EN 41MAINTENANCE

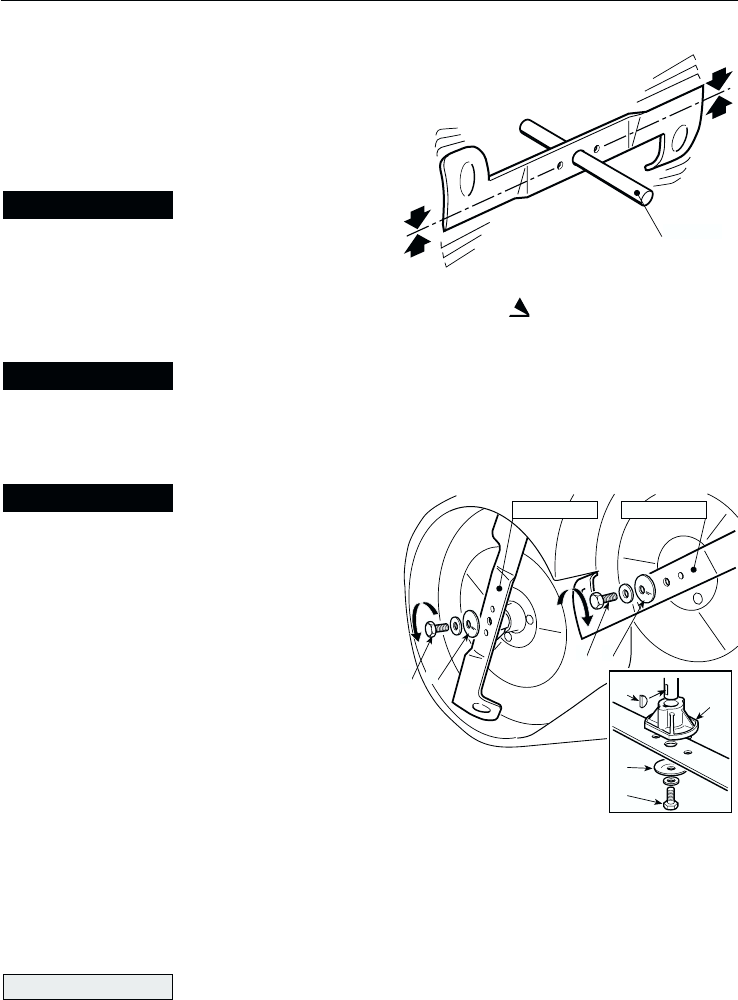

Sharpen the two cutting edges using a

medium grade grinding wheel and check

the balance by holding the blade up with

a round 18 mm Ø bar inserted in the cen-

tral hole.

Damaged or bent

blades must always be replaced;

never try to repair them! ALWAYS

USE MANUFACTURER'S GENUINE

REPLACEMENT BLADES BEARING THE SYMBOL !

The blades differ, and are contra-rotating. When instal-

ling them, make sure that they are correctly positioned by refering to the

code number marked on the outside of each one.

When re-fitting the

blades, always follow the indicated

sequence, making sure that the bla-

des' wings are facing towards the

interior of the cutting deck and that

the cupped side of the cup washer

(1) is pressing against the blade.

Fully tighten the fixing screws (2),

preferably using a torque wrench set

at 45-50 Nm. If the shaft hub (3) came

off when dismantling the blade, make

sure that the key (4) is firmly in its correct position.

6.3.2 C

UTTING DECK ALIGNMENT

The cutting deck should be properly set to obtain a good cut.

For achieving good results from cutting, the front part should

always be 5 - 6 mm lower than the rear.

– Put the machine onto a flat surface and check the tyre pressures;

NOTE

!

WARNING!

!

WARNING!

!

WARNING!