2

TABLE OF CONTENTS

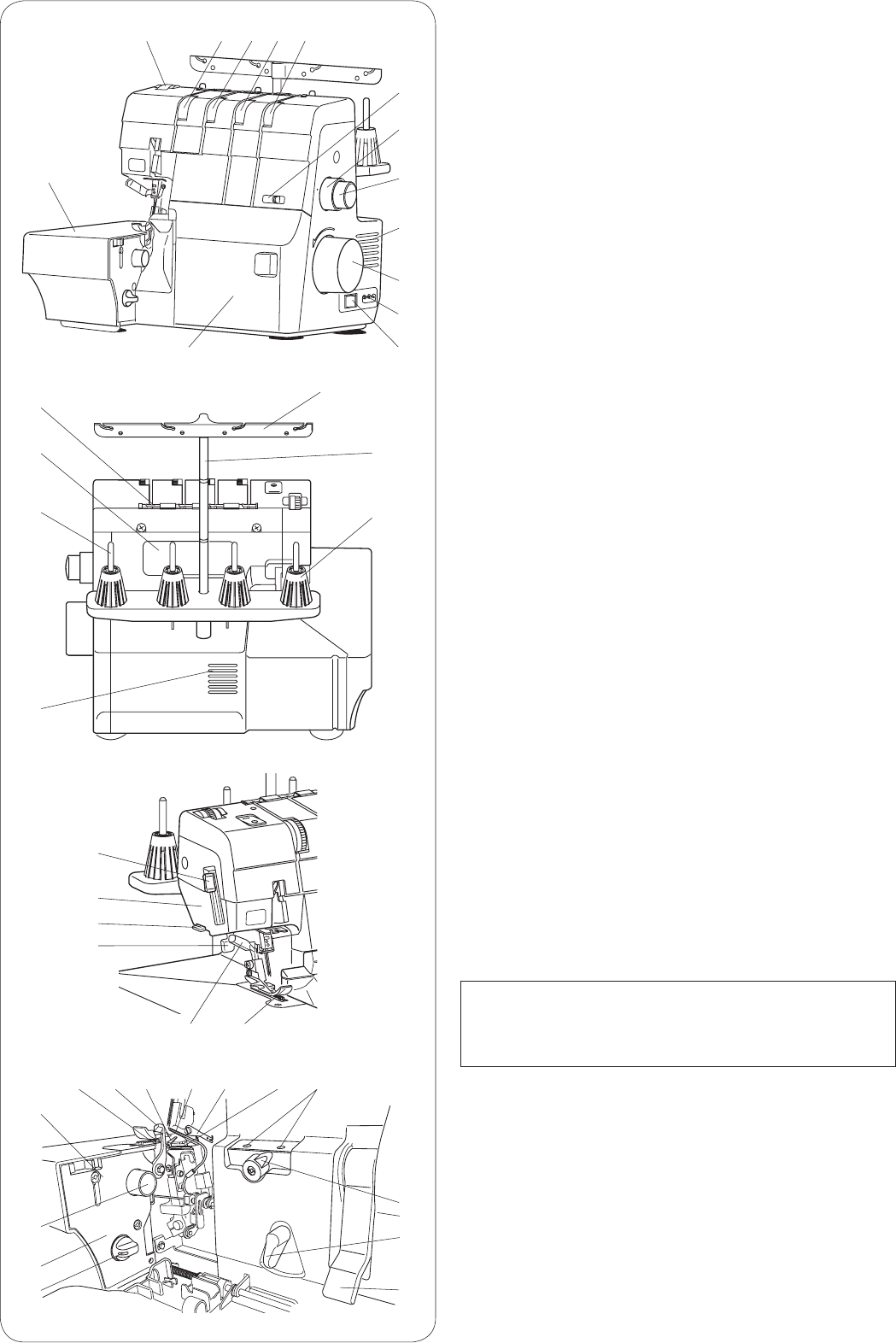

ESSENTIAL PARTS

Names of Parts ............................................................... 3

Safety Device ................................................................. 4

