3

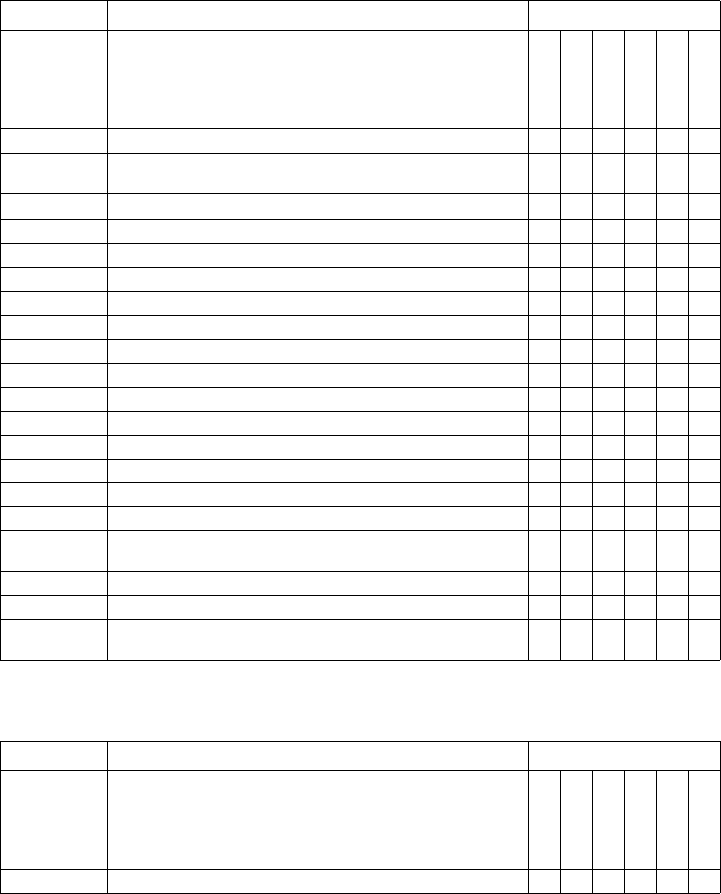

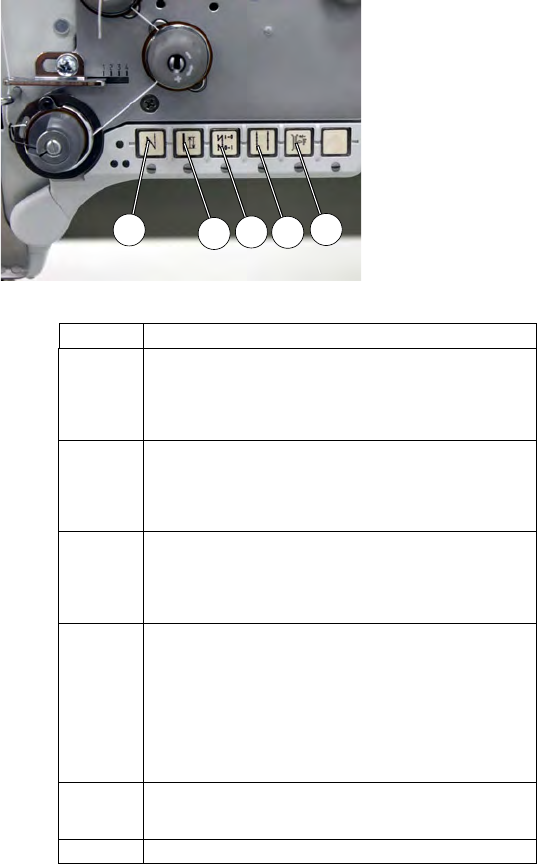

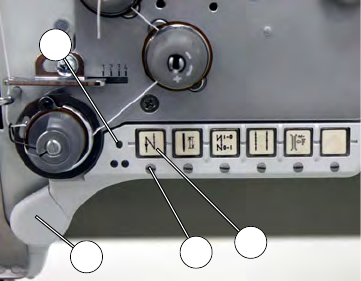

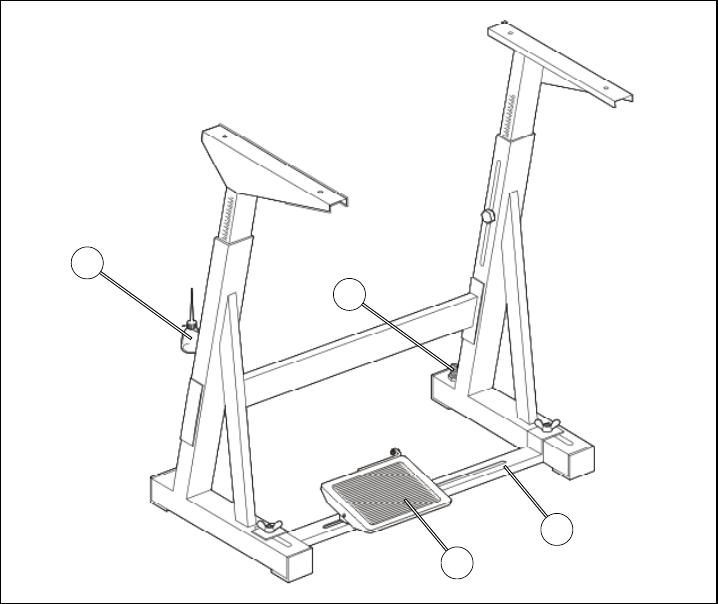

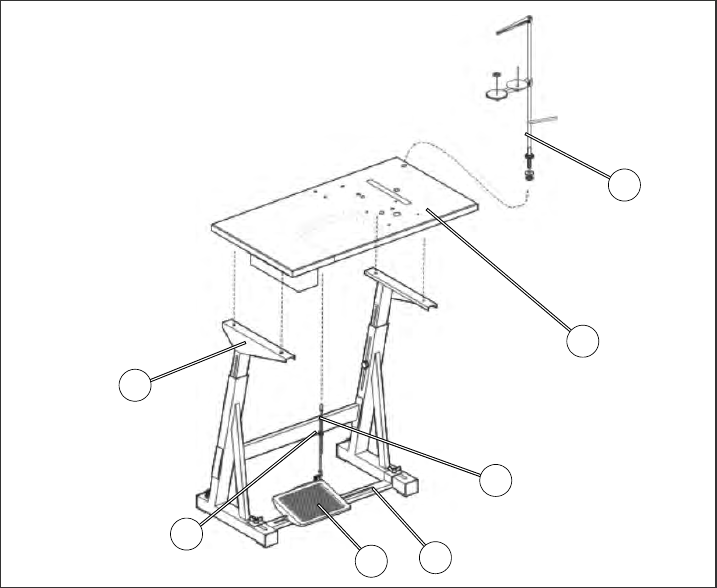

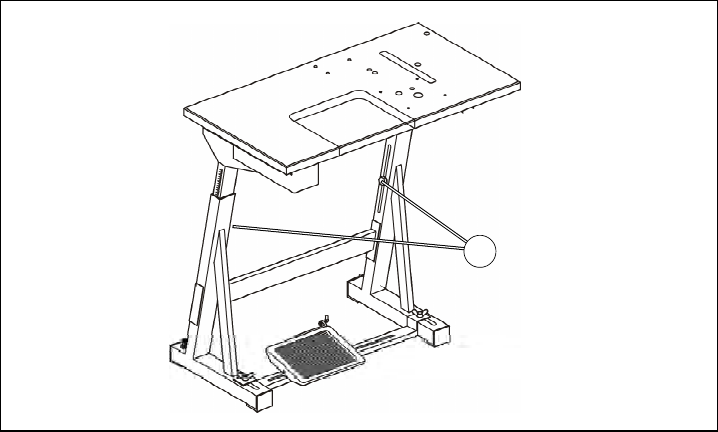

