Installation Step 7

Connect Electric Power

TO AVOID SERIOUS PERSONAL INJURY

FROM ENTANGLEMENT, REMOVE ALL

ROPES CONNECTED TO THE GARAGE

DOOR BEFORE OPERATING OPENER.

TO AVOID DAMAGE TO GARAGE DOOR

AND OPENER, MAKE DOOR LOCKS

INOPERATIVE BEFORE CONNECTING

ELECTRIC POWER. USE A WOOD

SCREW OR NAIL TO HOLD THE LOCKS IN “OPEN”

(UNLOCKED) POSITION.

INSTALLATION AND WIRING MUST BE IN

COMPLIANCE WITH LOCAL ELECTRICAL AND

BUILDING CODES.

OPERATING AT OTHER THAN 120V 60Hz WILL

CAUSE OPENER MALFUNCTION AND DAMAGE.

USE MANUAL RELEASE ROPE ONLY TO

DISENGAGE TROLLEY. DO NOT USE

ROPE AND HANDLE TO PULL DOOR

OPEN OR CLOSED.

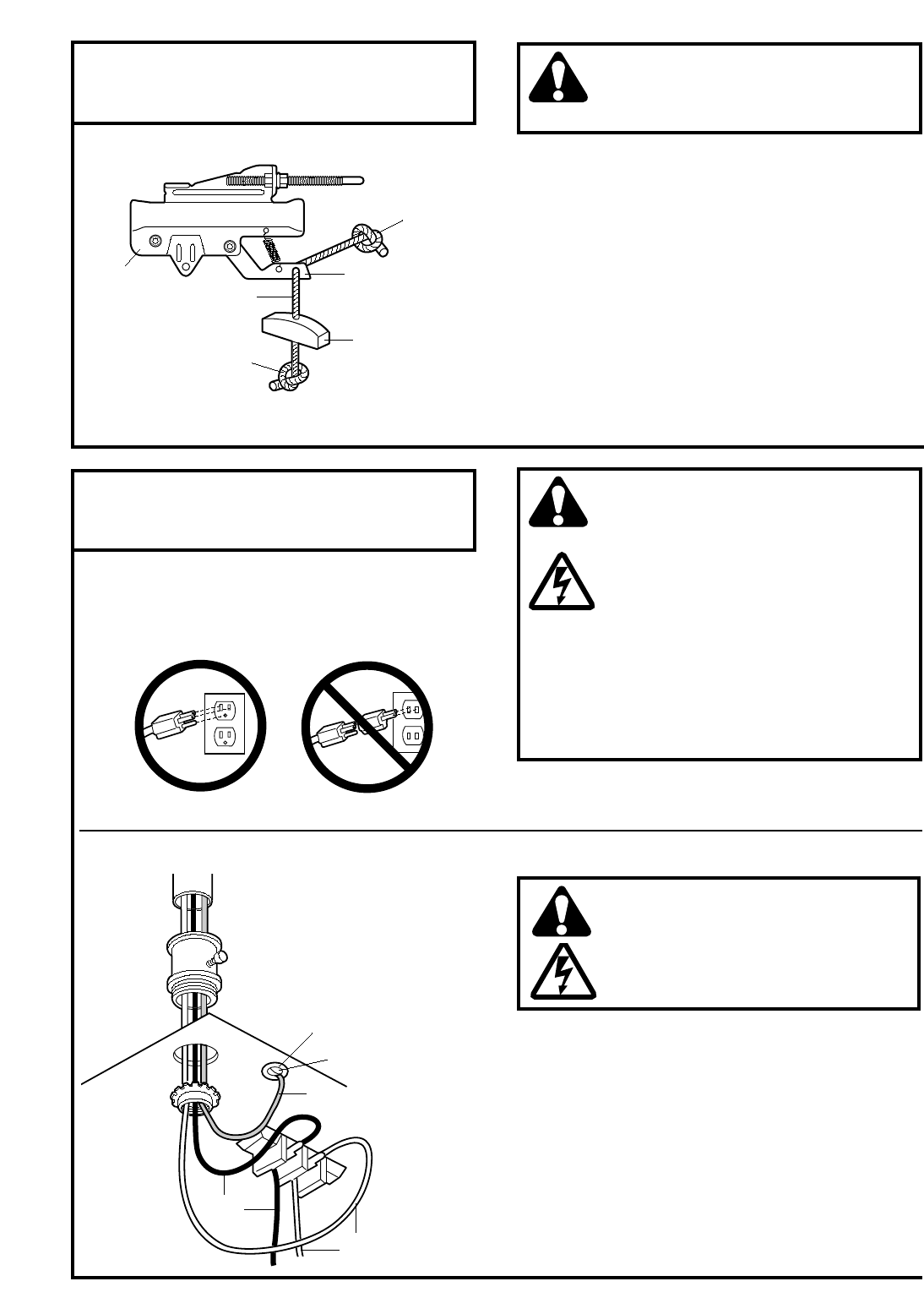

PROCEDURE FOR PERMANENT WIRING

16

DISCONNECT THE POWER AT THE FUSE

BOX BEFORE PROCEEDING.

Refer to illustration. Make connection through the

22mm diameter hole in top of opener.

1. Remove opener cover screws and set cover aside.

2. Remove attached 3-prong cord.

3. Connect black (line) wire to black wire on terminal

block; white (neutral) wire to white terminal wire;

ground wire to green ground screw.

CAUTION: BE SURE THAT THE UNIT IS

GROUNDED ACCORDING TO LOCAL CODE.

IMPORTANT NOTE: TO AVOID INSTALLATION

DIFFICULTIES, DO NOT RUN OPENER NOW.

Installation Step 6

Attach Manual Release Rope & Handle

PROCEDURE: Thread one end of rope through hole

in top of red handle so "NOTICE" reads right side up

as shown. Secure with an overhand knot.

NOTE: Knot should be at least 25mm from the

end of the rope to prevent slipping.

Thread other end of rope through hole in release arm

of outer trolley. Adjust rope length so that handle is

1.8m above the floor. Secure with an overhand knot

as above.

NOTE: If it is necessary to cut rope, heat seal cut

end with a match or lighter to prevent fraying

and/or raveling.

Opener MUST be permanently wired or plugged into

a grounded 3-prong receptacle wired according to

local electrical codes. DO NOT use a 2-wire adapter.

DO NOT USE an extension cord.