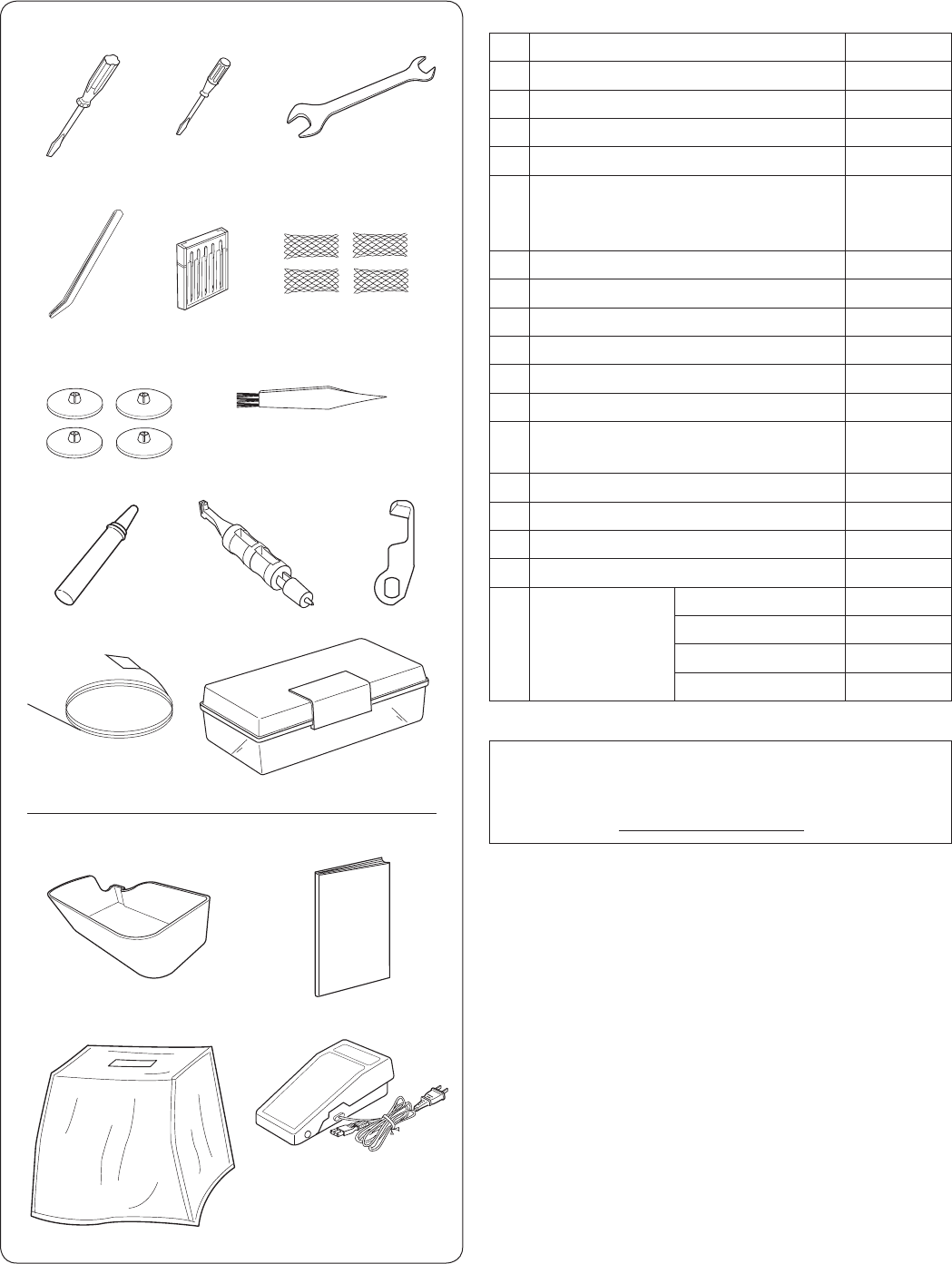

Standard Accessories .................................................... 5

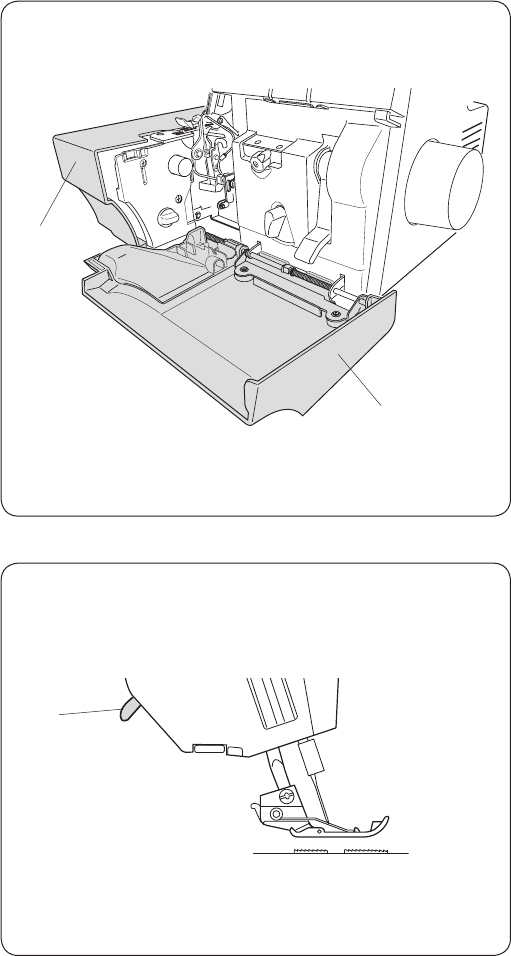

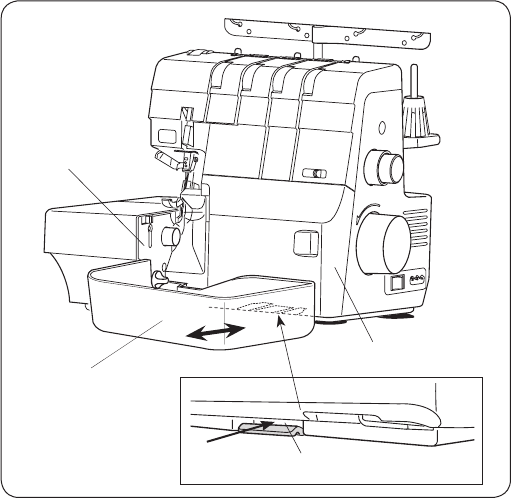

Waste Chip Box .............................................................. 6

GETTING READY TO SEW

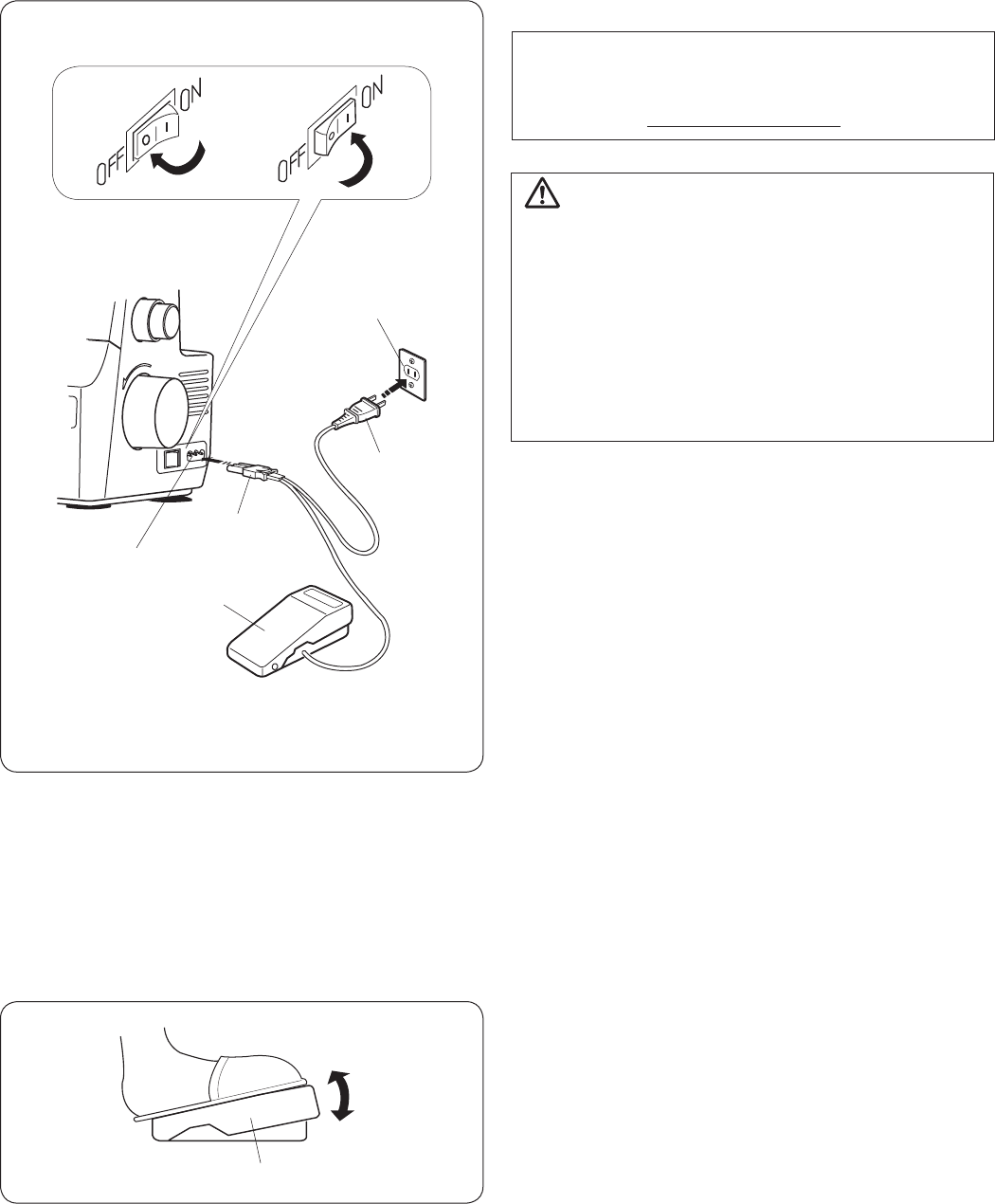

Connecting the Power Supply ........................................ 7

Before Using Your Machine ............................................ 7