2 Product description

2.1 Product description

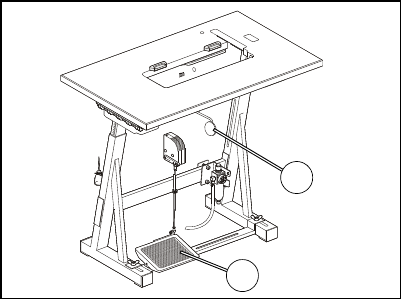

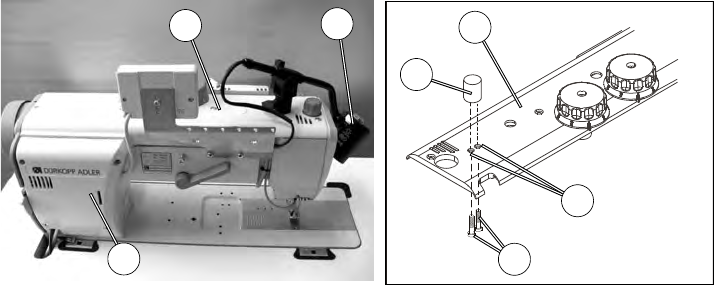

The Dürkopp Adler 667 is a special sewing machine for first-class single-

needle decorative seams in light to medium-heavy material.

