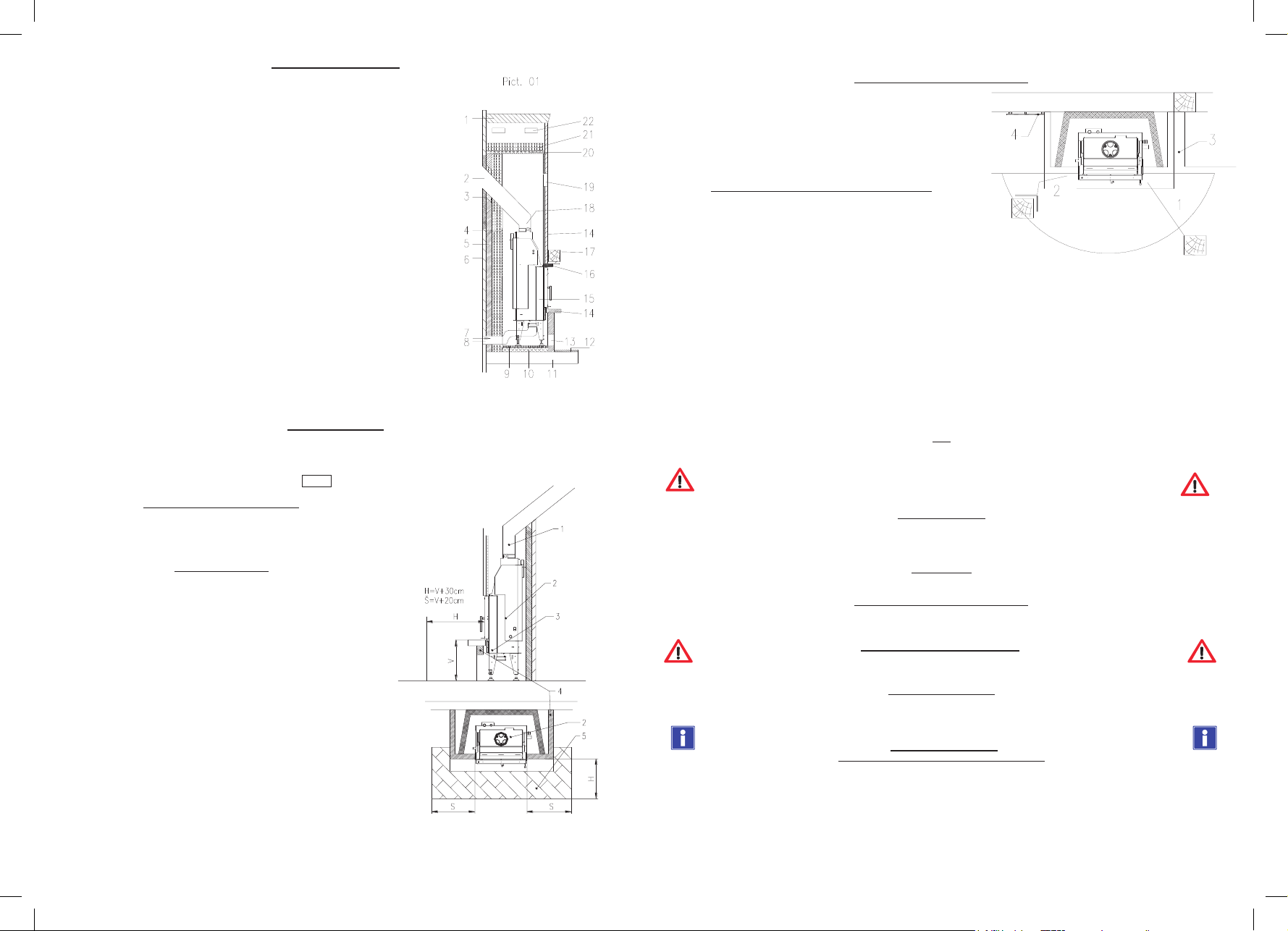

Fireplace insert location diagram

The hot water fireplace inserts in accordance with EN 13229

1.

Protected ceiling made of combustible materials or as a conductive element

2. Artificial construction material: heating protective measure in accordance with national technical

standards and regulations

3. Connecting pieces made of steel sheets

4. Thermal insulation layer: back wall, side wall, ceiling, convectional air chamber

5. Brick veneer

6. Protected wall made of combustible material or a conductive element made of concrete or iron

concrete

7. External combustion air input

8. Protecting grille

9. Thermal insulation layer

10. Conductive plate

11. Protected base plate made of non combustible material

12. Screening protection of the floor of non combustible material

13. Convection air input

14. Coating

15. Fireplace insert

16. Conductive frame

17. Ornamental beam

18. Butterfly valve d=200mm

19. Grill of air output

20. Conductive element (non combustible material)

21. Thermal insulation layer of 6 cm thickness

22. Interspaces’ ventilation

Ceiling (floor) protection

Ceilings without a sufficient lateral distribution (e.g. wooden ceilings) must be protected by a 6 cm thick concrete layer and 6 cm thick thermal

insulation layer where the fireplace insert is situated. Consulting a structural engineer is recommended. If the floor, where the fireplace insert will be

situated, has an adequate lateral distribution a 6 cm thick thermal insulation layer is enough.

pict. 02

The floors in front of the fireplace insert

A floor made of combustible material in front of the fireplace insert must be protected

by an adequate incombustible material layer. Dimensions of this incombustible area are

at least: 800mm in the sideways direction of the opening side and 400mm to the front in

the direction of the opening side.