Operating Instructions: ................................................... 7

Controlling Sewing Speed .............................................. 7

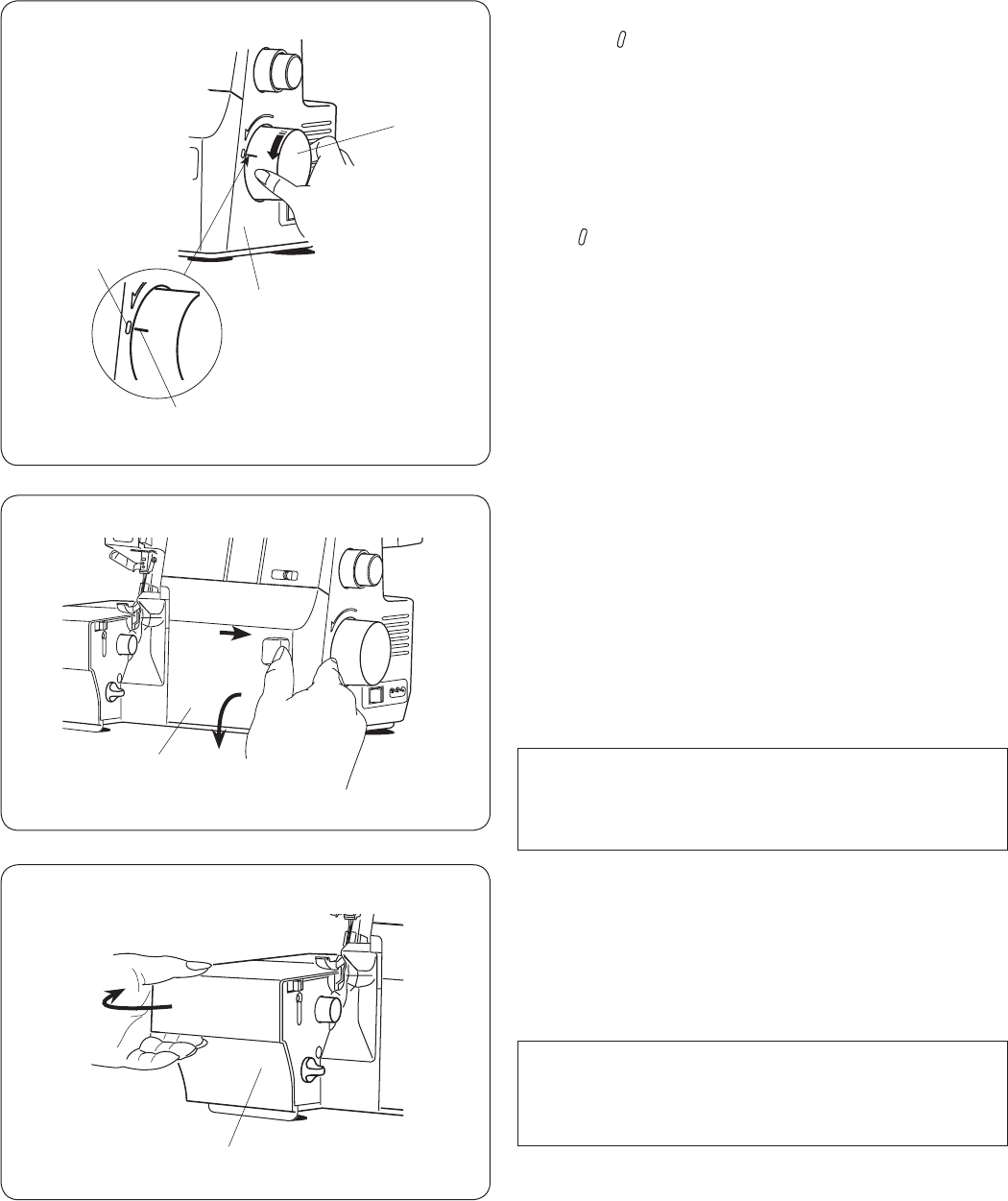

Handwheel ..................................................................... 8

Looper Cover .................................................................. 8

Side Cover ...................................................................... 8