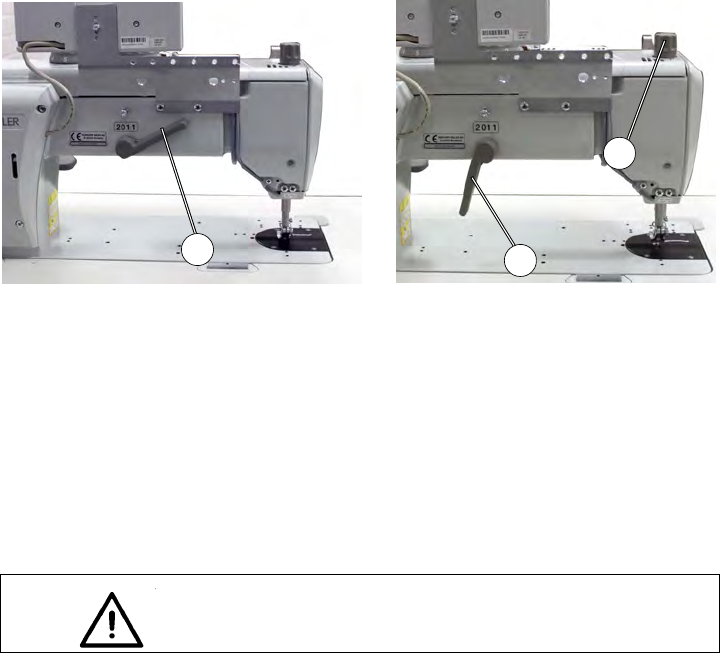

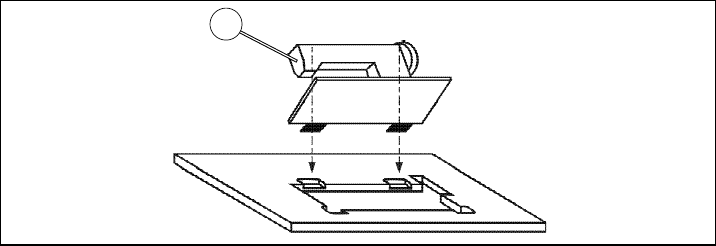

It is a single-needle flatbed double-backstitch machine with lower

conveyor, needle transport and alternating upper foot conveyor.

