3

CONTENTS

PUMP SAFETY............................................................................5

IMPORTANT SAFETY INFORMATION .........................................5

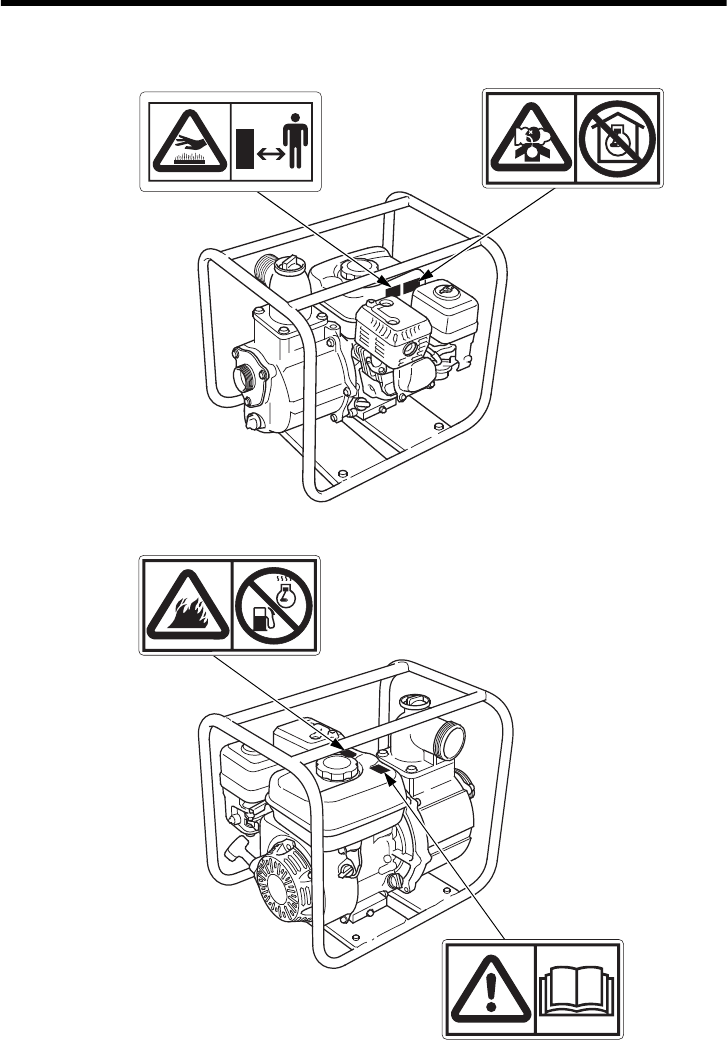

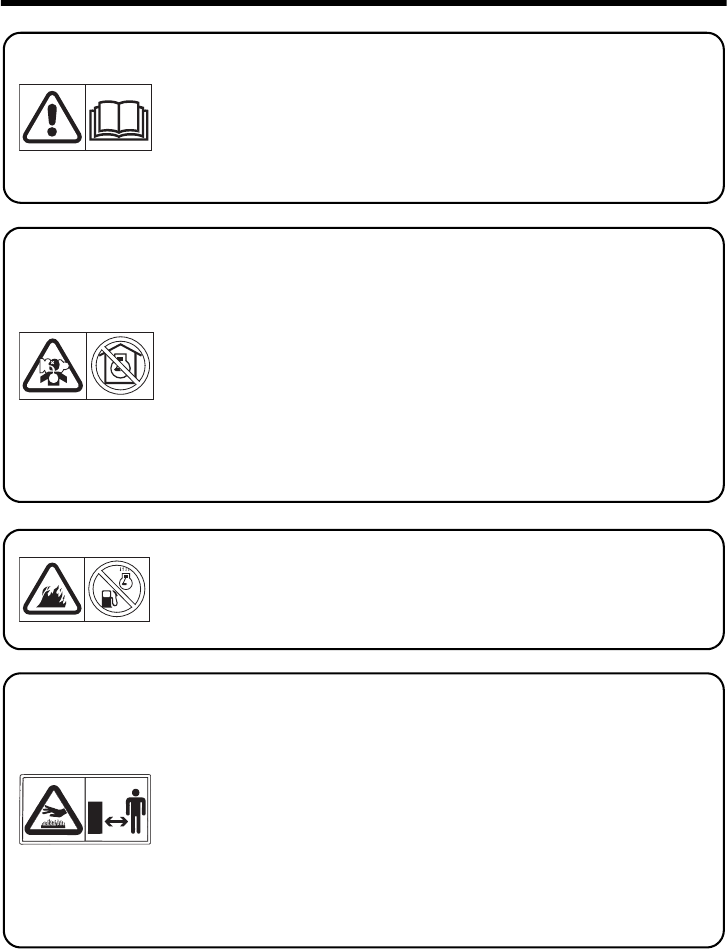

SAFETY LABEL LOCATIONS......................................................7

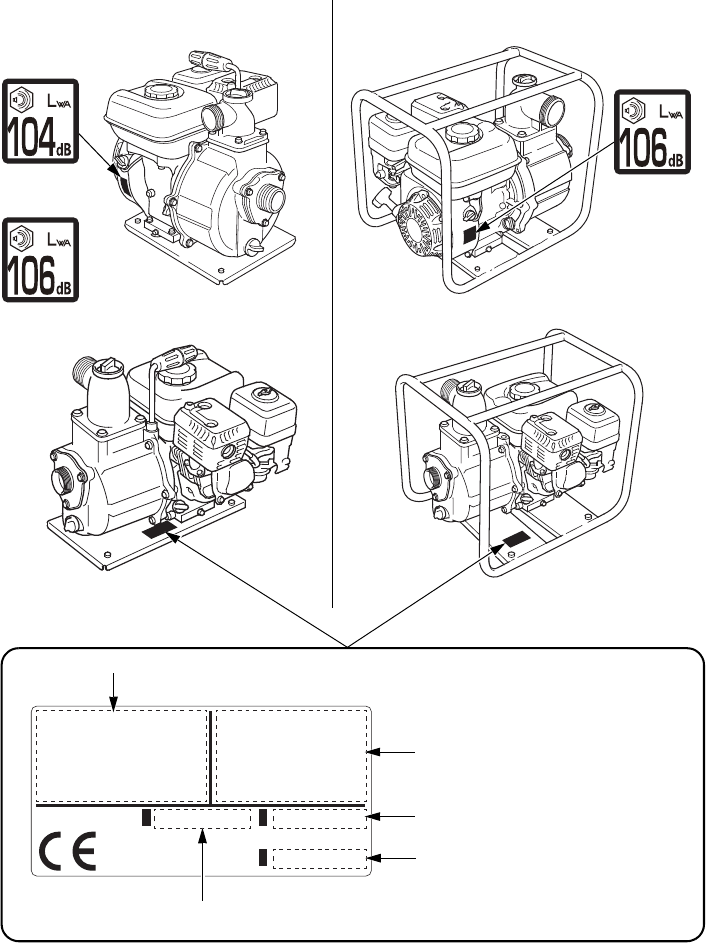

CE MARK & NOISE LABEL LOCATIONS ....................................... 10