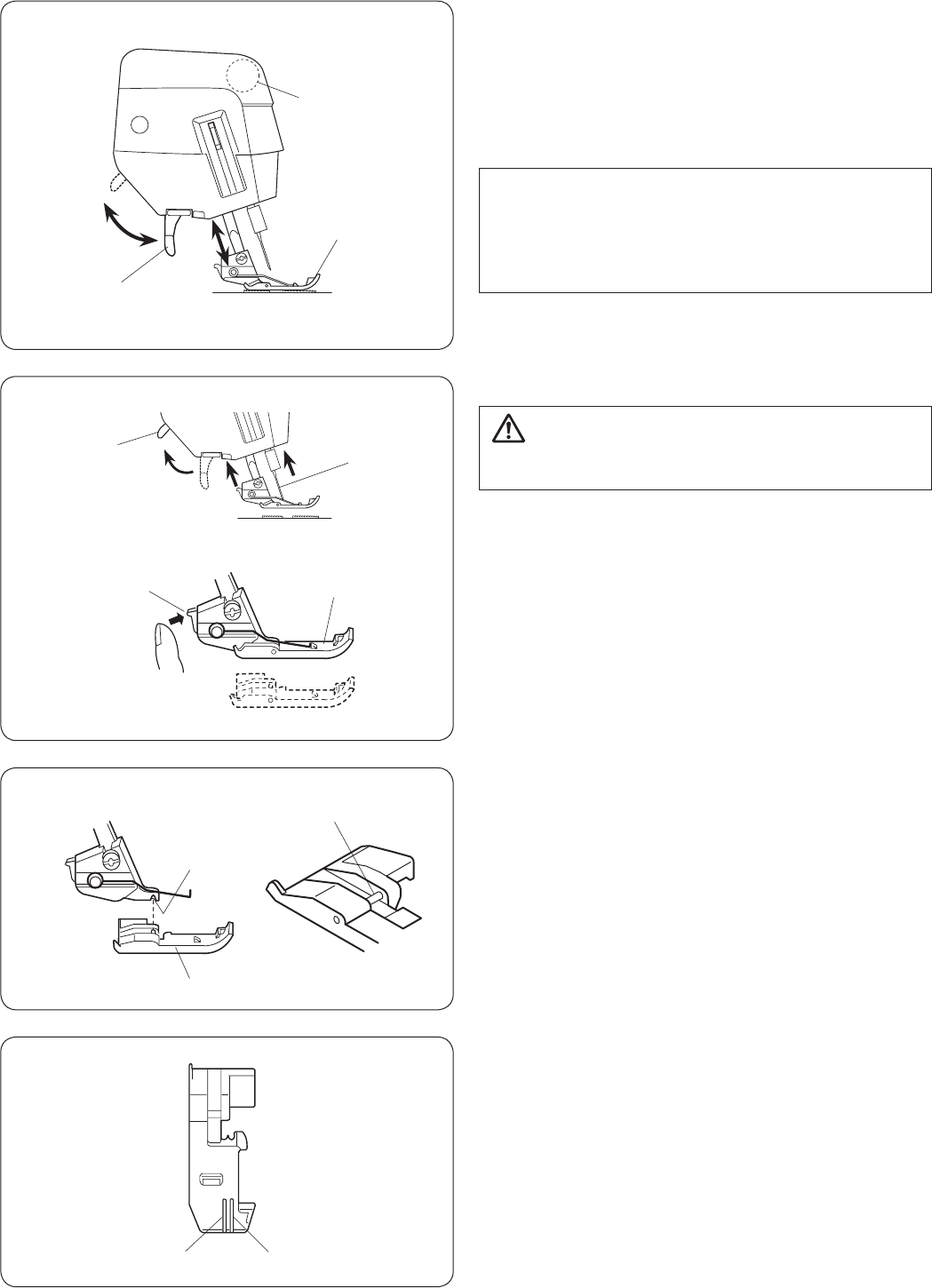

Presser Foot Lifter .......................................................... 9

Removing or Attaching the Presser Foot ....................... 9

Presser Foot Guide Lines ............................................... 9

Presser Foot Pressure Dial .......................................... 10

Changing the Needle.................................................... 10

Checking the needle .................................................. 10

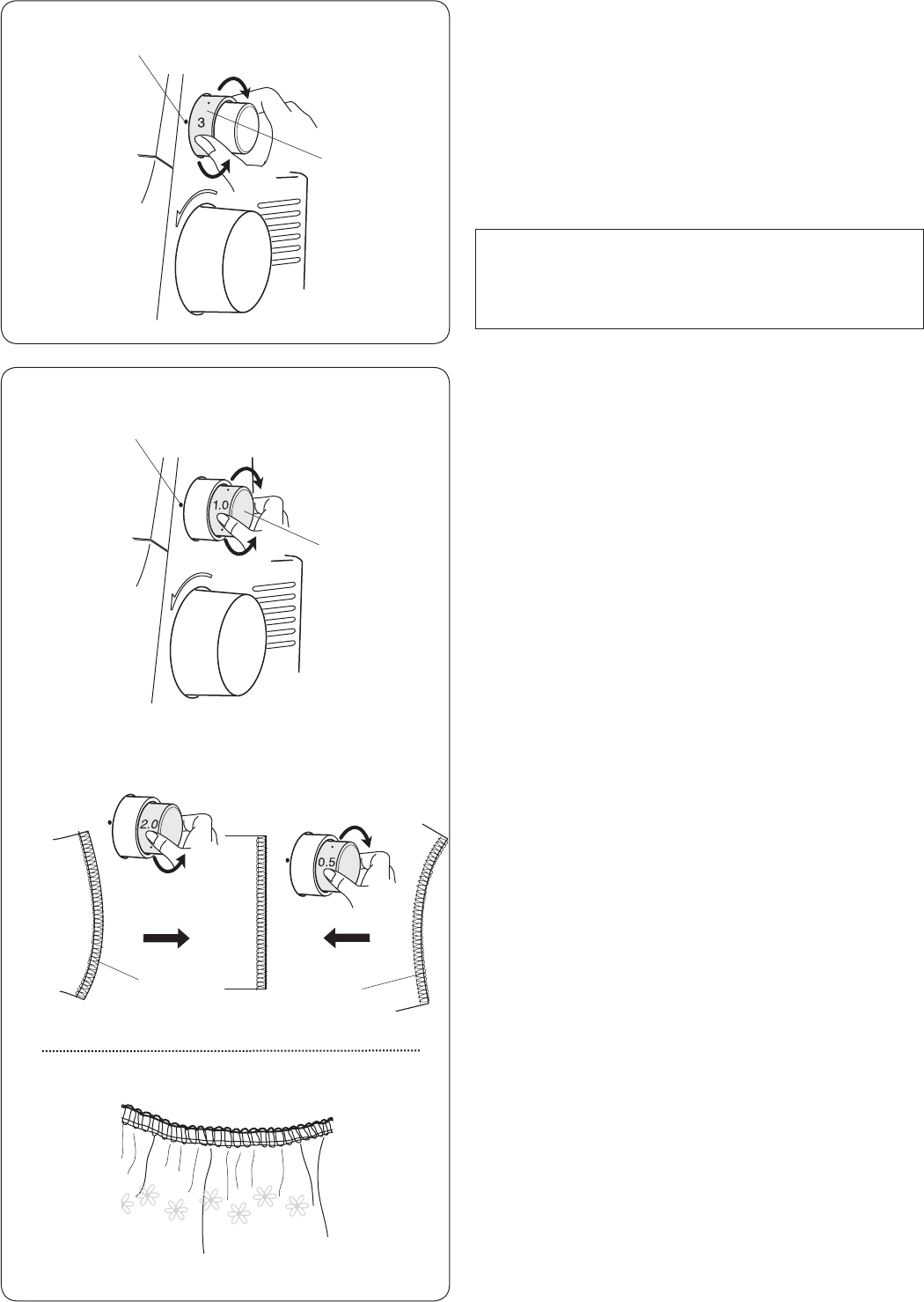

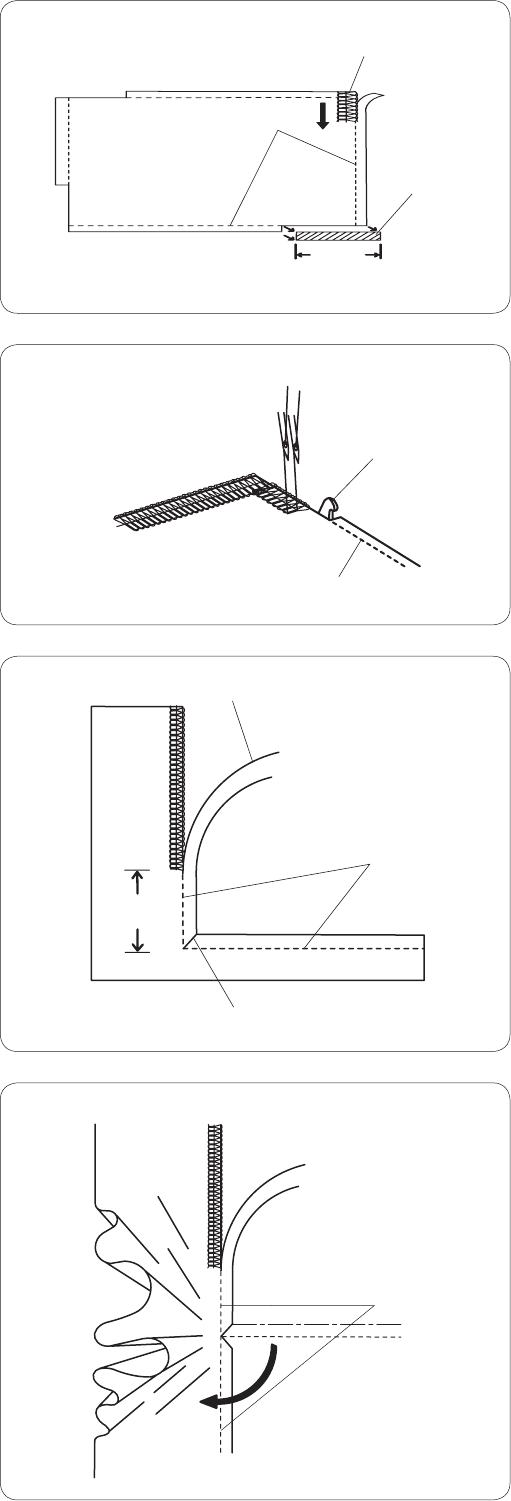

Stitch Length Adjustment ..............................................11

Differential Feed Ratio Adjustment ..............................11

How to adjust ...............................................................11

Gathering .....................................................................11

