h. Handling a ground-out filament

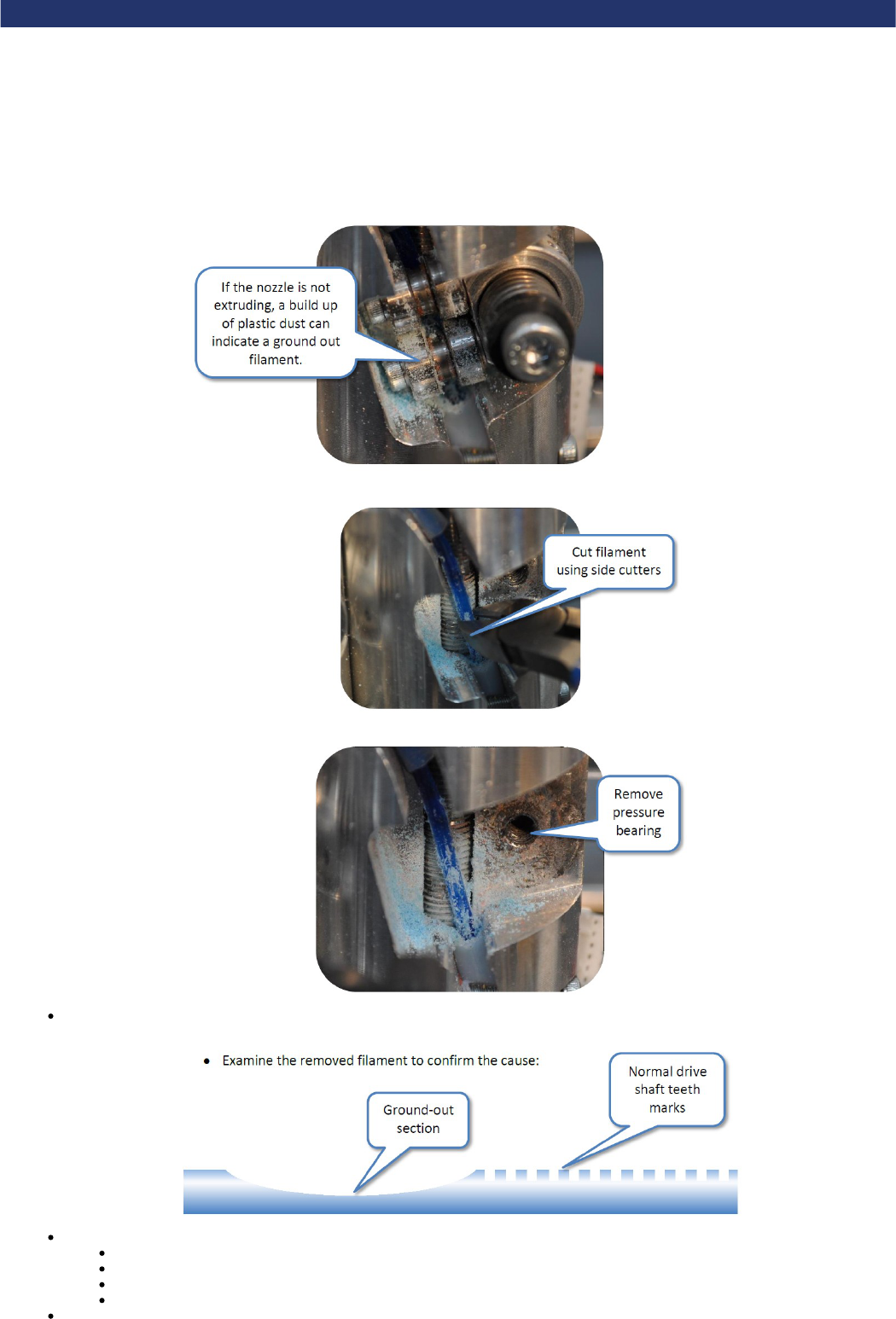

If a pressure bearing is poorly assembled, or the nozzle suffers from a blockage (e.g. printing too close to the bed), the back of the filament may be

ground out by the extruder drive shaft. The drive shaft will then be unable to push the filament down into the nozzle, preventing the extruder from

extruding. This is normally indicated by a fast build-up of plastic dust around the pressure bearing.

Heat extruder to melt plastic using "Extruder control".

Examine the removed filament to confirm the possible cause. Here are some suggestions:

Snagged filament reel preventing filament form entering the extruder

Under tightened pressure bearing

Blocked nozzle from poor filament tip preparation

Nozzle too close to bed during print

Reload the filament, as per "Load the extruders" taking care to prepare the tip of the filament as specified.