35

Before installation

Optimum performance of the extractor

hood:

❑ Short, smooth exhaust-air pipe.

❑ Minimum number of pipe bends.

❑ Largest possible pipe diameter

(120 mm dia. recommended) and large

pipe bends.

If long, rough exhaust-air pipes,

many pipe bends or smaller pipe

diameters are used, the air extraction

rate will no longer be at an optimum

level and there will be an increase in

noise.

ṇThe manufacturer of the

extractor hoods accepts no liability

for complaints which can be

attributed to the design and layout of

the pipework.

❑ Round pipes:

Short discharge pipe:

Inner diameter at least 100 mm,

extended discharge pipe:

Inner diameter at least 120 mm.

❑ Flat ducts must have an inner cross-

section equivalent to round pipes with

an inner diameter of 100/120 mm.

There should be no sharp bends.

100 m dia approx. 178 cm

2

125 m dia approx. 113 cm

2

❑ If pipe diameters differ:

Insert sealing strip.

❑ Ensure an adequate air supply for

exhaust-air mode.

If the exhaust air is conveyed through

the exterior wall, a telescopic wall box

should be used.

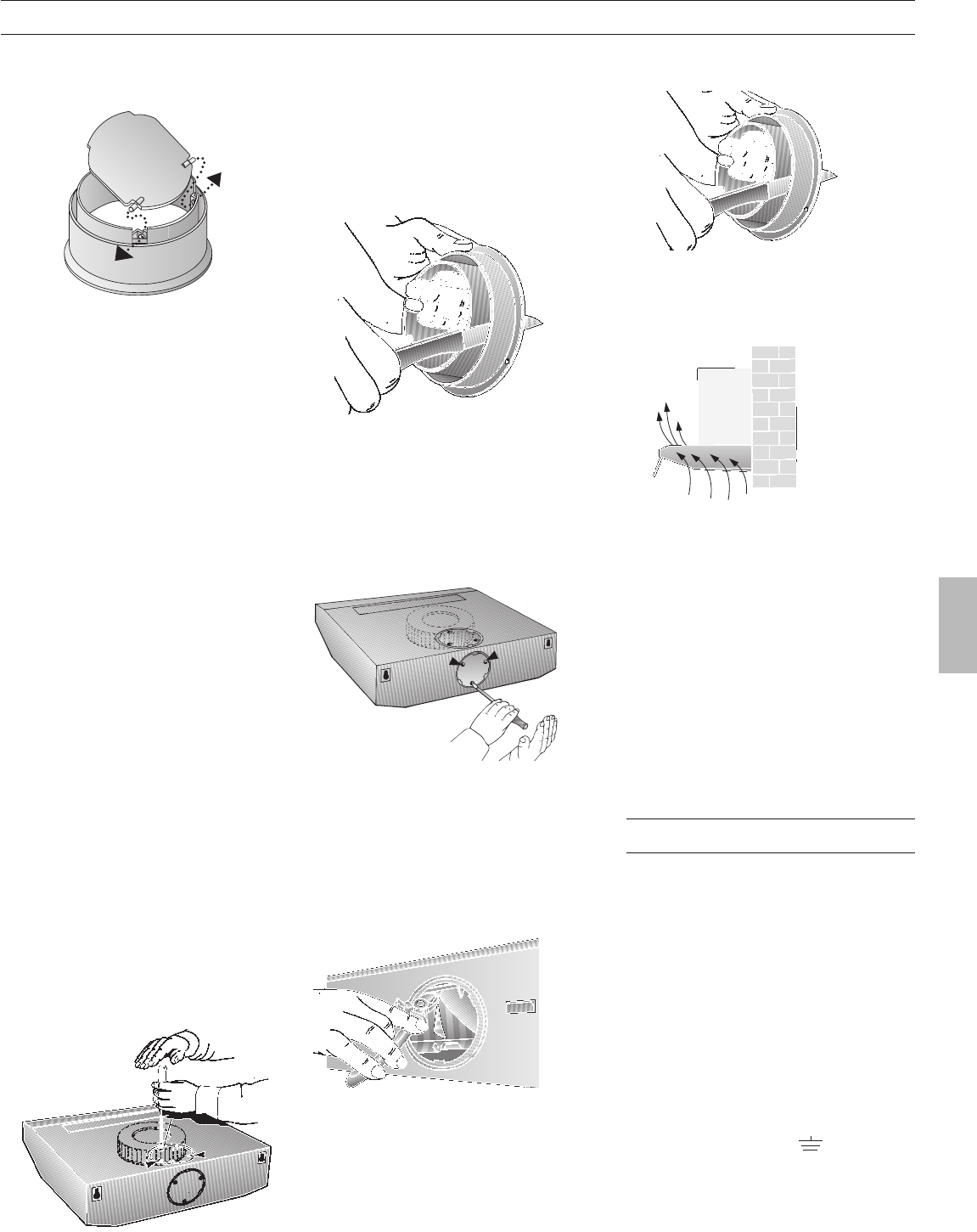

Exhaust air upwards:

Pipe diameter: 100 or 120 mm

❑ Break off cover on the top of the

extractor hood; strike the retaining points

with a tool.

ṇTo prevent damage to the fan, hold the

tool vertically.

❑ Remove the broken off metal part

(possibly a noisy and disruptive

procedure).

❑ If the pipe diameter is 120 mm, cut out

the inner part of the exhaust-air

connection.

❑ Insert the exhaust-air connection and

turn as far as possible.

ṇTo prevent damage to the fan, hold the

tool vertically.

❑ Remove the broken off metal part

(possibly a noisy and disruptive

procedure).

❑ If the extractor hood has 2 motors, the

opening on the plastic part must be

made at the rear; cut through the 3 ribs

and remove the cut-off part.

Exhaust air towards the rear:

Pipe diameter: 100 mm

❑ Break off cover on the rear panel of the

extractor hood; strike the retaining

points with a tool.

❑ Cut off the outer part of the exhaust-air

connection.

❑ Insert the inner part and turn as far as

possible.

Circulating-air mode

❑ With activated carbon filter if exhaust-air

mode is not possible.

❑ The air purified by an additional

activated carbon filter is conveyed back

into the room.

❑ For insertion of the activated carbon

filter see Instructions for use.

❑ If the extractor hood is switched from

exhaust-air mode to circulating-air

mode, the exhaust-air opening must be

sealed to prevent a hazardous situation

(see optional accessories in the

Instructions for use).

Electrical connection

WARNING: THIS APPLIANCE MUST BE

EARTHED

IMPORTANT: Fitting a Different Plug:

The wires in the power cord are colour-

coded as follows:

Green and Yellow – Earth

Blue – Neutral

Brown – Live

If you fit your own plug, the colours of these

wires may not correspond with the identify-

ing marks on the plug terminals.

Proceed as follows:

1. Connect the green and yellow (Earth)

wire to the terminal in the plug marked

‘E’ or with the symbol ( ), or

coloured green or green and yellow.

2. Connect the blue (Neutral) wire to the

terminal in the plug marked ‘N’ or

coloured black.

3. Connect the brown (Live) wire to the

terminal marked ‘L’, or coloured red.