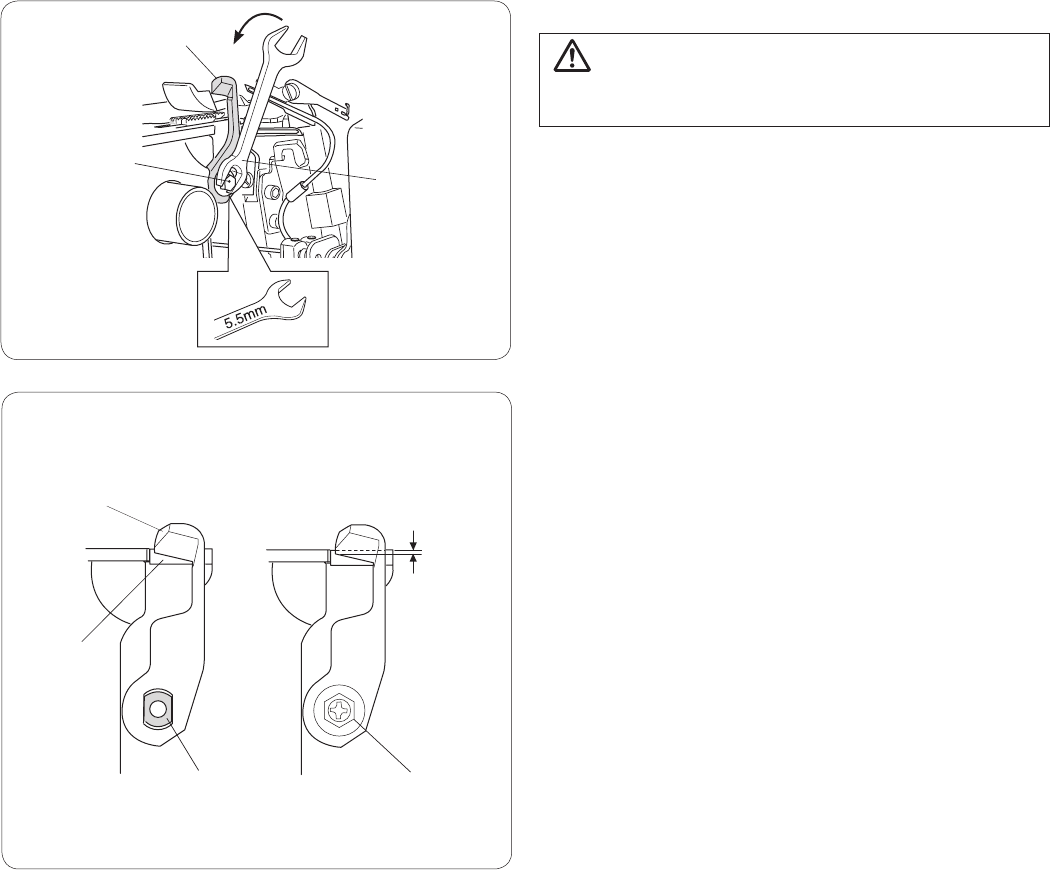

To Deactivate or Activate the Upper Knife ................... 12

Cutting Width Adjustment ............................................. 12

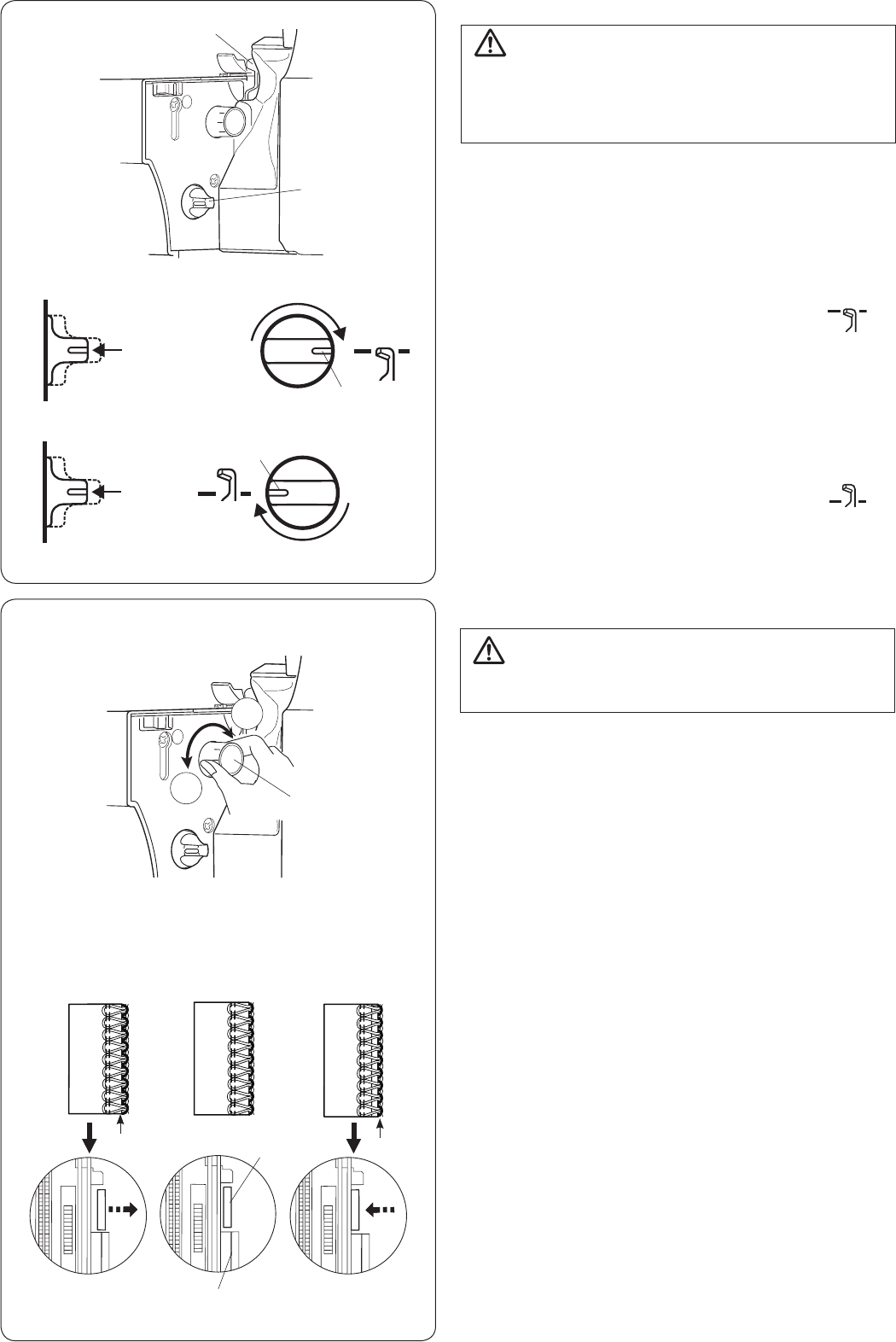

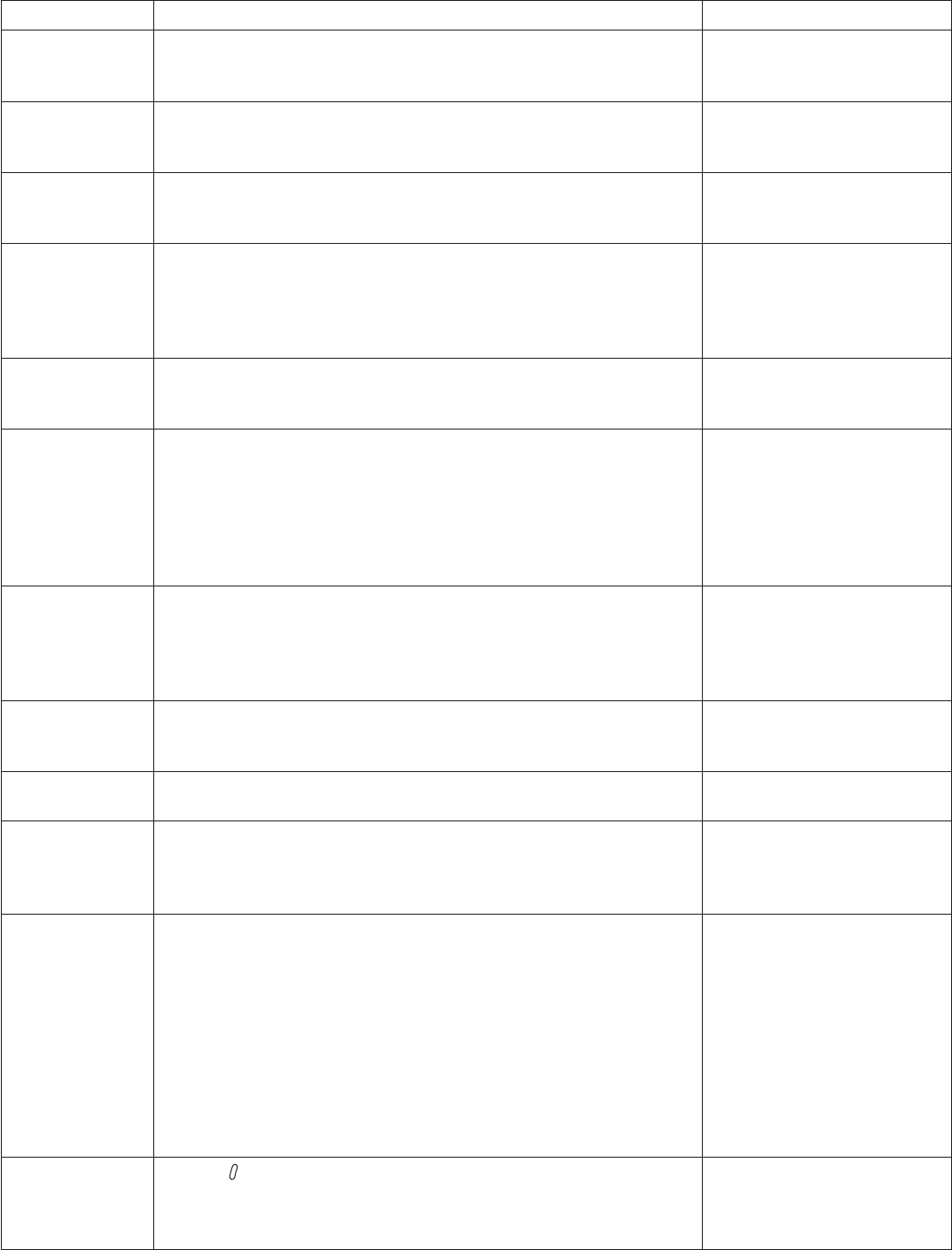

Chaining Finger Switch Knob Adjustment (Changing to

Standard Serging or Rolled Hemming) ........................ 13

Standard serging ........................................................ 13

Rolled hemming ......................................................... 13

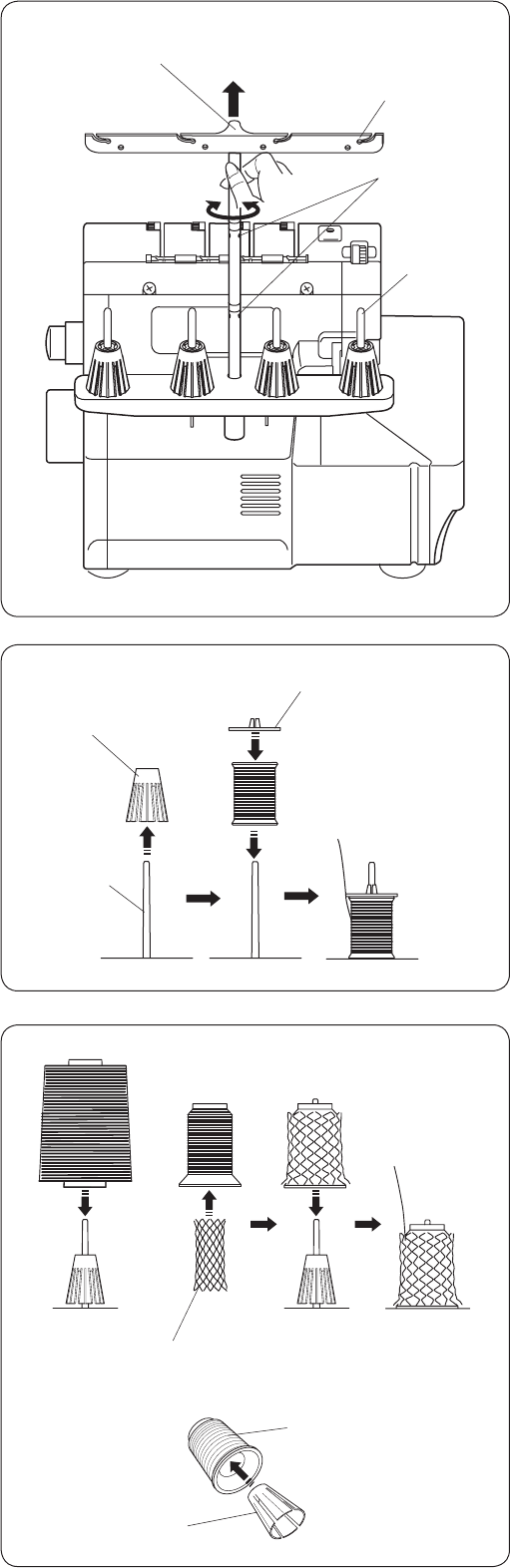

Position of Thread Guide Bar ....................................... 14

Attaching the Spool Holder Cap and Net ..................... 14

MACHINE THREADING

Threading the Machine (4 threads) .............................. 15

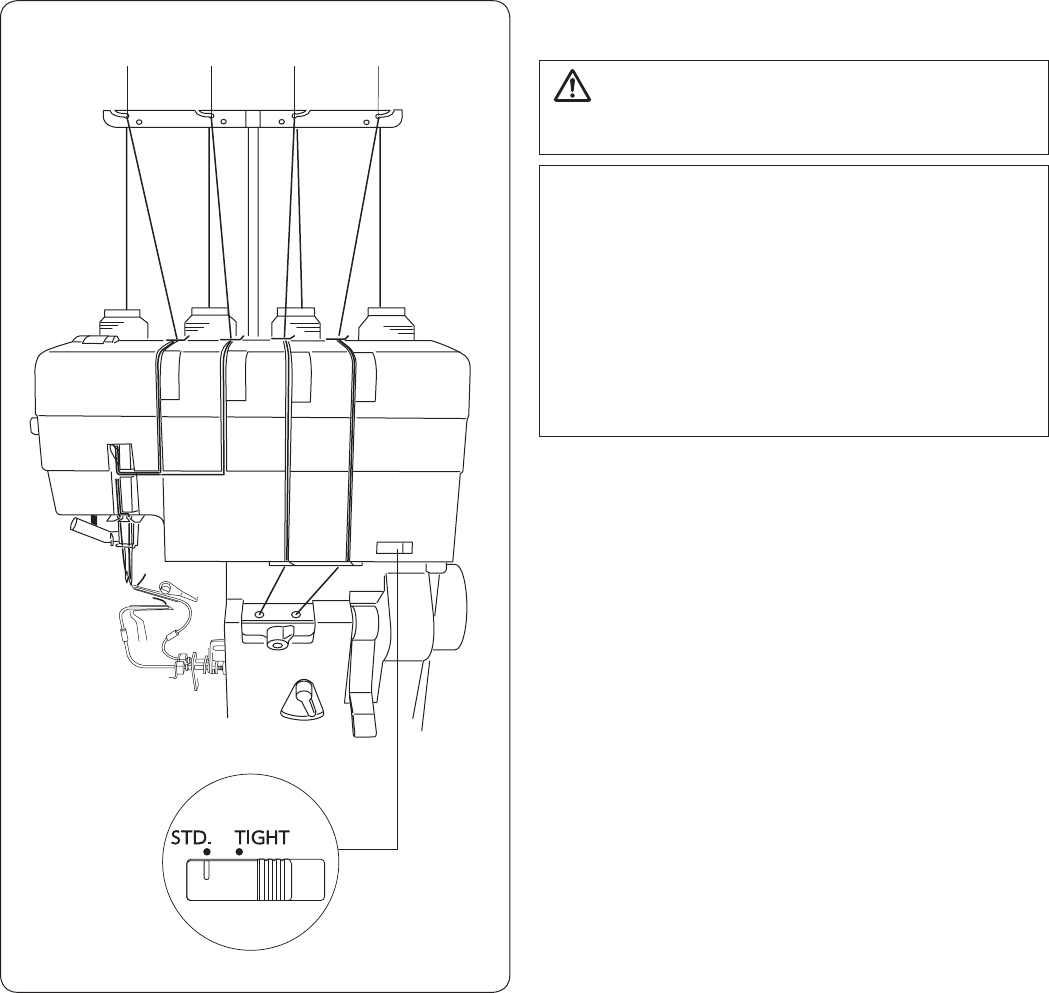

Preparation ................................................................. 15

Lower looper pre-tension setting slider ...................... 15

Threading the Machine (3 threads) .............................. 16

Threading the Machine (2 threads) .............................. 17

