26 Ferm Ferm 3

grip.

•

Tighten the workpiece to a workbench by using a clamp.

•When all preparations are done the machine can be

connected to mains. First check if the switch is in the

‘OFF’-position and if the rotationswitch is in the

RIGHT-position.

3. OPERATION

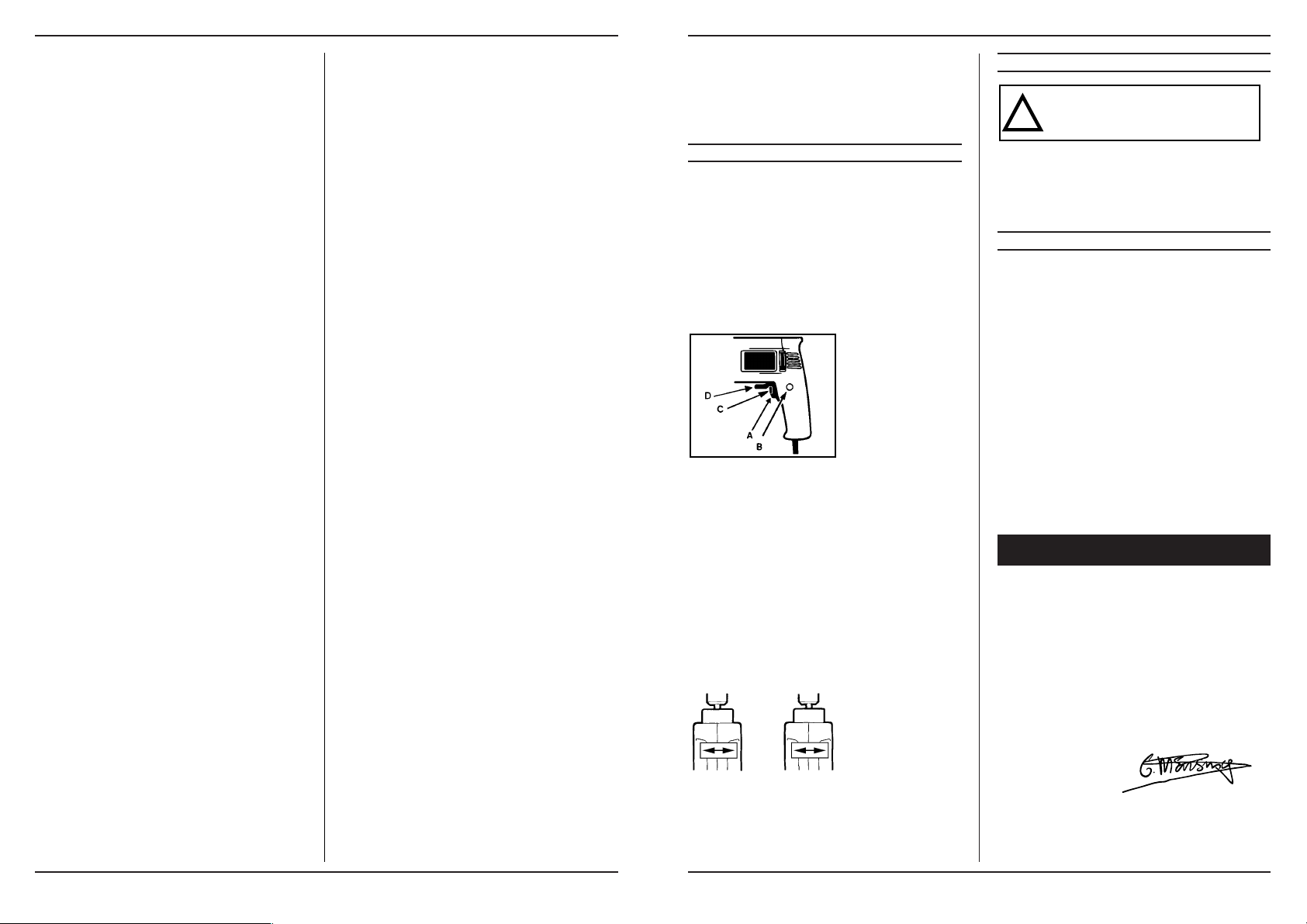

1. THE ON/OFF SWITCH

Switch the machine on by pressing the triggerswitch (A).

When you release the triggerswitch (A) the machine will

turn off.

2. SWITCH-LOCK

You can lock the On/Off switch by pressing the triggers-

witch (A) and then pressing knob (B). Release the switch-

lock by pressing the triggerswitch (A) shortly.

3. SPEED-CONTROL

The rotation-speed can be

continuously adjusted be-

tween 0 and 2500 rota-

tions per minute, by pres-

sing the switch (A) deeper

or less deep.

4. ADJUSTING OF THE MAXIMUM ROTA-

TIONSPEED

-

Switch the machine on by pressing triggerswitch (A);

-Lock the triggerswitch (A) by pressing knob (B);

-Adjust the speed by turning the small wheel (C) to the

desired maximum rotation speed.

5. SWITCHING THE DIRECTION OF ROTA-

TION

-Direction of rotation counter-clockwise: shift switch

(D) to “L”;

-Direction of rotation clockwise: shift switch (D) to

“R”.

6. SWITCH FOR PERCUSSION DRILLING

With the switch on top

of the machine you can

select normal or percus-

sion drilling.

-Slide the switch to

the “Drill” symbol

for normal drilling;

-Slide the switch to the “Hammer” symbol for per-

cussion drilling.

4. MAINTENANCE

While maintaining and cleaning the machine

pull the plug from the mainssocket. Never use

water or other agressive liquids while cleaning

electrical parts of the lamp.

-Keep the mains cord of the machine clean, some fluids

contain solvents can dissolve plastic parts of the ma-

chine.

-Keep the ventilation slots of the machine clean to pre-

vent overheating of the motor.

5. MALFUNCTION

Below we have listed a number of possible causes and

corresponding solutions in case the machine does not

function as it should:

1. Excessive sparkling.

This usely indicates dirt in the motor or worndown

carbon brushes.

-Bring your percussion drill to your Ferm-dealer.

2. The percussion drill is overheating.

The ventilationslots are covered with dirt.

-Clean them with a dry cloth.

The percussion drill is overloaded.

-Use the machine for work for which it is ment to be.

-Replace the drill for a sharp one or sharpen the drill by

using a benchgrinder and a Twist drill grinding attach-

ment.

The motor is defect.

-Bring your percussion drill to your Ferm-dealer for re-

pairance.

ClEl

■

DECLARATION OF CONFORMITY (GB)

We declare under our sole responsability that this

product is in conformity with the following

standards or standardized documents

EN50144-2-1, EN50144-1

EN55014-1, EN61000-3-2, EN61000-3-3, EN55014-2

in accordance with the regulations:

98/37/EEC

73/23EEC

89/336/EEC

from 01-06-2000

GENEMUIDEN NL

G.M. Ensing

Quality department