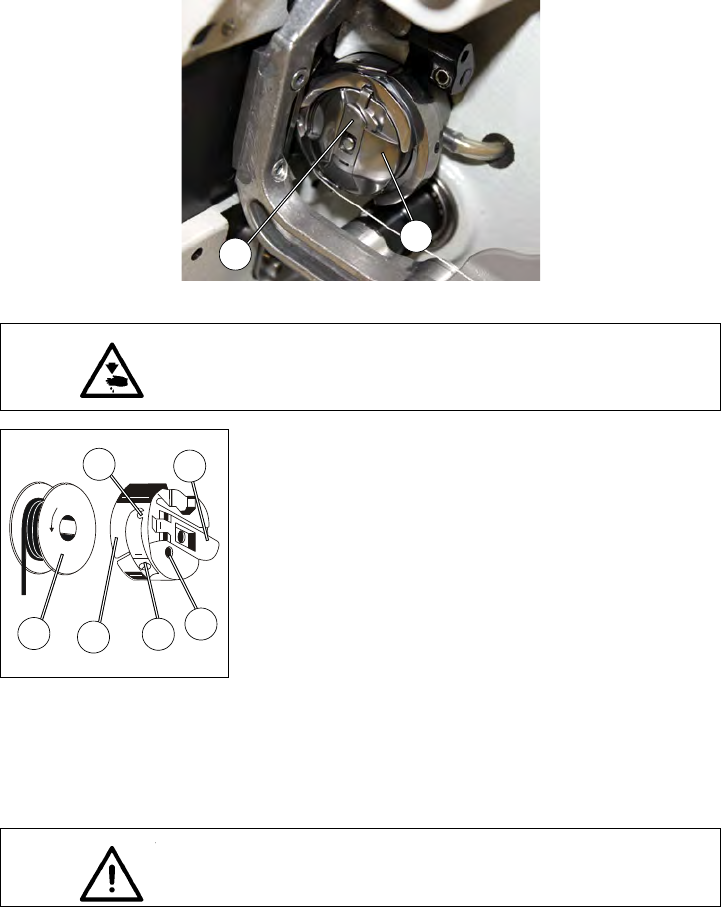

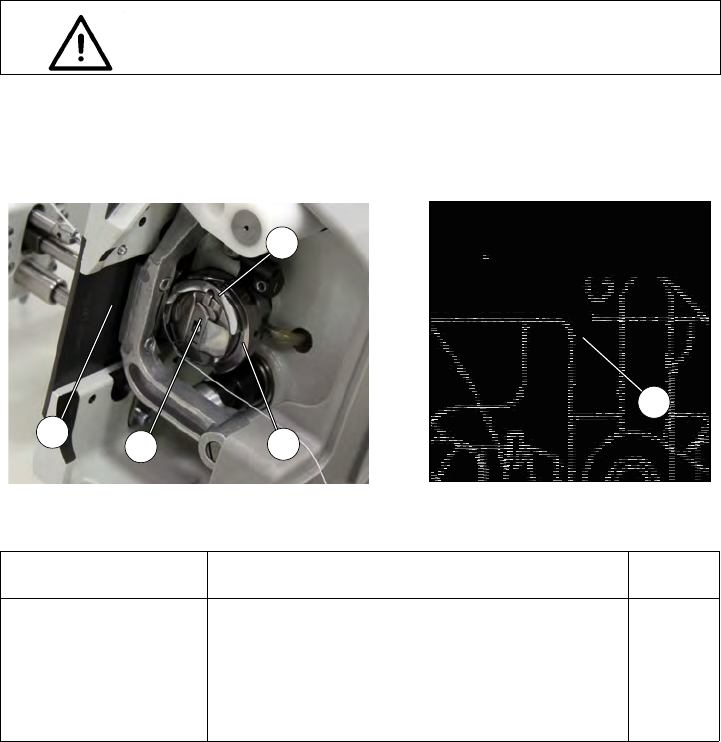

A safety coupling prevents the shuttle from being displaced or damaged

if the thread jams in the shuttle track.