Using the Spreader for Two-thread Serging ................. 18

Raising the spreader .................................................. 18

Lowering the spreader ................................................ 18

Threading the Lower Looper ................................... 19-21

Threading the Upper Looper ................................... 22-25

Adjusting the looper threader switch lever ................... 23

Threading Loopers with the Looper Threading Wire or

Standard Thread .....................................................26-27

Using the looper threading wire ................................. 26

Using a standard thread ............................................. 27

Replacing threaded looper thread .............................. 27

Threading the Right Needle ....................................28-30

Using the needle threader .......................................... 30

Threading the Left Needle ....................................... 31-32

Thread and Needle Chart ............................................. 33

TEST STITCHING

Starting Sewing ............................................................ 34

Finishing Sewing .......................................................... 34

Sewing Continuously .................................................... 35

Using Guide Lines ........................................................ 35

Securing Ends .............................................................. 36

At the beginning of the seam ...................................... 36

At the end of the seam ............................................... 36

Cutting the Seams ........................................................ 36

Thread Tension (4 threads) ..................................... 37-38

Thread Tension (3 threads) .......................................... 39

Thread Tension (2 threads) .......................................... 40

ROLLED HEMMING, PICOT EDGING AND NARROW

HEMMING

Tension Dial and Machine Settings According to the

Thread and Fabric ........................................................ 42

For Better Results ........................................................ 43

Thread Tension........................................................44-45

