English - 4

Retainer flange for

grinding spindle

M 14

An O-ring (plastic

part) is inserted in

the retainer flange 7

around the spigot.

If the O-ring is missing or is damaged, it must

in all cases be replaced (Order No.

1 600 210 039) before the retainer flange 7 is

mounted.

Retainer flange for

grinding spindle

M 10

The retainer

flange 20 can be

used on both sides.

For diamond cutting

discs it must be posi-

tioned on the grind-

ing spindle 4 and

turned through 180°.

The bore of the diamond cutting disc (Ø 20 mm)

must fit the spigot of the retainer flange 20 with-

out any play.

Do not use any reducers or adapters.

☞

After mounting the grinding tool and be-

fore switching on, check that the grind-

ing tool is correctly mounted and that it

can turn freely.

Flap disc

(for M 14 grinder spindle)

Remove the protective guard 5 and mount the

hand protector 11. Place the special retainer

flange 7 (optional extra, Order No.

2 605 703 028) and the flap disc on the grinder

spindle 4. Screw on the clamping nut 9 and

tighten with the two-pin spanner.

Rubber Sanding Plate 12

Remove the protective guard 5 and mount the

hand protector 11.

For mounting, see the illustration page.

Screw on the round nut 14 and tighten with the

two-pin spanner.

Cup Brush 15/Disc brush

(for M 14 grinder spindle)

Remove the protective guard 5 and mount the

hand protector 11.

The grinding tool must be able to be screwed

onto the grinding spindle 4 until it rests firmly

against the grinder spindle flange at the end of

the grinder spindle threads. Tighten with an

open-ended spanner.

(for M 14 grinder

spindle)

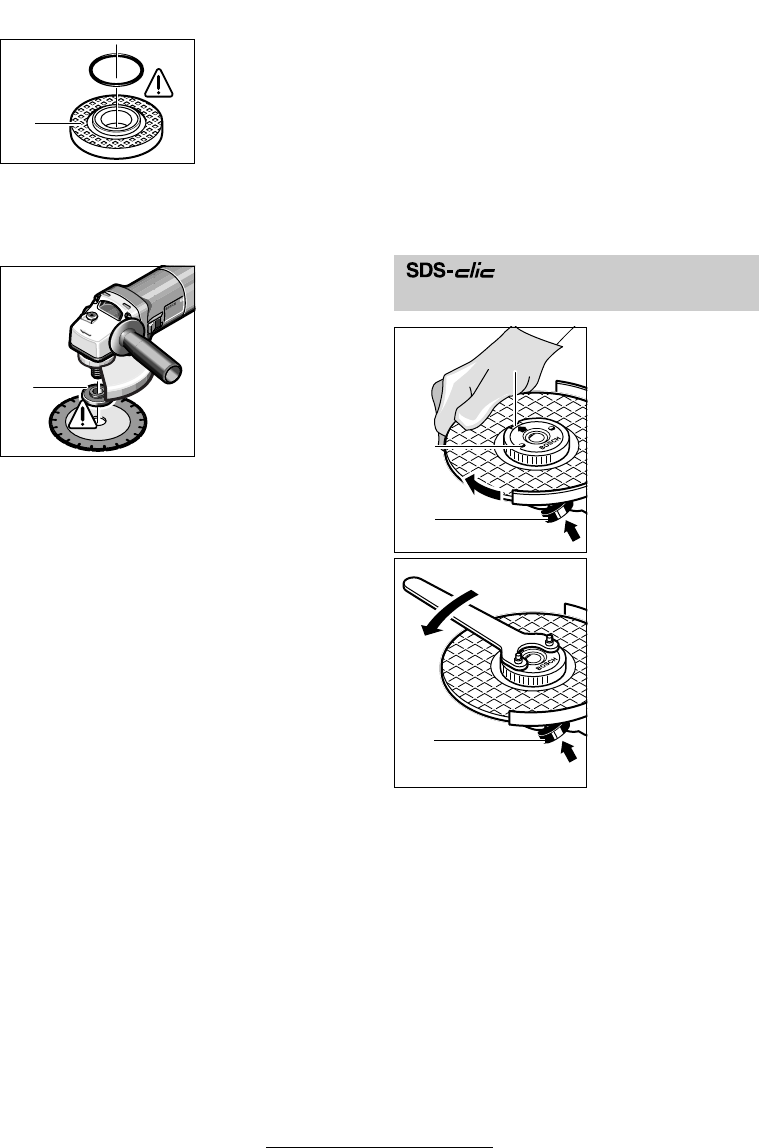

Instead of the clamp-

ing nut 9, the quick

clamping nut 10 (op-

tional extra) can be

used. Grinding tools

can be mounted with-

out using tools.

The quick clamping

nut 10 may be used

only for roughing

and cutting discs.

Use only a flawless,

undamaged quick

clamping nut 10.

When screwing on,

take care that the

side with printing

does not point to the

grinding disc. The ar-

row must point to the

index mark 21.

Lock the grinder spindle with the spindle locking

button 3. Tighten the quick clamping nut by force-

fully turning the grinding disc in the clockwise di-

rection.

A properly tightened undamaged, quick clamping

nut can be loosened by hand turning the knurled

ring in the counter-clockwise direction.

Never loosen a tight quick clamping nut with

pliers but use a two-pin spanner. Insert the

two-hole spanner as shown in the illustration.

7

20

Quick Clamping Nut

(Optional Extra)

3

21

10

3

16 • 1 609 929 807 • TMS • 02.05.01