KGI

>"!""

"$ ."""$

%',D)E'&

""$

%',DE('&

B""$

%',D,E'&

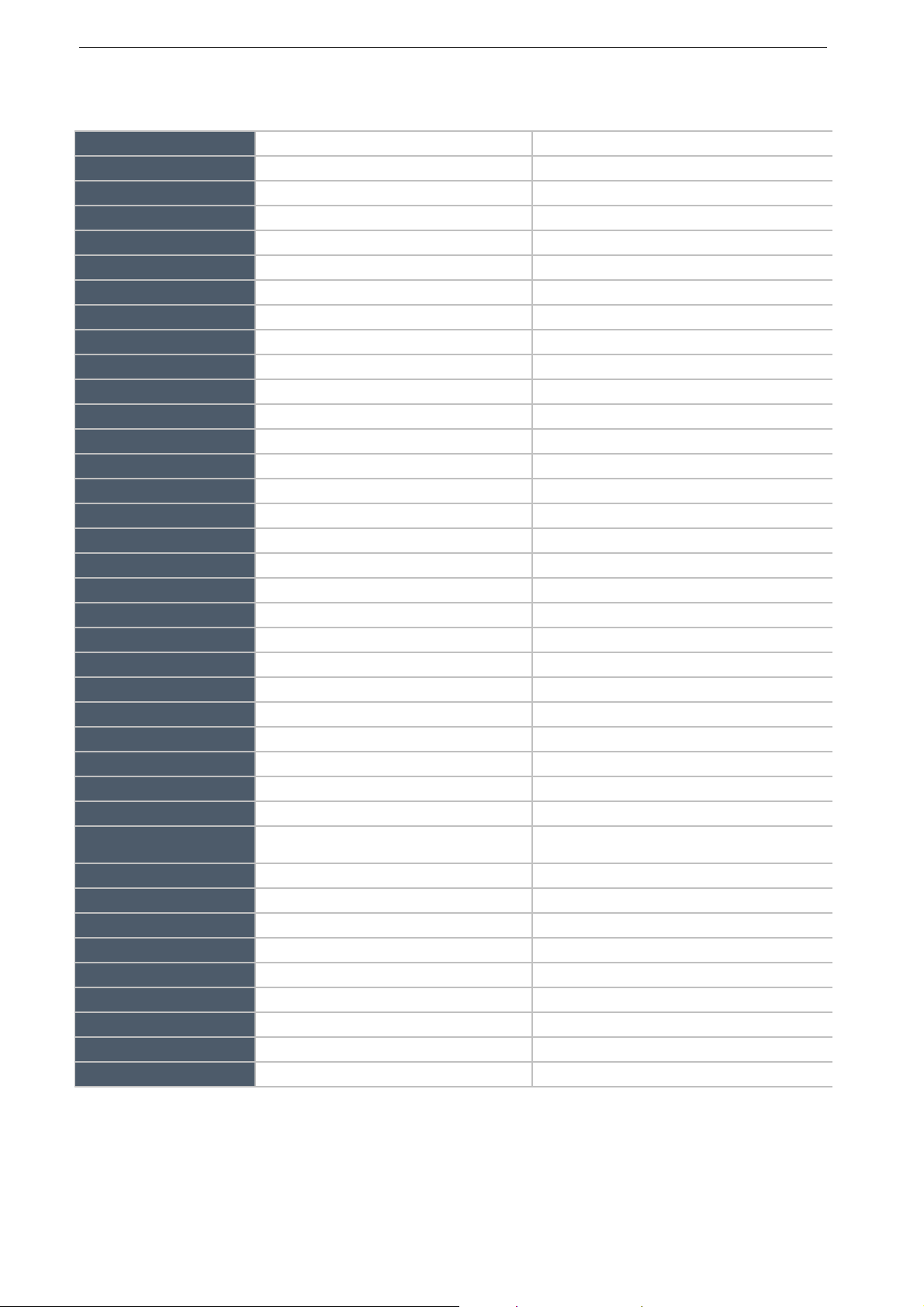

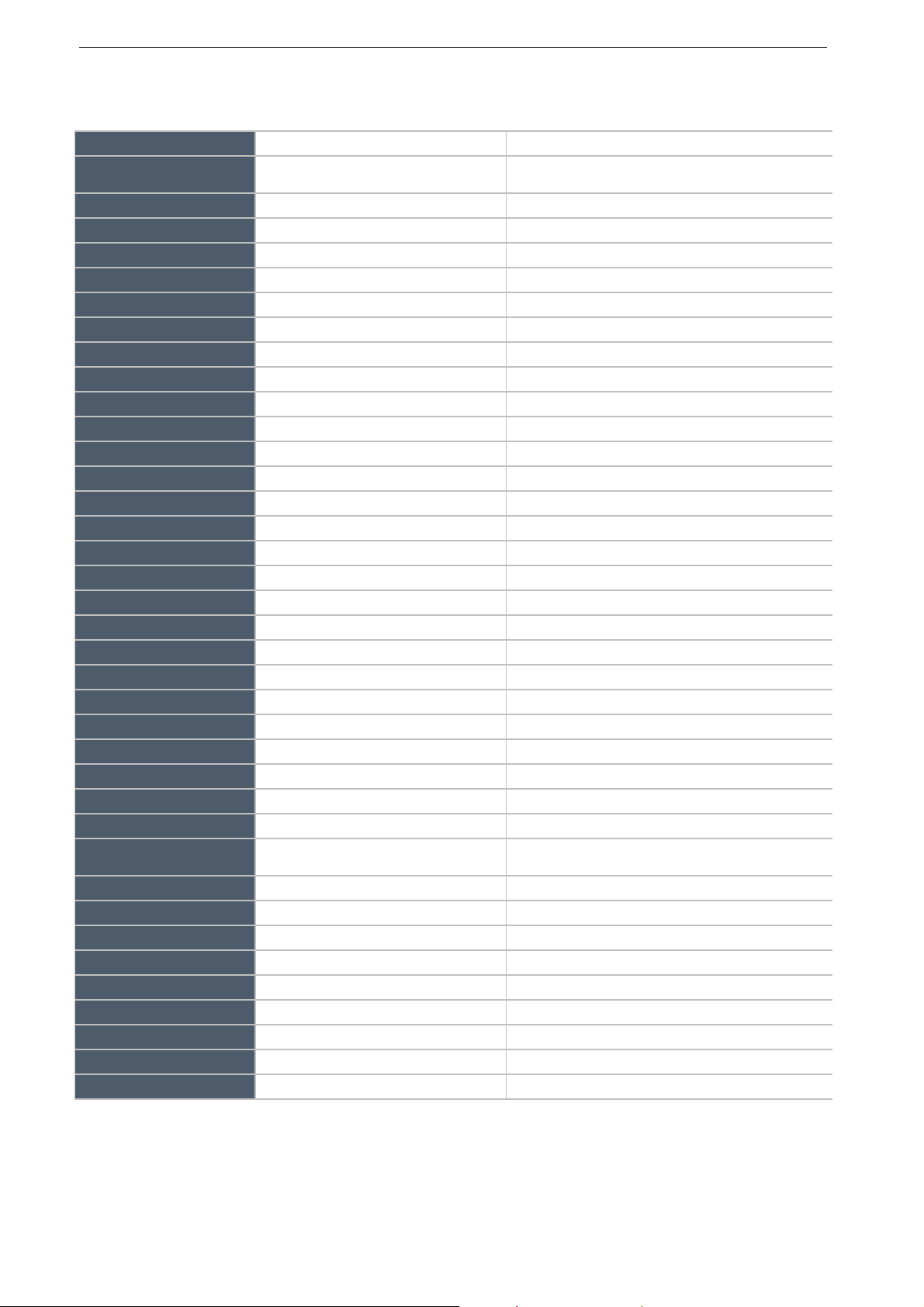

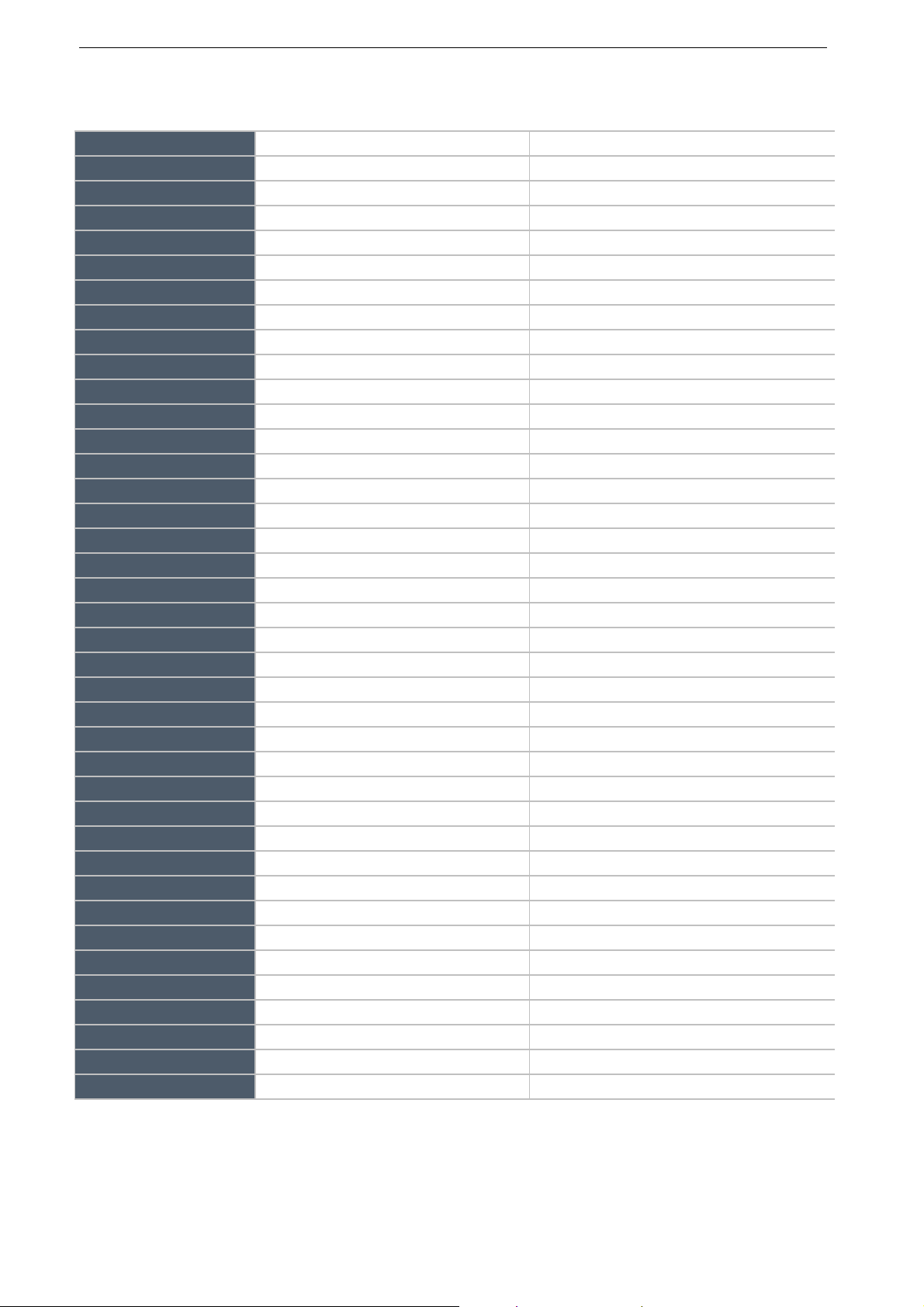

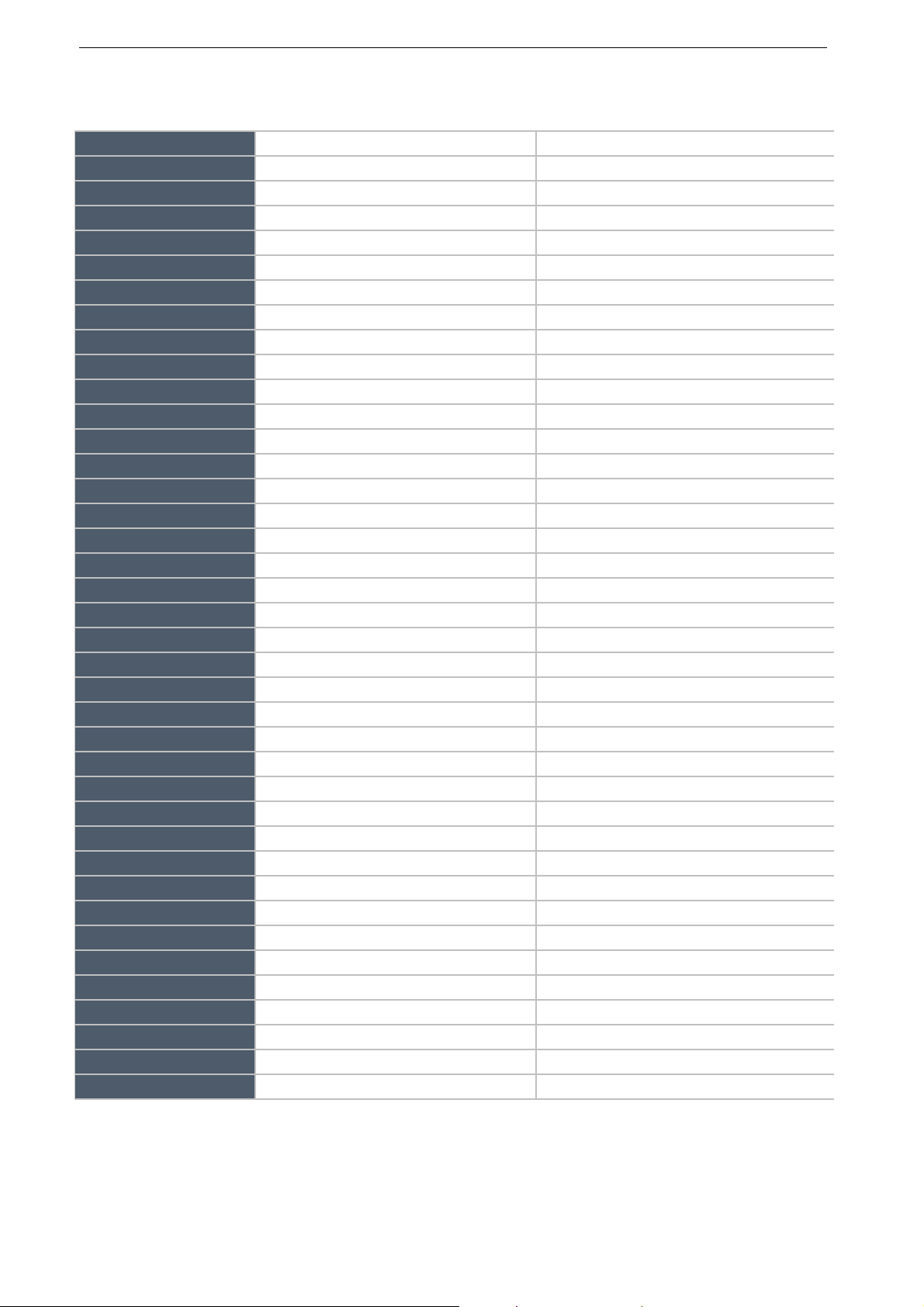

[!! ABC ABC ABC

!$ J\ ]]_ `]]_ ]]_