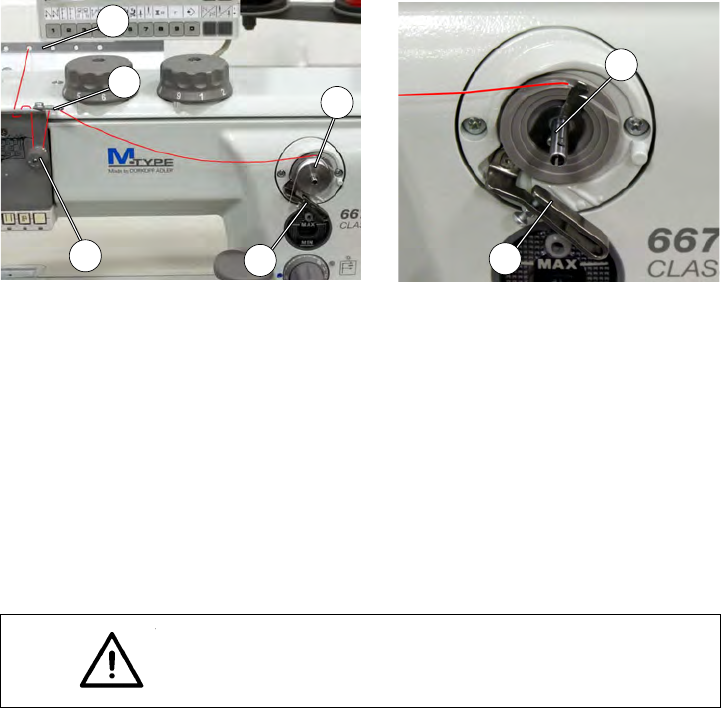

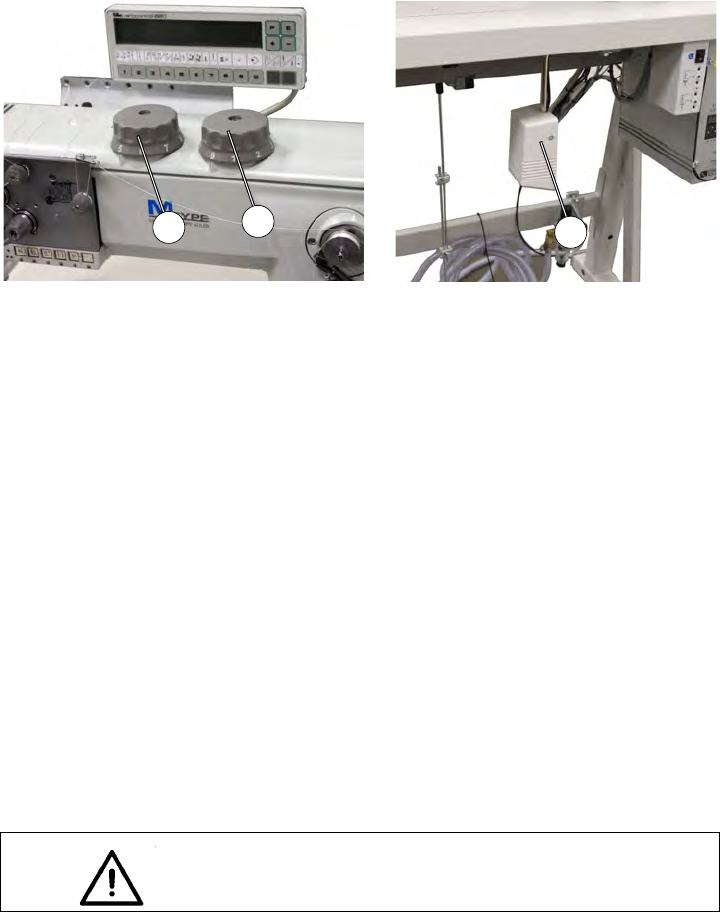

Large horizontal shuttle or oversized shuttle.