The chimney connection

If the existing chimney is not provided with a suitable connecting fitting for the

fireplace insert it is necessary to make an additional connection. The chimney

connection height is arrived at the properly situated fireplace insert and an attached

smoke flue elbow and a connecting fitting – measured from the top edge of the support

plate to the centre of the connecting fitting in the entrance of the connecting area. Gaps

for the surround, insulation, expansion joint, etc. must be taken into account. pict. 02

1 – smoke flue

2 – fireplace insert

3 – bottom of the hearth

4 – surround

5 – floor

Before starting the unit for the first time it is necessary to let authorized

person do the inspection in accordance with national standards.

Fire protection above a heat radiation area

A minimum distance of 5 cm from the outer space of the insert coating to non-

combustible building panels must be retained. Air space must be clear so as not

to accumulate heat (pict. 6, position 3). Building panels covering only small

coated areas of the fireplace insert, e.g. floors, wall coating and thermal

insulation layers may abut onto the coating (pict. 6, position 4). Wider

combustible building panels, e.g. ornamental beams, may be at a distance of 1 cm

from the insert coating.

External air input for combustion into the fireplace insert

Hot water fireplace inserts are adjusted for direct connection for external

combustion air inflow. Bellmouth of diameter of 120 – 150 mm for external

combustion air connection is ending on the back side (or bottom side) of the

fireplace insert. Inflow for outdoor air connection for combustion in a fireplace

insert must have as few bends as possible. For air inflow within the distance of

1.5 m with one bend (max. 90°) it is possible to use a pipe of diameter 100 mm.

For air inflow within the distance of 3 m with one or two bends (total disjunction of angles 135°) it is possible to use a pipe of diameter 125 mm.

When there is longer distance and more bends, it is necessary to take into account air resistance caused by friction of tube walls.

It is possible to supply hot water fireplace inserts with automatic electronic regulation of the combustion process. Automatic regulation consists

of control unit, control damper and temperature sensor. Control dumper must be situated in supply pipes, as close as possible to fireplace insert

and connect hermetically onto bellmouth of the air inflow. After building of the fireplace, the dumper must be accessible for service. When

automatic regulation is in use, it is convenient to set up the hand-operated element in the 2/3 open position (providing right proportion of the air

for nominal output of the insert). Also, fireplace insert can be fitted with door contact for easy service (position of the door contact is described

below in paragraph “door adjusting and unhanging). More detailed description of connection and installing you will find in installing document

of Automatic regulation.

When automatic regulation is in use, manually operated element must not be closed!

Fireplaces with open hearth must be supervised all the time to prevent dangerous sparks and falling out wood pieces burning.

Fuel

Fireplace inserts can be operated only with the following fuel:

dry wooden logs

ONLY DRY WOOD LIBERATES LITTLE HARMFUL POLLUTANTS DURING BURNING!!!

A fireplace insert is not suitable for waste burning!!!

Combustion air input

It is necessary to supply a sufficient amount of external air into the room when using the fire. Both open and closed fireplaces require an

adequate amount of fresh air. The steps for combustion air input cannot be changed and combustion air inputs must be open during the working

operation of the firebox.

Convection air

To prevent heat accumulation, the incoming and outgoing grates of convection air must be open when using the fire.

Fire protection above a heat radiation area

A minimum distance of 5 cm from the outer space of the insert coating to non-combustible building panels must be retained

Fire protection in a heat radiation area

A minimum distance of 80 cm forwards and sideways must be retained in front of the firebox hole - (furniture, carpets,

plants etc.)

Protection against injuries

Do not forget that heaters have hot surfaces. Use the enclosed protective glove when working with the fire. You could be in a heat radiation area

(80 cm) only during mending, and if there is further contact, the skin can be burnt. Keep the fireplace out of the reach of children.

Application and activation

Acceptable fuel, economical and ecological operation:

The fireplace insert is designed to use wood as fuel. The water content is max. 20% of dry weight. Logs should be stored in a dry and well

ventilated place for two years. Using wet logs leads to smoke with a tar condensation which could damage the chimney. In any case there is

excessive environmental pollution. Logs should be 30 cm.

Wood is a very gaseous fuel and needs a lot of secondary air. Regulation with the help of slow or permanent burning is not possible with this

kind of fuel. Heating output during wood burning is determined by the amount of the fuel used.

The most ecological and economical is dry wood burning, because the heating quality of fresh wood is lower than that of dry wood.

As for burning waste, it must be stressed, that burning material such as plastic material, cardboard, painted wood, etc. are harmful for your

fireplace insert and furthermore is prohibited by the Emission Act. It is allowed to use firelighters, paper and small wood for lighting a fire only.