INSERTING AND REMOVING ACCESSORIES

- Remove battery and set direction switch in middle

(lock) position.

- Put the accessory into the chuck (3) as far as it will go,

then tighten firmly anticlockwise by hand only – hold

one section of the chuck and turn the other to tighten.

- Remove accessories by turning the front part of the

chuck clockwise while holding the other. Keep your

finger off the trigger-switch during these operations.

- Insert battery and unlock direction switch to make

drill ready for use.

Use as a screwdriver

- Remove battery and set direction switch in middle

(lock) position.

- Set sleeve (5) to drill setting then insert a suitable

screwdriver bit into the chuck. Set the torque ring (4)

to desired setting (1 is low and 20 is high). Insert bat-

tery and unlock direction switch to make drill ready for

use.

- Start at low setting and increase setting until the cor-

rect setting for the job is found.

- Use the direction switch set to the right to insert

screws and to the left to remove them.

- Do not use as a screwdriver with the torque

ring set in drill position, this will damage the

drill.

Use as a drill

- Remove battery and set direction switch in middle

(lock) position.

- Set the sleeve (5) to drill setting. Insert a drill bit into

chuck and set the torque ring (4) to drilling position.

- Check the direction switch is set to the correct

direction, normally to "R" for right hand operation.

- Insert battery and unlock direction switch to make

drill ready for use

Use as an impact drill

For drilling hard material like stone or concrete.

- Remove battery and set direction switch in middle

(lock) position.

- Set the sleeve (5) to impact/hammer setting. Insert a

suitable hard tipped masonry bit into chuck.

- Check the direction switch is set to the correct

direction, normally to "R" for right hand operation.

- Insert battery and unlock direction switch to make

drill ready for use.

MAINTENCE, CARE AND

REPAIR

CLEANING

Clean by brushing with a soft brush

Do not use flammable liquids to clean the drill – never use

solvents such as petrol, ammonia or alcohol; they

damage the plastic parts and present a fire risk.

FAULTS

Switch OFF immediately at the mains plug and

remove the plug when:

- The plug or cable is damaged.

- The charger is not operating as it should.

- You smell or see smoke caused by scorched insula-

tion in the machine or charger.

Overheating

The ventilation slots are blocked with dirt. Clean with

dry cloth.

The machine does not start when switched on

- Change the battery for a fully charged one.

- Check that the battery charger is working, if the char-

ging light does not come on; change the fuse in the

plug.

- Take to your Ferm Dealer for repair.

The motor is defective

Take to your Ferm Dealer.

MAINTAIN TOOLS WITH CARE

Keep the tool clean for better and safer performance.

Store the accessories properly in accordance with the

maker’s instructions.

Follow instructions for changing accessories. Inspect

tool and extension cables periodically and if damaged,

have them repaired by a qualified person or authorised

service body. Keep handles free from oil or grease. Keep

the ventilation slots clean to prevent motor overheating.

Check for damaged parts

Do not use a tool with damaged parts, before further use

a damaged tool must be carefully checked by a qualified

person to determine that it will operate properly. Check

for alignment of moving parts, binding or breakage of

parts, mounting and other conditions that may affect its

operation. A damaged part or guard should be properly

repaired by an authorised service centre, unless indica-

ted otherwise in the instruction manual. Have defective

switches replaced by an authorised service centre. Do

not use a tool if the switch does not turn on and off. For

advice please contact the help line.

Have your tool repaired by an expert

This appliance is manufactured in accordance with rele-

vant safety standards. Only experts must carry out repai-

ring of electrical appliances, otherwise considerable dan-

ger for the user may result.

Storing tools

When not in use tools should be stored in the dry, out of

reach of children.

Ferm 5

USING THE COMBI DRILL

BEFORE OPERATING

- Check that the voltage marked on the charger is sui-

table for use with your mains supply.

- The output voltage on the charger is suitable to use

with the drill battery.

