GB

BENCH LATHE MACHINE

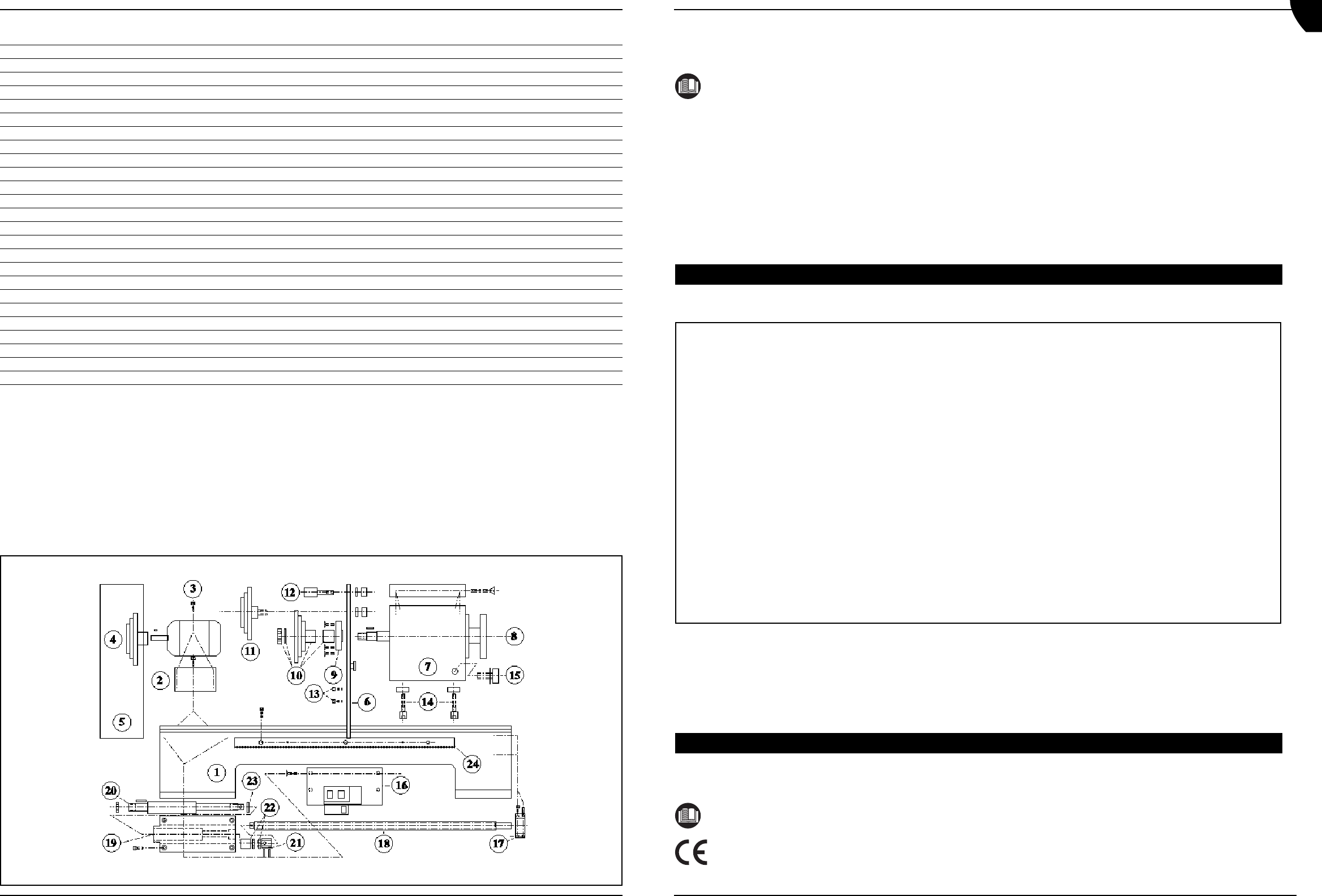

The numbers in the following text correspond with the pictures at page 2 – 4.

Carefully read this manual before using the machine. Make sure that you know how the machine functions and how to operate it.

Maintain the machine in accordance with the instructions to make sure it functions properly. Keep this manual and the enclosed

documentation with the machine.

Use

The metal lathe has been designed for processing, mechanically removing metal, of ferrous and non-ferrous metals, synthetics and wood.

The metal lathe is meant for semi-professional use and for leisure interests.

Contents

1. Machine data

2. Safety instructions

3. Installation

4. Before operation

5. Operation

6. Maintenance

1. MACHINE DATA

Technical specifications

The machine is delivered in the following base performance

Machinebed with prism conductor, ferme head with main shaft and drive for automatic longitudinal feed and thread cutting, tail stock with

sliding tube and transverse adjustment, electro motor with start/stop- and sense of rotation switch, support with lock case, combined with

starting/lead screw, cross slide with rotating plate and tool slide, fourfold tool holder with index pin, 3-chuck with extra exterior basins and

measuring certificate, drive protection case, 7 change wheels, 3 driving-belts, 2 centers, 3 open-end spanners, 2 socket head wrenches,

catch pin and a tightening-wrench chuck.

Excluded under-carriage (Art.No. BLA1009).

2. SAFETY INSTRUCTIONS

Explanation of symbols

The following symbols are used in these instructions for use:

Read instructions carefully

In accordance with essential applicable safety standards of European directives

Mains voltage 230 Volt

Mains frequency 50 Hz

Absorbed power 370 Watt

Center height 110 mm

Center distance 500 mm

Max. turndiameter above bed 200 mm

Max. turndiameter above support 115 mm

Culvert and recording main shaft 18 mm, MT-3

Number of speeds main shaft 6

No load speeds main shaft 120 - 2000/min

Automatic start 11 mm, 0.04 - 0,3

Thread cutting (right) 11 mm, M0.4 - M3

Distance toolholder centerline measured vertically 15 mm

Rotating plate movement 360º

Graduation rotating plate ± 45º

Movement tool cut 70 mm

Movement cross slide 115 mm

Movement end slide 500 mm

Graduation slide screws 0.04 mm

Recording and stroke slide tube MT-2, 50 mm

Graduation slide tube 0.05 mm

Weight 115 kg

Sound pressure Lwa 70.0 dB(A)

Vibration value 2.8 m/s

2

Ferm 05

100 Ferm

D

NL

F

E

P

I

RUS

GR

Annex 4 - Parts list bed/headstock

No. Part

1 Bed

2 Motor base plate

3 Motor

4 Motor pulley

5 Guard

6 Mounting plate

7 Headstock with cover

8 Mains spindle

9 Bearing cover

10 Main spindle pulley

11 Idler

12 Tension pulley

13 Bolts with ring

14 Chuck headstock

15 Oil cup

16 Switch

17 Longitudinal and traerse motion bearing

18 Longitudinal traverse (lathe spindle

19 Bearing housing drive shaft

20 Drive shaft longitudinal and transverse motion

21 Bush

22 Castle locking nuts

23 Axial thrust bearing

24 Gear rack

4