63

Prior to installation

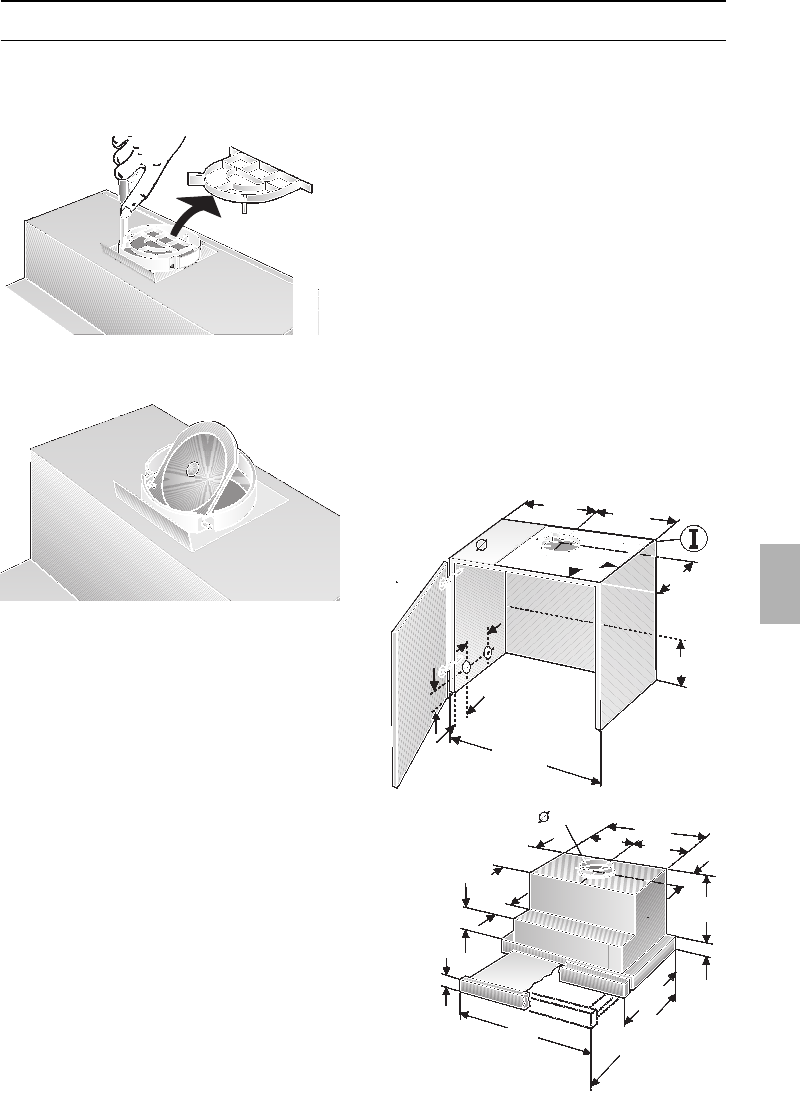

2. Insert the one-way flap into the bearing

apertures on the air-pipe connector.

If the exhaust air is going to be

discharged into the open, a telescopic

wall box should be fitted into the outside

wall.

For optimum extractor hood efficiency:

❑

Short, smooth air exhaust pipe.

❑

As few bends in the pipe as possible.

❑

Diameter of pipe to be as large as

possible (ideal is l 120 mm ) and no

tight bends in pipe.

If long, rough exhaust-air pipes,

many pipe bends or smaller pipe

diameters are used, the air extraction

rate will no longer be at an optimum

level and there will be an increase in

noise.

ṇThe manufacturer of the

extractor hoods accepts no liability

for complaints which can be

attributed to the design and layout of

the pipework.

❑

Round pipes:

We recommend

Internal diameter at least. 120 mm.

❑

Flact ducts must have an internal

cross-section that equates to that of

round pipes with a 100/120 mm internal

diameter

There should be no sharp bends.

l 100 mm approx. 078 cm

2

l 120 mm approx. 113 cm

2

If pipes have different diameters:

❑

Insert sealing strip.

❑

For exhaust-air mode, ensure that

there is an adequate supply of fresh air.

Exhaust air flows upwards:

❑

Cut a hole in the top of the wall cupbo-

ard, including a groove for the mains

cable.

– Template

O

I lis enclosed –.