ADVANCED TECHNIQUES

Decorative Overedging................................................. 46

Gathering ...................................................................... 47

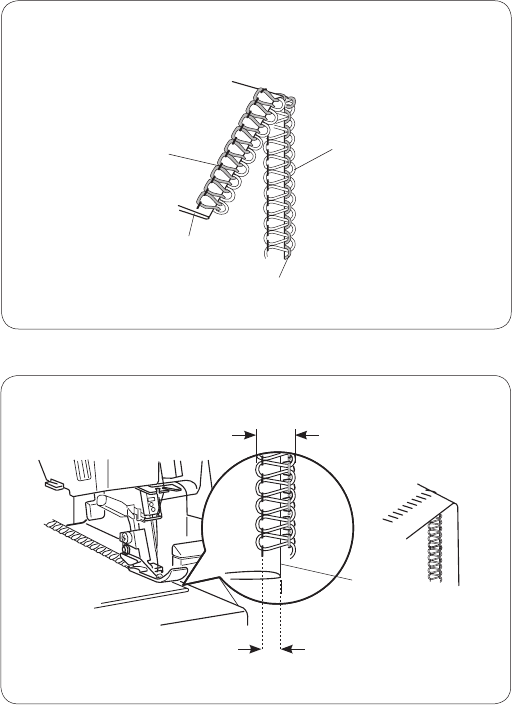

Pintucking ..................................................................... 48

Flatlock ....................................................................49-50

Sewing Corners ............................................................ 51

CARE OF YOUR MACHINE

Cleaning the Upper Knife Area .................................... 52

Cleaning the Feed Dog ................................................ 52

Cleaning the Looper Threader Pipe ............................. 53

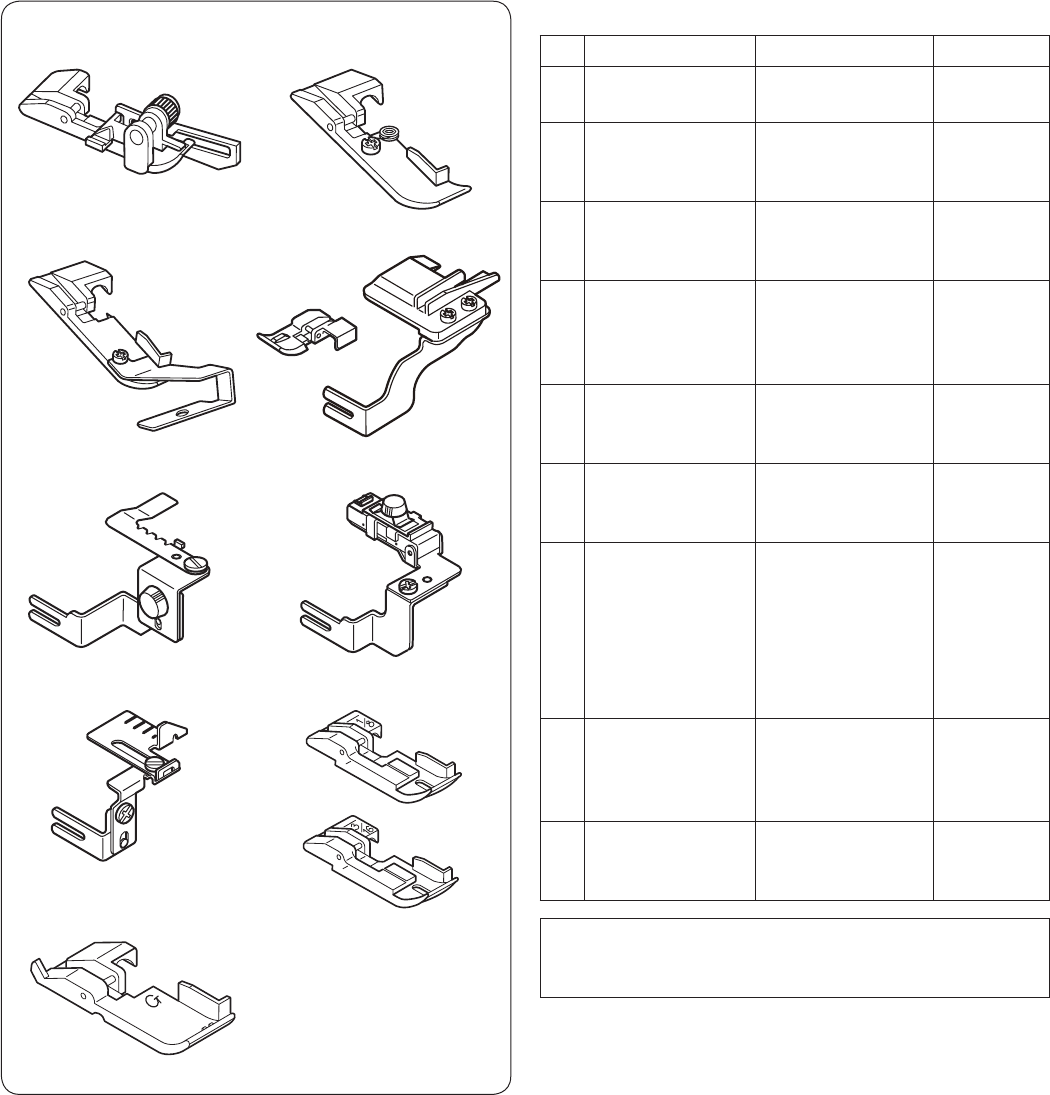

Replacing the Upper Knife ........................................... 54

Oiling the Machine........................................................ 55

Troubleshooting ............................................................ 56

Optional Accessories ................................................... 57

EC DECLARATION OF CONFORMITY ....................... 58