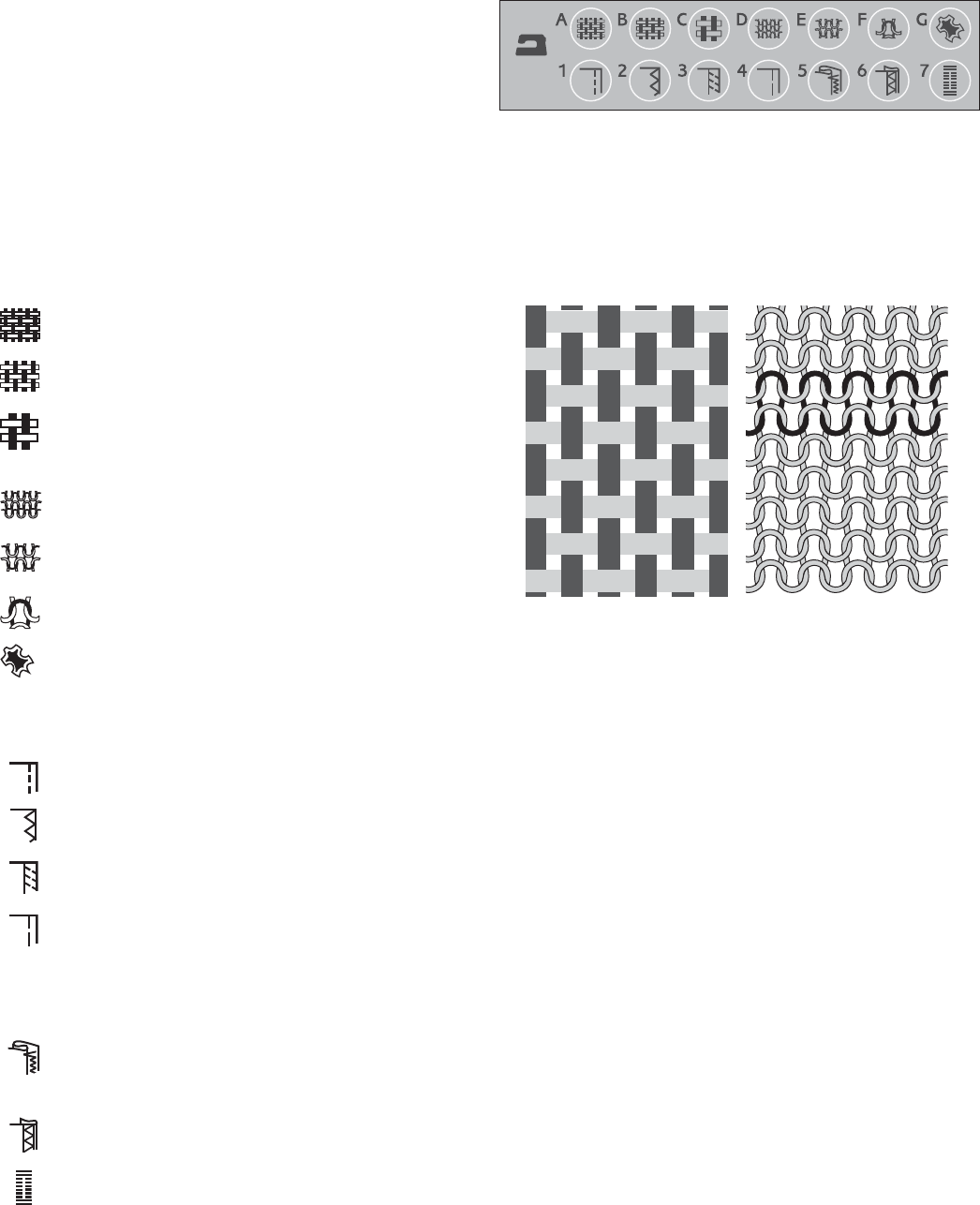

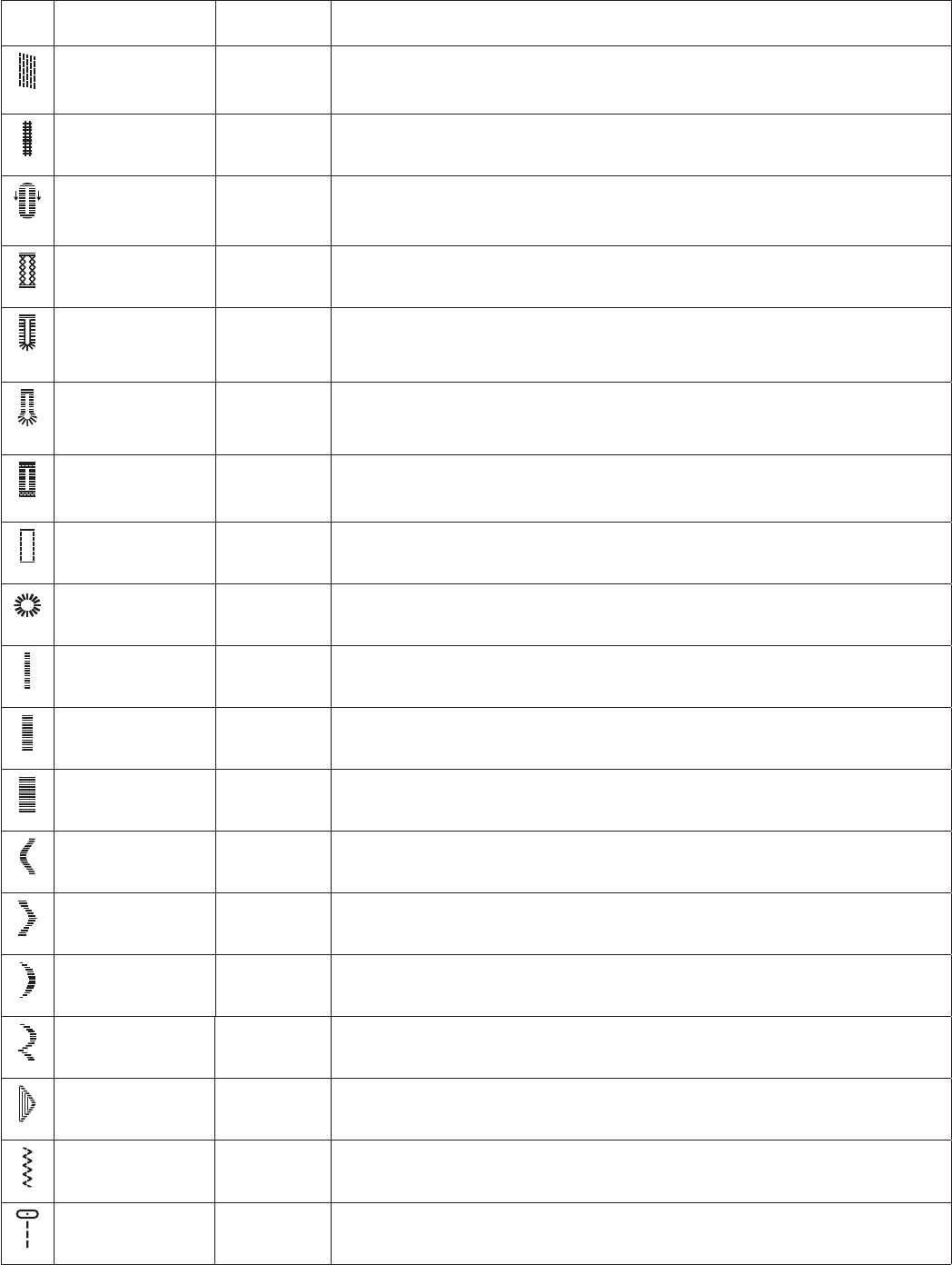

Stitch table - menu 1, Utility Stitches ............................... 44

Stitch overview ...................................................................... 46

Alphabets ................................................................................46

CONTENTS