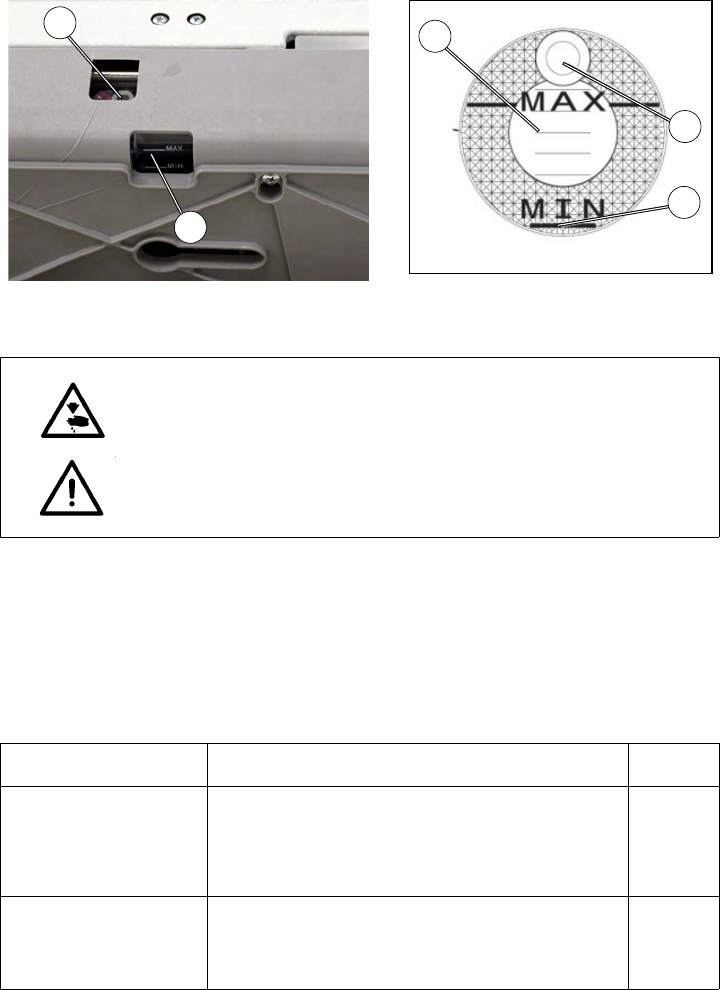

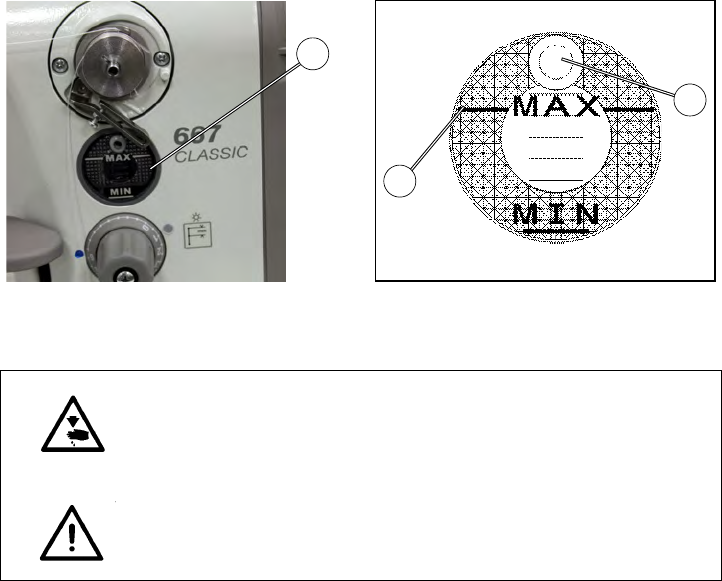

Automatic wick lubrication with viewing windows for the oil level.

