Code Rev. D 20140818 (IEC)

All the wine racks slide out for easy access, except

for the bottom shelf. For easy access to the bottles

stored, pull the rack out gently until it stops. The

shelves are designed with an emergency stop to

prevent them being removed too far when loaded.

Many bottles may differ in size and dimensions. As

such the actual number of bottles you may be able

to store may vary.

Bottle capacities are approximate maximums when

storing traditional Bordeaux 750 ML bottles and

include bulk storage.

You may load your wine bottles in single row or by

stacking while taking note of the following - if you do

not have enough bottles to fill your wine cellar, it is

better to distribute the load throughout the wine

cellar so as to avoid “all on top” or “all below” type

loads.

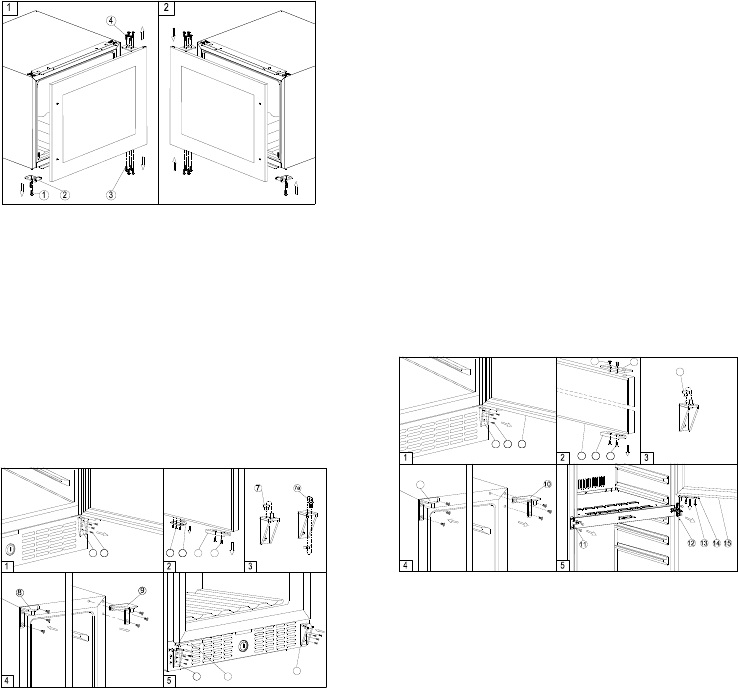

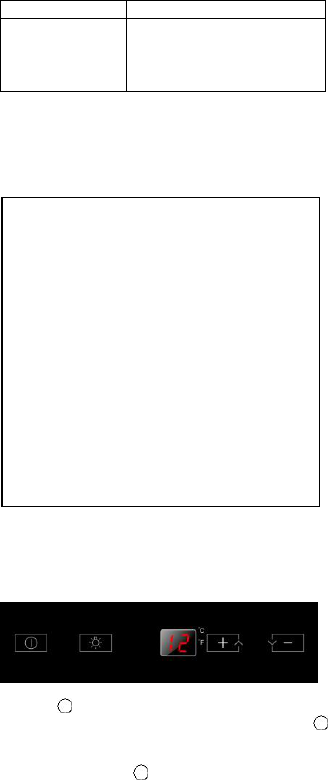

- Do remove or relocate adjustable wooden

racks to accommodate larger type of bottles or

increase the capacity of the cellar by stacking

the bottles up when necessary. (See removing

shelves)

- Keep small gaps between the walls and the

bottles to allow air circulation. Like an

underground cellar air circulation is important

to prevent mould and promote a better

homogeneous temperature.

- Do not over load your wine cellar to facilitate

air circulation.

- Lay the bottles flat.

- Avoid obstructing the internal fans (located

inside on the back panel of the unit).

- Do not cross contaminate. Store only wine in

your unit to ensure that the environment is

odor free.

- Only store wine in unopened bottles. Storing

opened bottles may result in spillage.