CONTROLS & FEATURES ........................................................... 11

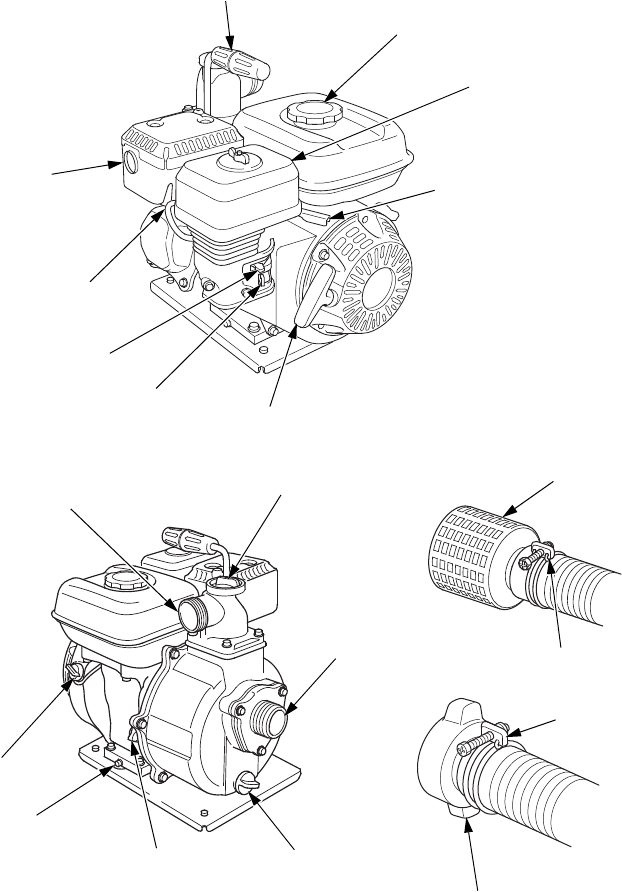

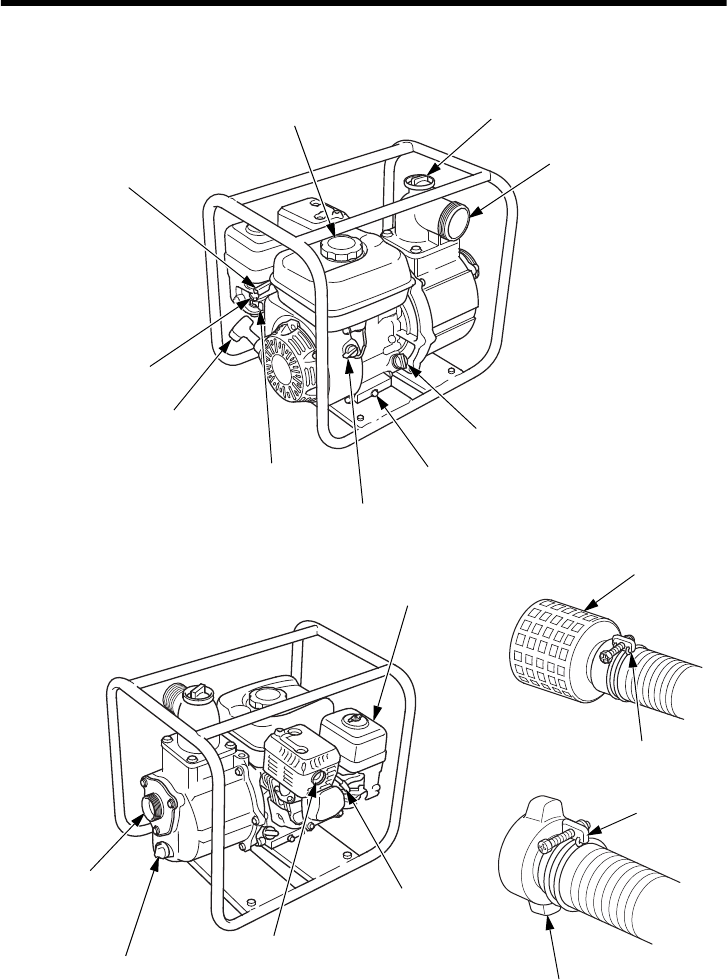

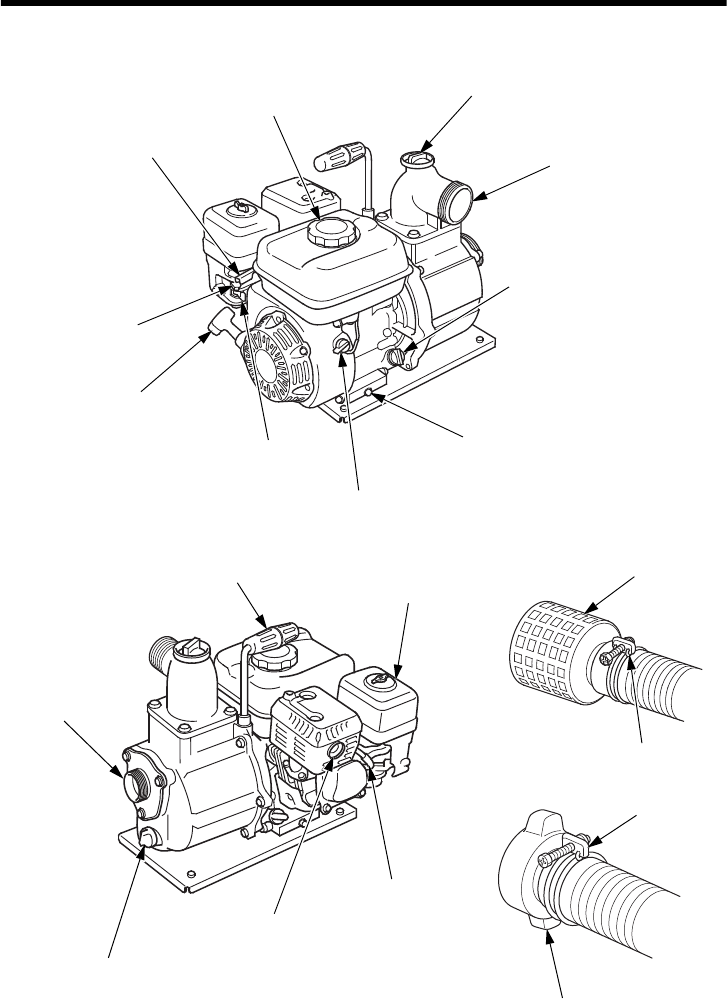

COMPONENT & CONTROL LOCATIONS.................................... 11

CONTROLS ........................................................................... 14

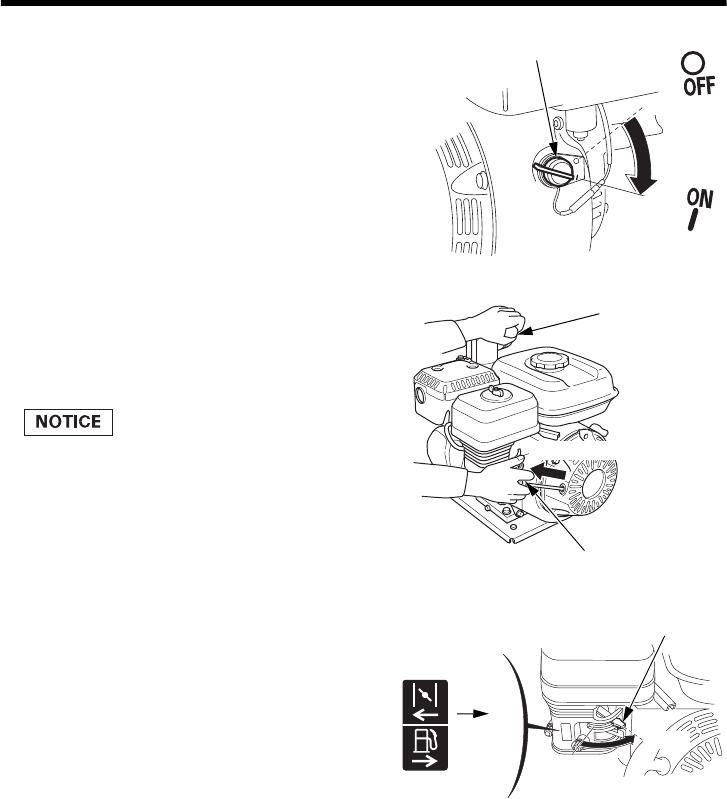

Fuel Valve Lever ................................................................. 14

Ignition Switch.................................................................... 14

Choke Lever ....................................................................... 14

Throttle Lever ..................................................................... 15

Recoil Starter Grip ............................................................... 15

FEATURES ............................................................................ 16

Oil Alert System.................................................................. 16

BEFORE OPERATION ................................................................. 17

ARE YOU READY TO GET STARTED?....................................... 17

IS YOUR PUMP READY TO GO?............................................... 17

Check the General Condition of the Pump .............................. 18

Check the Suction and Discharge Hoses................................. 18

Check the Engine ................................................................ 18