Ta U( ]]_ ]]_ ]]_

AG$ Jb _ _ _

BGQ - _-

BG

I[,[*MQ G

I[,[*MQ G _

I[,[*MQ G

dB ]]e ]]e ]]e

C dB eF]]e eF]]e eF]]e

OGMQ * f _ F

[ #[] #[] #[]

- GG!]-NG[,[*!NBeP

GN!$gShNJGN$!NN$!LN!

J "

."0

$"$"%$01&

="C""#!"$G$NG

,GG$N!G

NGGBG*!J

!J

[G!$%'&NG,G

!$*%&GG

BG,LNG

"$$#"C%$0&

C,GGNN!$NG!G

A*OG!M!!$GL

NG

0"C !"!"0"!C

-$!!M!MGG*

!

[GG%&NGGG

*%,&G

"$$"C%$0"G-&

C,GGNNBG$NGG

*%&-$!!M!MGGL

*!PNG$NG

G*%&!GG%&

GG*%,&

>"0"$"$0

0$"$$0"C

!!CC" !"" 0"

"$$#NGM$G

NGG!!G

OG!M!!$GL

NG

"$$ "

#N,N!A*MG

G!G$!,GM

GG!NGGG

GQ]fI`]iMGGGN

G!GGPKHNGG

OGG*M,!,NGL

#N*GNGG!MG

G!$!

"$$

GGGGL

!GG*G*!

G

5HGG,GGL

NGA*,GG!GL

5HG!$!$!!GGL

GG!,G!,GGL!

OGG,GGL!M

GG!$!G

G!

OGGL!!MGL

NG!

GNG!!GG!L

%*&G!GGL!L

GPKHGG!%*&NG!G

GKG!!PKHL

EBEDF AGA*C