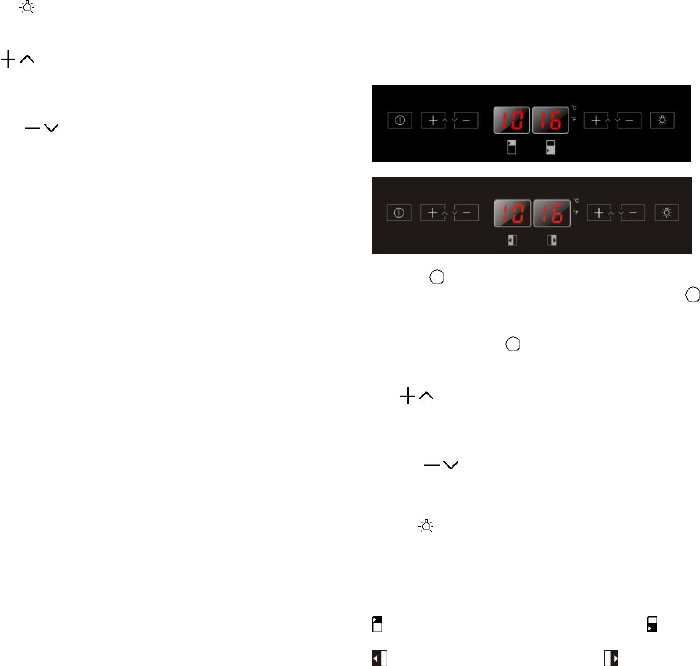

DYNAMIC CLIMATE / SILENT MODE

This Dynamic Climate mode enables the relative

humidity inside the unit and the temperature to be

distributed evenly around the interior so you can

store all your wine under exactly the same excellent

conditions. If you would like to use the unit to store

wine long term, the dynamic climate mode is a must.

This will create a continuous climate in the cabinet

which imitates that of a wine cellar.

In the Dynamic Climate mode, the interior fan

circulates the inside air evenly even the set

temperature is reached. Dynamic Climate mode is

NOT the factory preset mode because of creating

noises and more energy consumption. To change to

Dynamic Climate mode, touch and hold the DOWN

key for approximately five seconds. The wine cellar

will beep five times to confirm Dynamic Climate

mode is on. To change back to default (Silent) mode

(Also named as energy saving mode), touch and

hold the UP key for approximately five seconds.

The wine cellar will beep three times to confirm

default (Silent) mode is on.

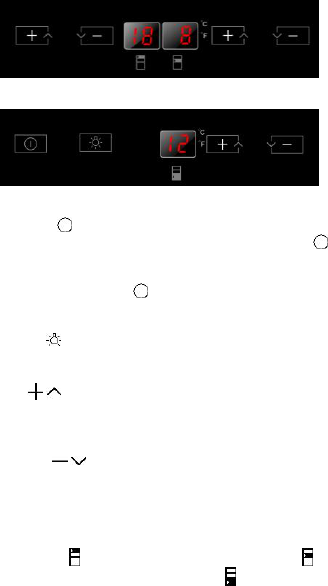

SABBATH MODE

Sabbath mode is available for the observance of

certain religious holidays. This mode turns off the

displays, interior light and audible alarms and

prevents them from turning on again. Normal cooling

operations will still take place.

To initiate Sabbath mode, press the POWER and

LIGHT keys at the same time for at least 5 seconds.

The indicator light will flash four times and confirm

the Sabbath mode is ON.

Sabbath mode can be exited by repeating the above

process. The Sabbath Mode will automatically exit

after 96 hours.

ECO DEMO MODE

Eco Demo mode can be activated by presenting the

appliance at exhibitions or in salesrooms. In Eco

Demo mode, the compressor and all fan motors are

switched OFF.

By pressing and holding the “UP”&“DOWN” (The

controls of lower zone for dual zone & three zone

models) and “LIGHT” keys at the same time for at

least 5 seconds, the indicator light will flash five

times to confirm the input and the unit will operate in

Eco Demo mode. Eco Demo mode can be exited by

repeating the above process.

OPERATING NOISES

The unit is cooled by a compressor (refrigeration

aggregate). The compressor pumps coolant through

the cooling system, producing operating noise. Even

when the compressor cuts out, noises caused by

changes in temperature and pressure are

unavoidable. Operating noise will be most audible

immediately after the compressor cuts in. It

becomes quieter as the operating period continues.

The following noises are normal and occur from time

to time:

- Gurgling sound, caused by the refrigerant flowing

through the appliance’s coils,

- Humming noise made by the motor compressor.

This noise can get louder for brief periods when

the motor is switching on.

- Cracking/popping sounds, resulting from the

materials contraction and expansion due to

temperature variations,

- Fan operating sound, to circulate the air within the

wine cabinet.

Unusual noise is normally the result of improper

installation. Under no circumstances must tubing

come into contact with a wall, other furniture or with

other tubing.

Where the unit is installed in open-plan kitchen or in