OPERATION.............................................................................. 19

SAFE OPERATING PRECAUTIONS ............................................ 19

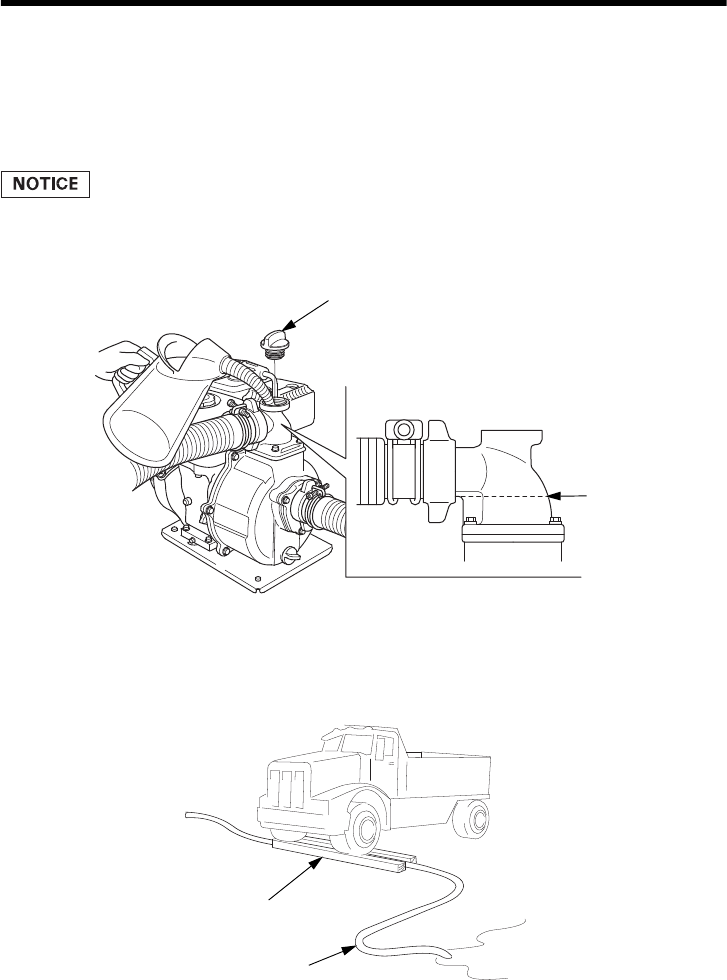

PUMP PLACEMENT ................................................................20

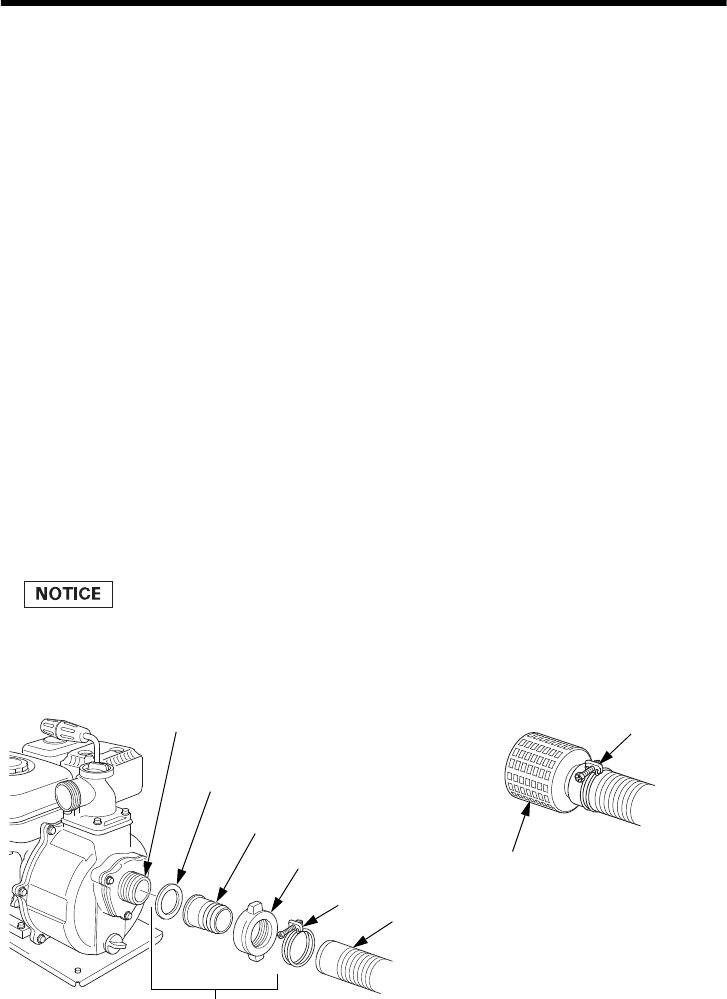

SUCTION HOSE INSTALLATION .............................................. 21

DISCHARGE HOSE INSTALLATION........................................... 22

PRIMING THE PUMP ............................................................... 23

STARTING THE ENGINE .......................................................... 24

SETTING ENGINE SPEED......................................................... 26

STOPPING THE ENGINE .......................................................... 27

SERVICING YOUR PUMP ............................................................ 29

THE IMPORTANCE OF MAINTENANCE ..................................... 29

MAINTENANCE SAFETY ......................................................... 30

MAINTENANCE SCHEDULE ..................................................... 31

REFUELING............................................................................ 32

FUEL RECOMMENDATIONS..................................................... 33

ENGINE OIL LEVEL CHECK ...................................................... 34

36YH6600.book 3 ページ 2015年1月8日 木曜日 午後12時1分