4. Inspect the electrodes and center porcelain

for deposits, erosion or carbon fouling. If the

erosion or deposit is heavy, replace the

plug. Clean a carbon or wetfouled plug with

a plug cleaner, otherwise use a wire brush.

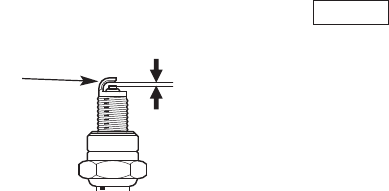

5. Check the spark plug gap (2) using a wire-type

feeler gauge. If adjustment is necessary, bend

the side electrode (3) carefully.

The gap should be:

0.80 - 0.90 mm (0.031 - 0.035 in)

6. Make sure the plug washer is in good

condition.

7. With the plug washer attached, thread the

spark plug in by hand to prevent cross-

threading.

8. Tighten each spark plug:

• If the old plug is good:

1/8 turn after it seats.

• If installing a new plug, tighten it twice to

prevent loosening:

a) First, tighten the plug:

NGK: 1/2 turn after it seats.

DENSO: 3/4 turn after it seats.

b) Then loosen the plug.

c) Next, tighten the plug again:

1/8 turn after it seats.

An improperly tightened spark plug can

damage the engine. If a plug is too loose, a

piston may be damaged. If a plug is too tight,

the threads may be damaged.

9. Reinstall the spark plug caps. Take care

to avoid pinching any cables or wires.

10. Install the remaining parts in the reverse

order of removal.

(2) Spark plug gap

(3) Side electrode

(2)

(3)

106

NOTICE