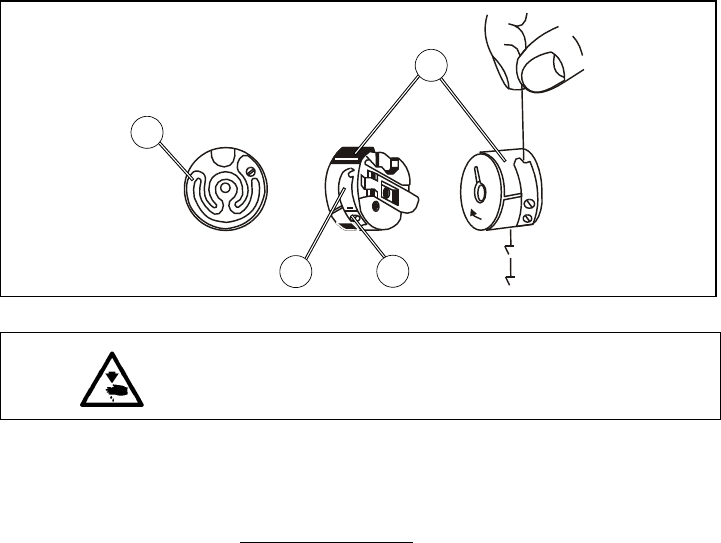

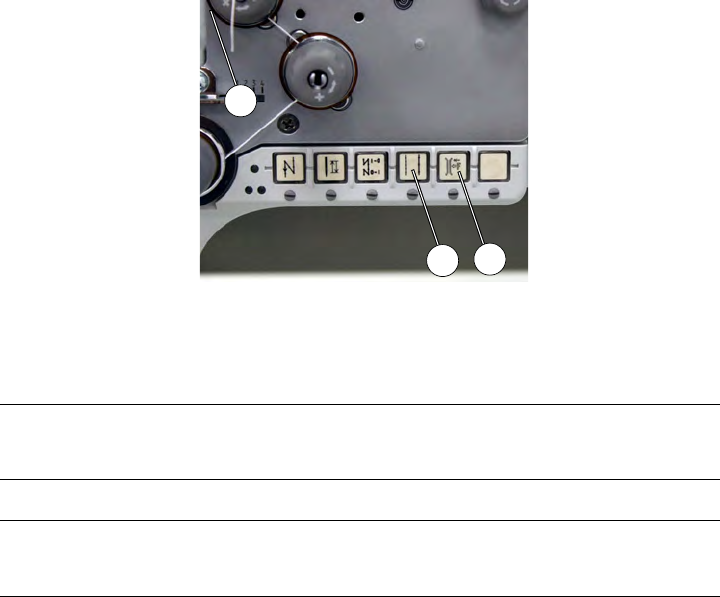

Integrated bobbin winder.

2.2 Proper Use, Designated use

The 667 is a sewing machine designed for sewing light to medium-heavy

material. Such material generally consists of textile fibres, but can also

include leather. It is used in the clothing industry and for domestic and vehicle

upholstery.

This special sewing machine can also be used to produce so-called technical

s

eams. In this case, however, the operator must assess the possible dangers

which may arise (with which DÜRKOPP ADLER AG would be happy to

assist), since such applications are, on the one hand, relatively unusual and,

on the other, so varied that no single set of criteria can cover them all. The

outcome of this assessment may require appropriate safety measures to be

implemented.

Generally-speaking only dry material should be sewn with this machine. The

ma

terial should be no thicker than 10 mm when compressed by the lowered

sewing feet. The material should not contain any hard objects; if it does, the

machine should only be operated with eye protection. No such eye protection

can currently be provided.

The seam is generally produced with textile-fibre sewing thread of gauge up

to

15/3 NeB (cotton), 15/3 Nm (synthetic) or 15/4 Nm (covering yarn). Before

using any other thread the possible dangers arising must be assessed and

appropriate safety measures implemented if necessary.

This special sewing machine should only b

e set up and operated in dry, well-

maintained premises. If the sewing machine is used in premises which are not

dry and well-maintained,

it may be necessary to implement further precautions (which should be

ag

reed in advance - see EN 60204-31:1999).

As manufacturers of industrial sewing machines, we proceed on the

assumption that personnel who

work with our products will have received

training that is at least sufficient to acquaint them with all of the normal

operations and with any hazards that these may involve.

