37

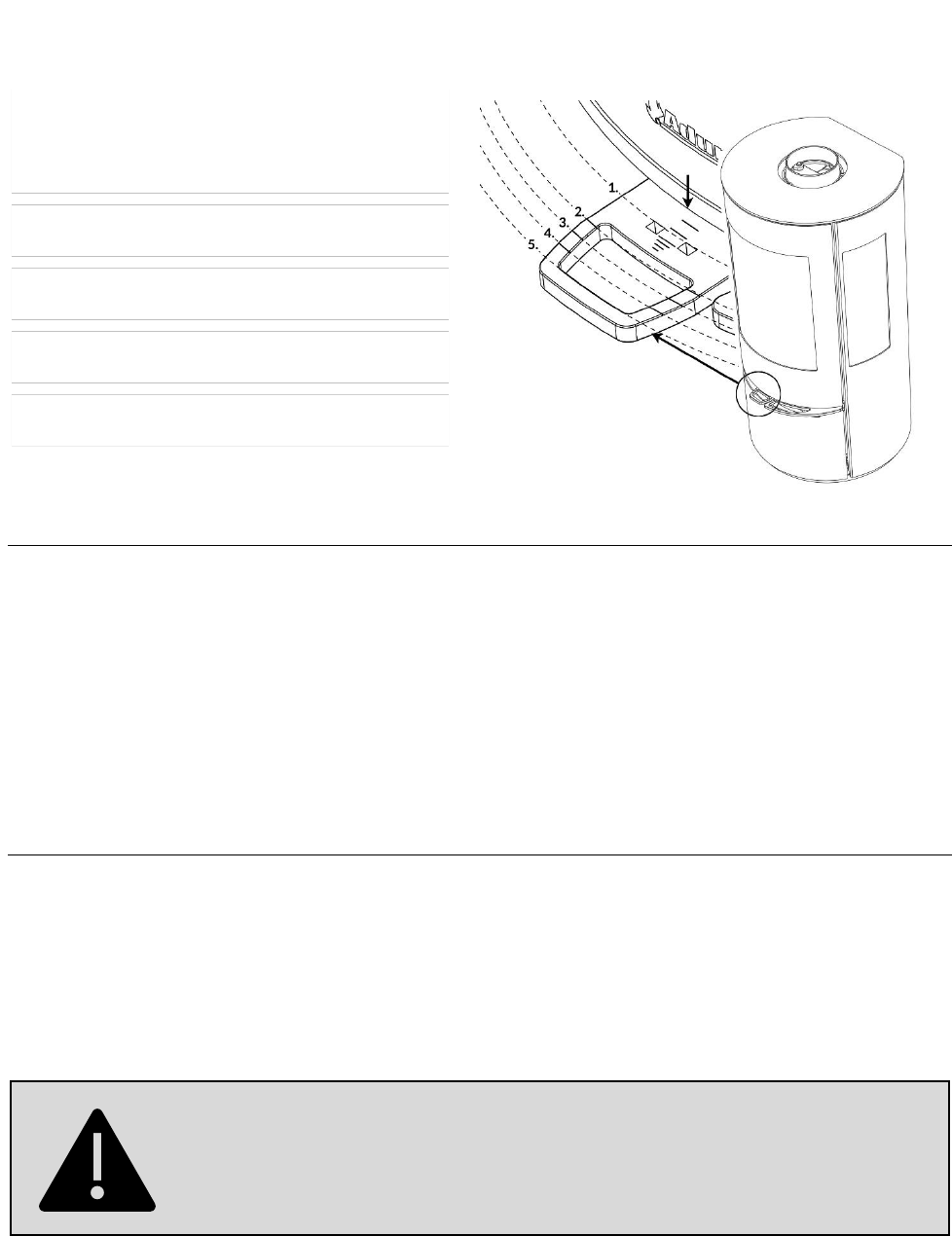

illustration below shows the stove seen from the front with the dampers indicated. Use edge of door to read

position of inlet air:

3.1.1 Secondary air supply

In normal circumstances, the wood burning stove should be working with this damper open between 60 %

and 100 %. You should never close the air intake so far that the flames are extinguished. There should

always be visible flames in order to achieve clean and efficient combustion. A too low supply of air can lead

to bad combustion, high emissions and a bad efficiency. The air-wash system that minimizes soot collecting

on the glass panes is also adjusted by this damper.

If you want to fire the stove with the lowest effect possible – around 3 kW – you must close the secondary

damper almost completely 45 minutes after the wood has been put in. At this point there are only few flames

and the stove can burn clean by using the tertiary air from behind in the stove.

3.1.2 Primary damper

When you add a new log, the primary damper should be opened until the fire is burning properly. In order to

utilize the fuel to the fullest extent, the embers should have burnt for so long that it is necessary to open the

primary damper for approx. 2 minutes to get the new log to burn.

In order to reduce the risk of ash falling from the stove when the door is opened to add more fuel, it is a good

idea to open the primary damper for approx. 1 minute before the door is opened. This increases the draft

through the stove and reduces the risk that ash will drop on the floor.

wood/hour, there is a risk that the lacquered surface of the stove will become

discoloured and eventually fall off. The stove can be resurfaced, but this is not

covered by the manufacturer’s guarantee. In the same way, any other damage to

inlet. This position can be maintained with the

Aduro key, which must be placed in the two

holes.

2: Closed primary air inlet, fully open secondary

and tertiary air inlet.

3: Closed primary air inlet, half way closed