- The battery voltage is suitable for the drill.

Note: The battery supplied with the drill is not fully

charged.

CHARGING THE BATTERY

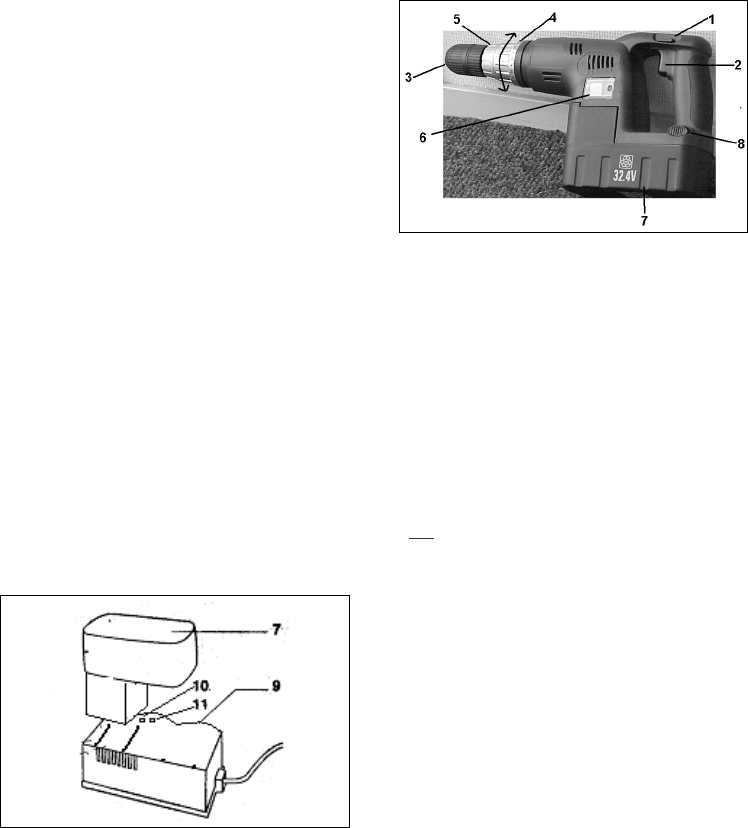

Refer to Fig. A.

- Place the battery charger (9) on a level surface, check

it is connected correctly and the air vents on the

charger are not blocked, then slide the battery (7)

onto the charger. Make sure the terminals on the bat-

tery tongue line up with the + and – terminals on the

charger. The red light (10) on the charger indicates

the battery is being fast charged. When charging is

finished the red light will go out and the green light

(11) will light, indicating that the battery is ready for

use

- The first charge will take 2-3 hours; the battery will

reach maximum performance after it has been char-

ged 4-5 times. (Normal charge time is approximately

2 hours.)

- Only use the charger between +100 and +40° C in

dry conditions.

- Do not fully discharge the battery, in use. The battery

should be re-charged when significant loss of power

is incurred.

Fig. A

INSERTING & REMOVING THE BATTERY

FROM THE DRILL

Refer to Fig. B.

- Make sure the direction switch (1) is in the middle

(lock) position so that the drill does not start unexpec-

tedly. Slide the battery (7) onto the terminals on the

underside of the drill; it can only go in one way and will

click when in place. To remove battery, push the tabs (8)

on either side of the drill handle with finger and thumb

and slide out of drill.

Fig. B

OPERATION

To switch ON/OFF

Make sure the direction switch (1) is set to left or right

position, then press the trigger switch (2)

To lock trigger

Release the trigger switch and put the direction switch

(1) in the central position

Speed control

Adjust the drills speed by more or less pressure on the

trigger-switch (2).

Direction of rotation

Change the direction of rotation by setting the direction

switch (1) to left or right, this must be done when the drill

is not

rotating.

Drill or impact setting

Set sleeve (5 clockwise to "drill" position and anticlock-

wise to "impact or hammer setting"

4 Ferm