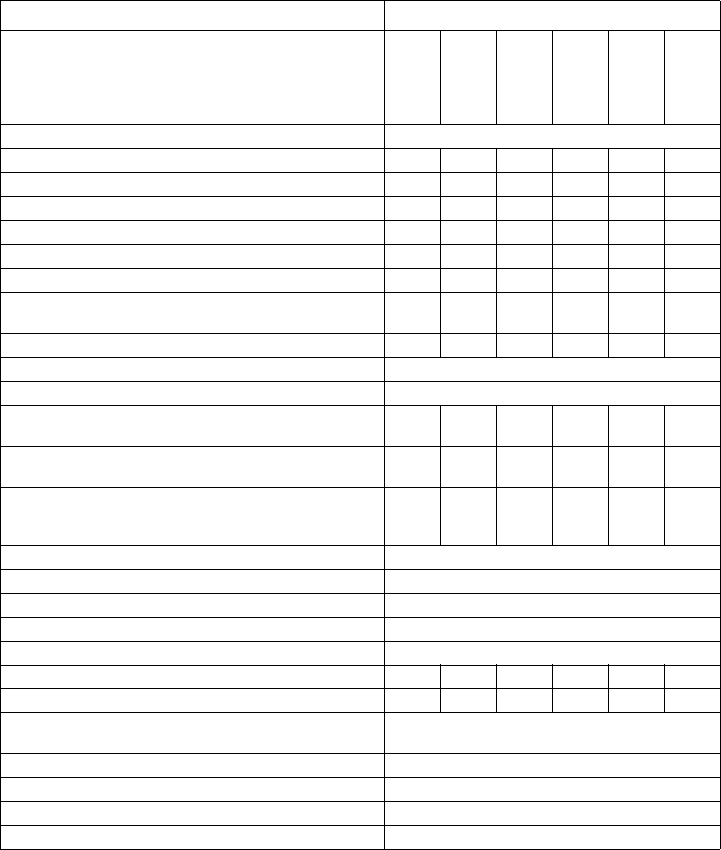

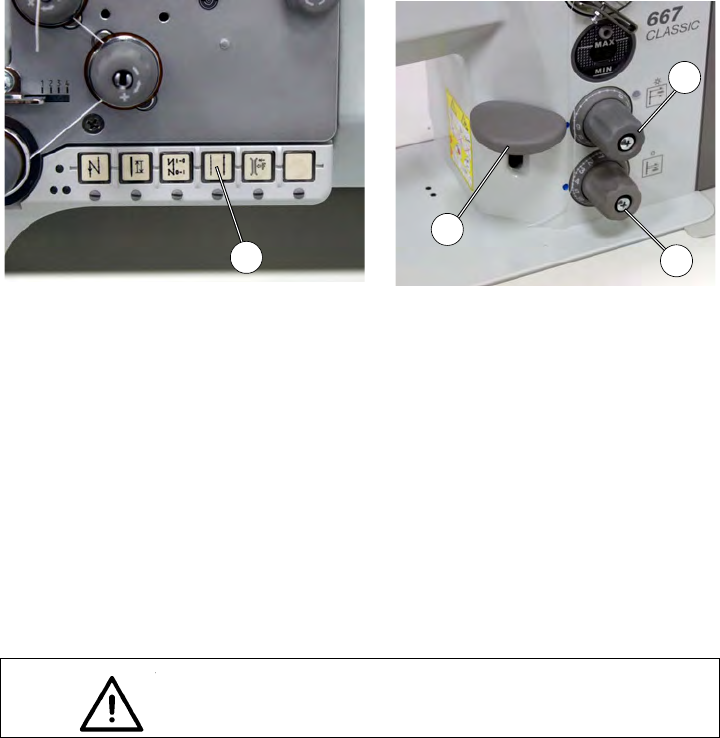

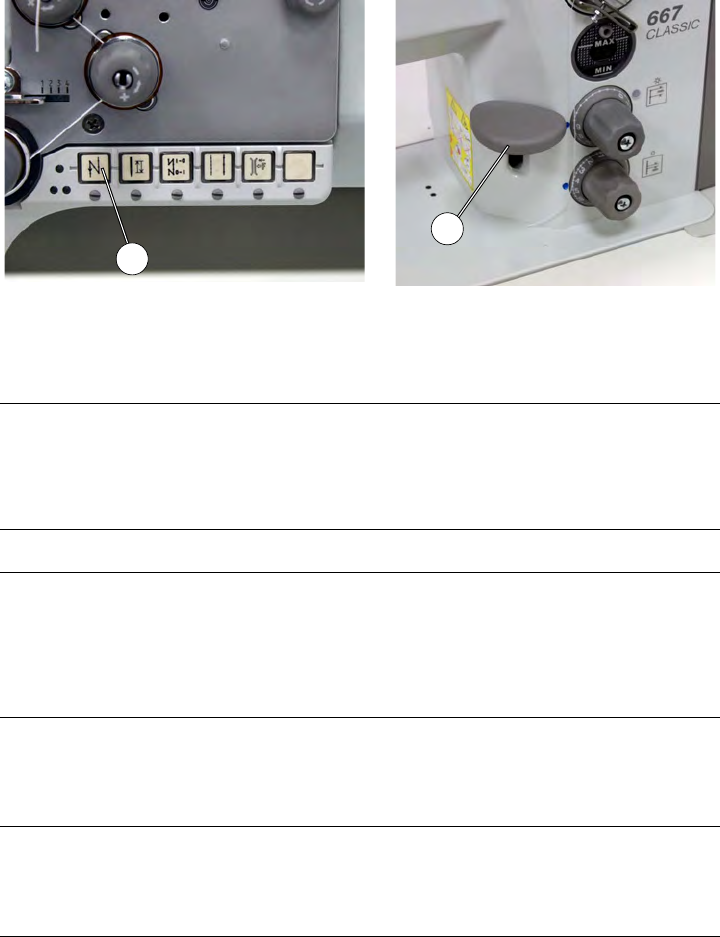

2.3 Specifications

Noise: Workplace-related emission value in accordance with DIN EN ISO 10821

667 LC = _dB (A)

Stitch length: _ mm, Sewing foot strok

e: ___ mm, Stitch rate: ____ rpm