STANDARD PIPELINES CONNECTION & AIR PURGING

No dust or any other particles, air or moisture should be allowed to

enter the air conditioning system. Careful attention should be paid

when pipeline connection for outdoor unit is made. Try to avoid

repeated curves as much as possible; otherwise damage to the

copper pipes may occur. Suitable wrenches should be used when

the pipeline connection is done so as to ensure appropriate torque

(refer to following torque table).

Excessive torque action might damage the joints while too little

torque might lead to leakage.

Torque based upon the wrench to be used

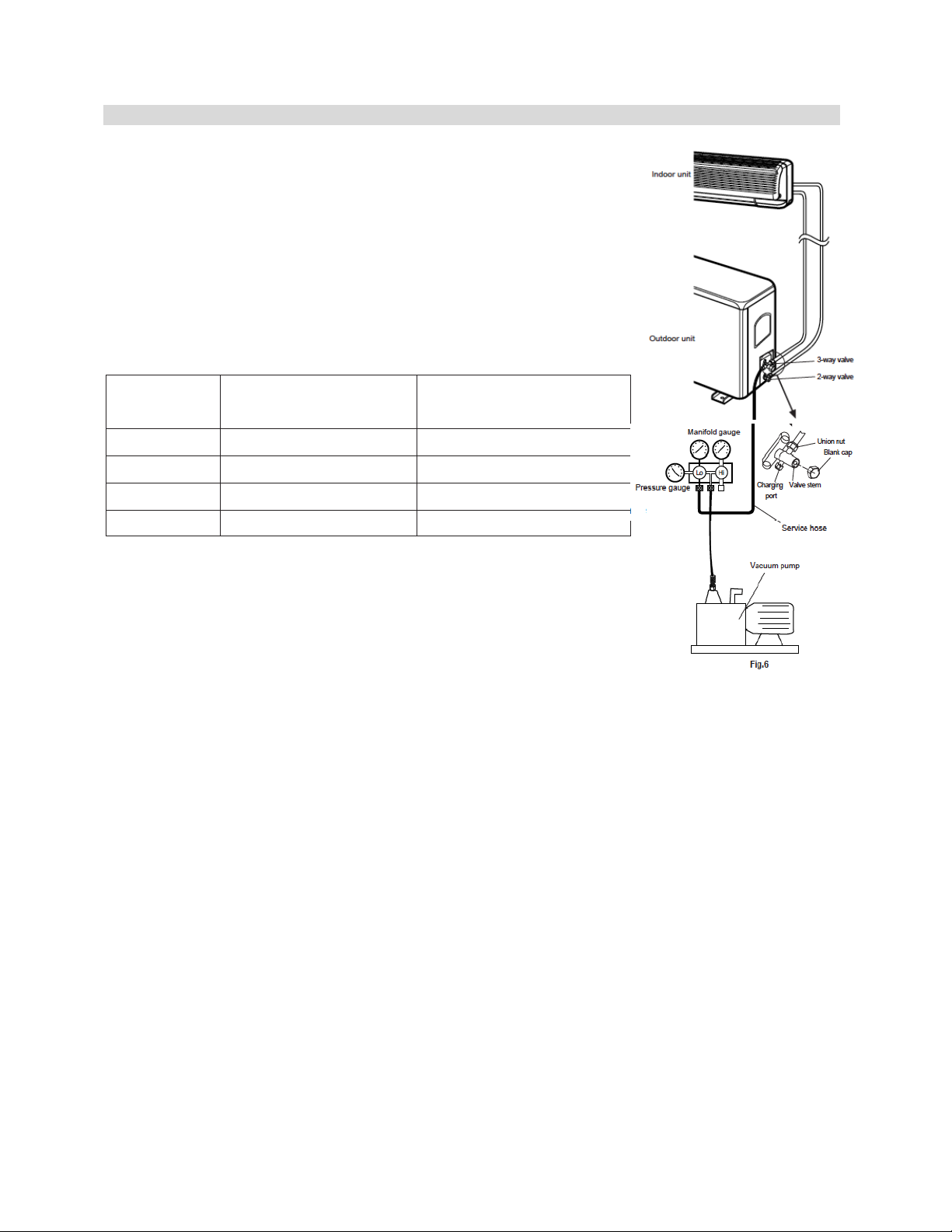

AIR PURGING WITH VACUUM PUMP

1. Check that pipelines connection have been properly connected,

remove the charging port cap, and connect the manifold gauge

and the vacuum pump to the charging valve by service hoses

as shown

2. Open the valve of the low-pressure side of manifold gauge, then run the vacuum pump.

Vacuum the indoor unit and the connecting pipes until the pressure in them lowers to

below 1.5mmHG (The operation time for vacuuming is about 10 minutes). When the

desired vacuum is reached, close the valve of the low pressure of the manifold and stop the

vacuum pump.

3. Disconnect the service hoses and fit the cap to the charging valve.

4. Remove the blank caps, and fully opens the spindles of the 2-way and 3-ways valves with

a service valve wrench.

5. Tighten the blanking caps of the 2-way and 3-ways valves, applying the above torque

Table